Hydraulic stop valve and application method

A shut-off valve and hydraulic technology, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of complex structure, large load of valve body, large volume, etc., achieve simple structure, prolong service life, open The effect of small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

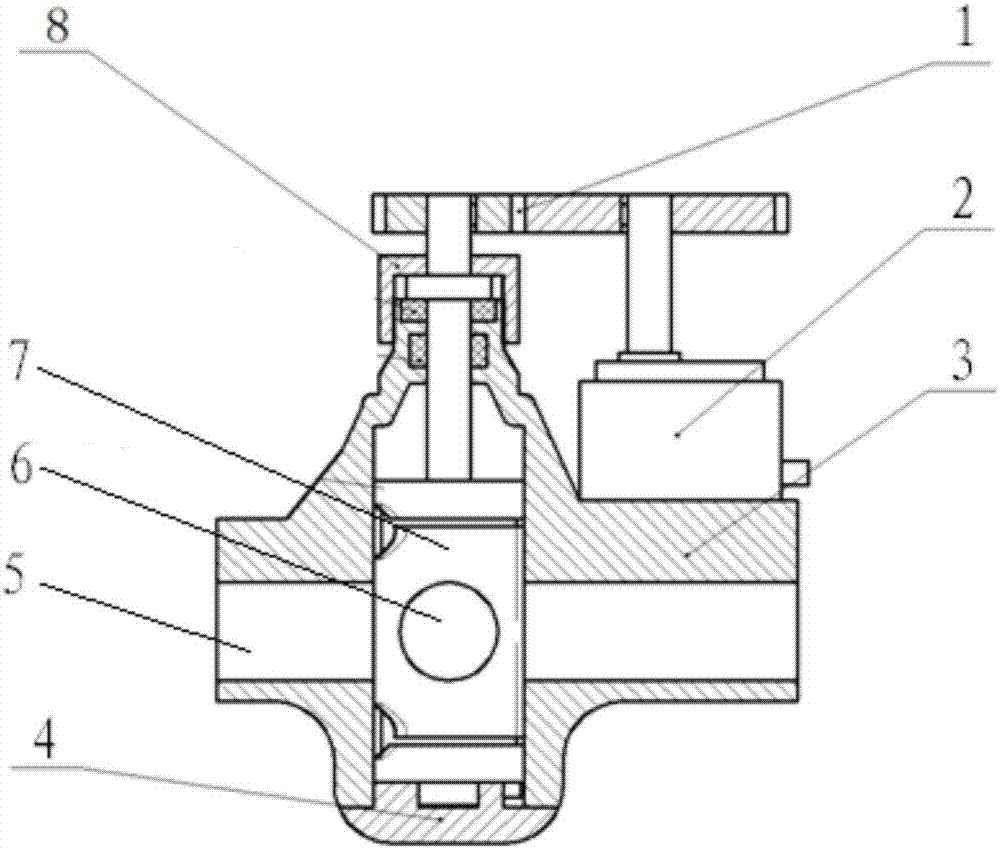

[0020] With reference to the drawings, this application is a hydraulic stop valve, which contains a valve body 3, a valve core 7, a base 4 and a gland 8. The valve body 3 has a horizontal liquid passage 5 and a longitudinal valve core cavity 9, so The said valve core 7 is embedded in the valve core cavity 9 of the valve body 3. The middle part of the valve core 7 is a cylindrical valve core body. Both ends of the valve core body are protruding valve core shafts 14, and there are protruding valve core shafts 14 in the middle of the valve core body. The through hole 6 for liquid flow in the horizontal direction is provided with an annular diversion groove 11 on the upper and lower surfaces of the valve core body. The side surface of the valve core body perpendicular to the direction of the through hole 6 has a longitudinal diversion groove connected to the annular diversion groove. Groove 10, on the other side surface of the valve core body, the upper and lower annular diversion g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com