Unloading vehicle having anti-scattering device

An unloading truck and anti-sprinkling technology, which is applied in the arrangement of loading and unloading vehicles, vehicles used for freight, vehicles with inclined bearing movement, etc. Ground staff and other problems, to achieve the effect of novel structure, convenient use, and prevention of scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

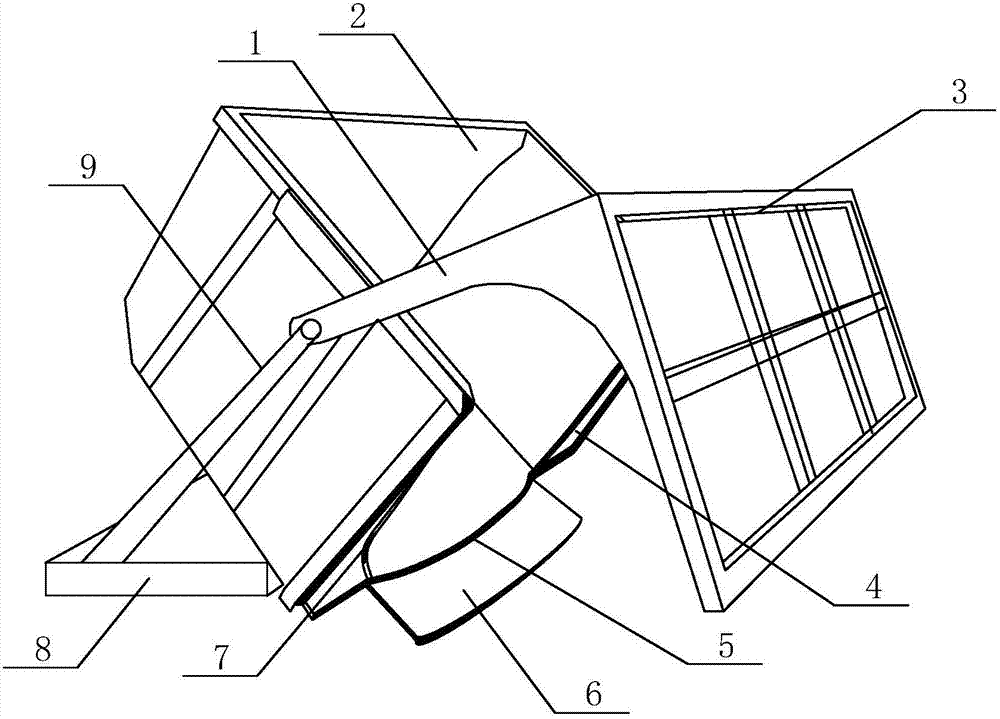

[0017] Such as figure 1 As shown, the unloading car with the anti-sprinkling device of the present invention includes a car body 2, the lower end of the car body 2 is provided with a chassis 8, and the car body 2 includes a wing plate, a bottom plate, a side plate and an unloading door 3, and the car body 2 The interior of the buffer partition 7 is provided with a buffer partition 7, one end of the buffer partition 7 is fixed on the bottom plate, the other end is fixed on the side plate, a buffer medium 4 is provided between the buffer partition 7 and the car body 2, and an inner Groove 5, one side of the bottom plate is provided with an arc plate 6, the arc plate 6 is adapted to the position of the inner groove 5, the upper end of the unloading door 3 is provided with a rotating rod 1, and the rotating rod 1 is connected to the chassis through a transmission shaft 9 8, is fixedly connected with the cylinder on the chassis 8.

[0018] Wherein, the buffer partition 7 is arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com