Novel butterfly valve

A butterfly valve, a new type of technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of increasing the number of parts, the sealing structure is easy to wear, and increasing the cost of use, so as to reduce wear and extrusion, smooth flow, reduce The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

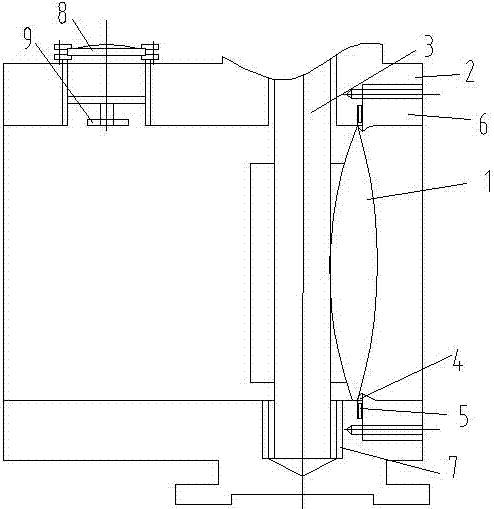

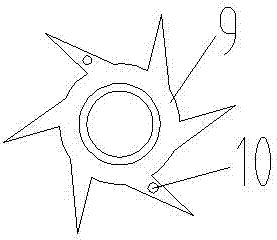

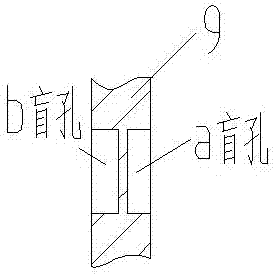

[0028] Such as figure 1 , figure 2 and image 3 The new butterfly valve shown includes: butterfly plate 1, valve body 2, valve stem 3, sealing ring 4, spring set 5, fixed ring 6, water guide bearing 7, sight glass 8, runner 9 and indicator light 10, all The valve stem 3 passes through the top of the valve body 2 and is vertically installed in the valve body 2. A water guiding bearing 7 is arranged between the bottom of the valve stem 3 and the valve body 1. The material of the water guiding bearing 7 can be a non-metallic material. Polyurethane is usually used, and a disc plate 1 is installed in the middle of the valve stem 3. The disc plate 1 is arranged in the flow channel. The disc plate 1 includes a mounting cylinder and a convex body. Install the cylinder, fix the installation cylinder on the valve stem 3; the center line of the installation cylinder, the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com