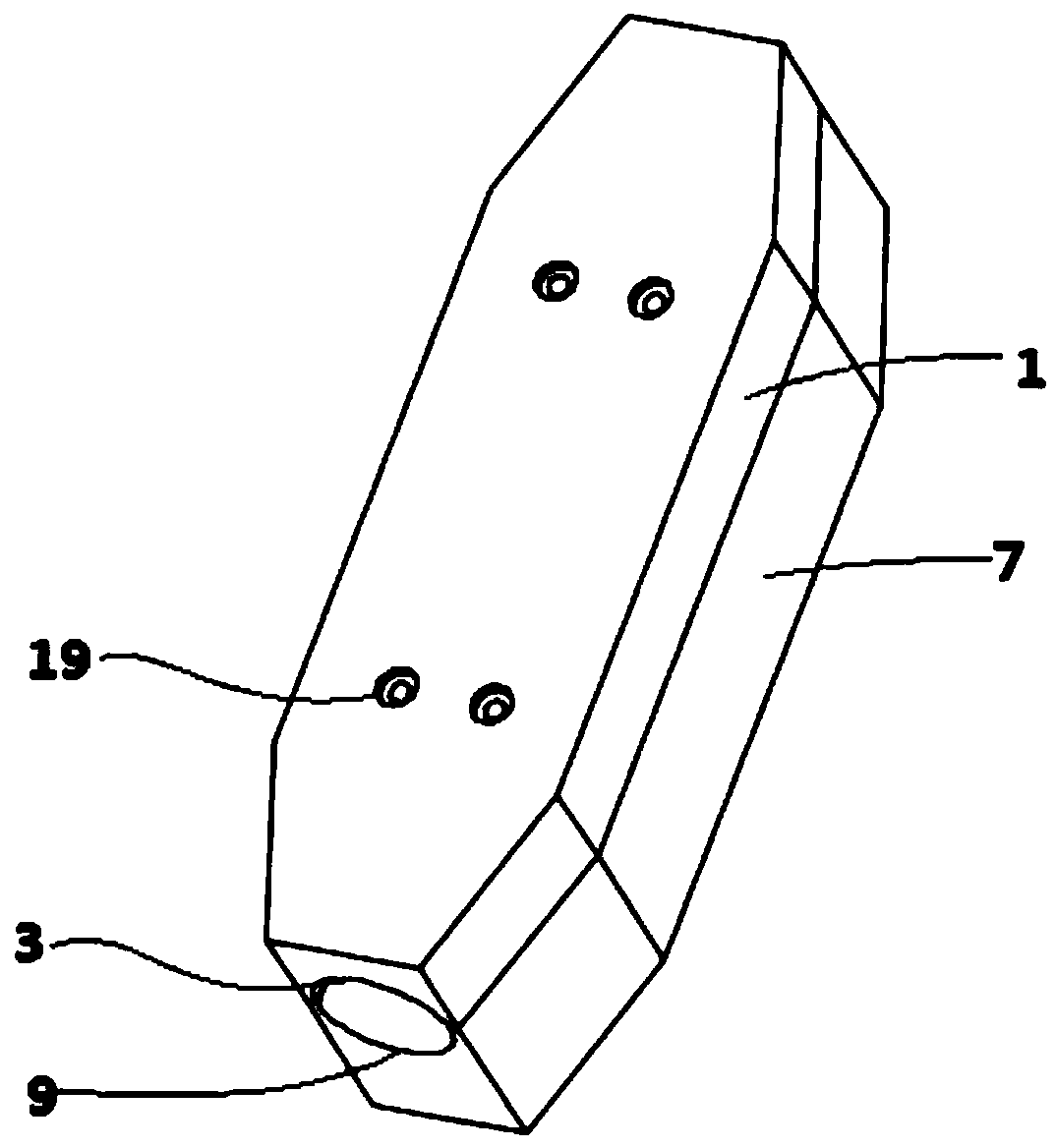

A junction box based on line connector connection

A joint connection and junction box technology, applied in the direction of electrical components, etc., can solve problems such as low structural strength and poor sealing of wire joints, and achieve the effects of improving structural strength, good insulation performance, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

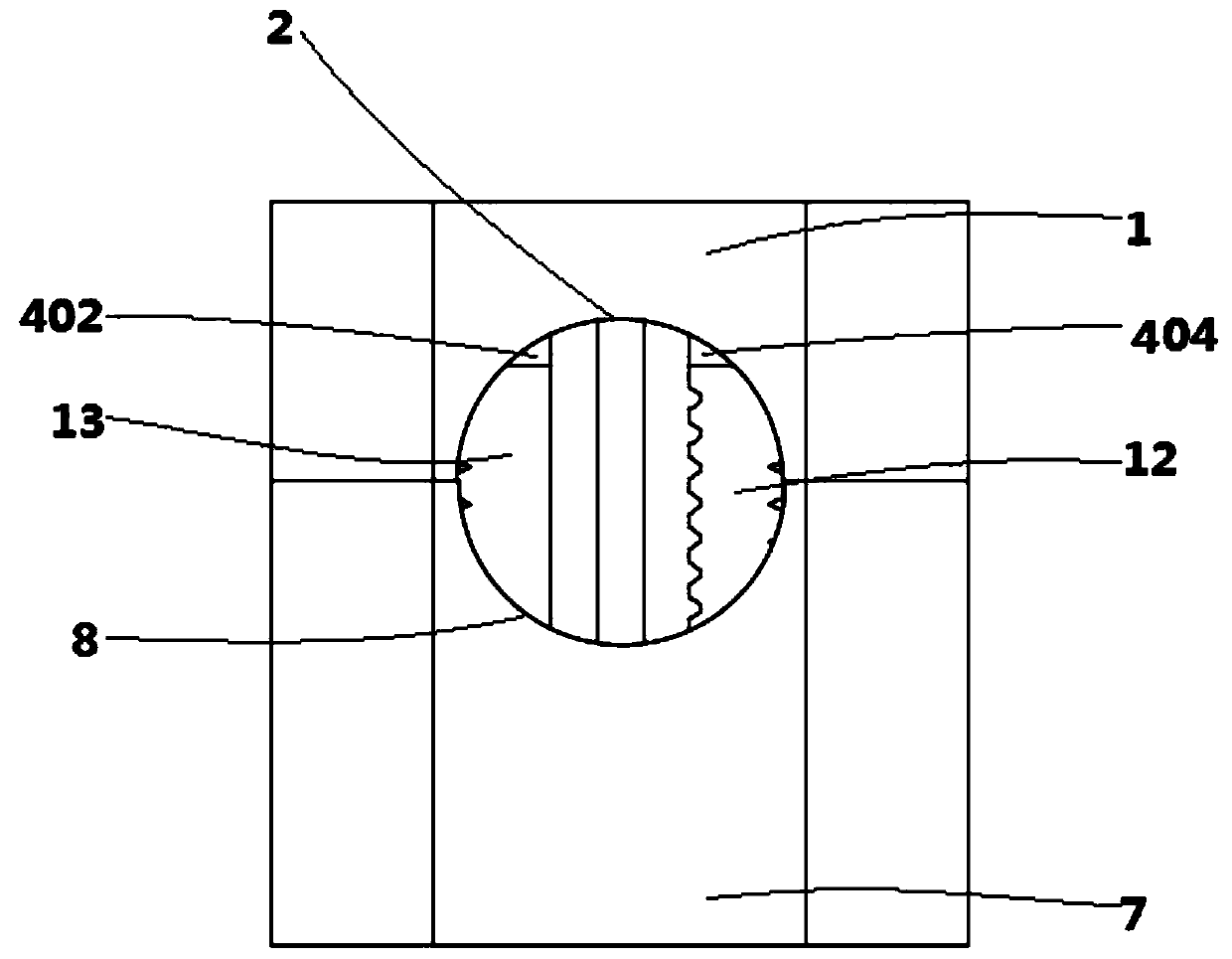

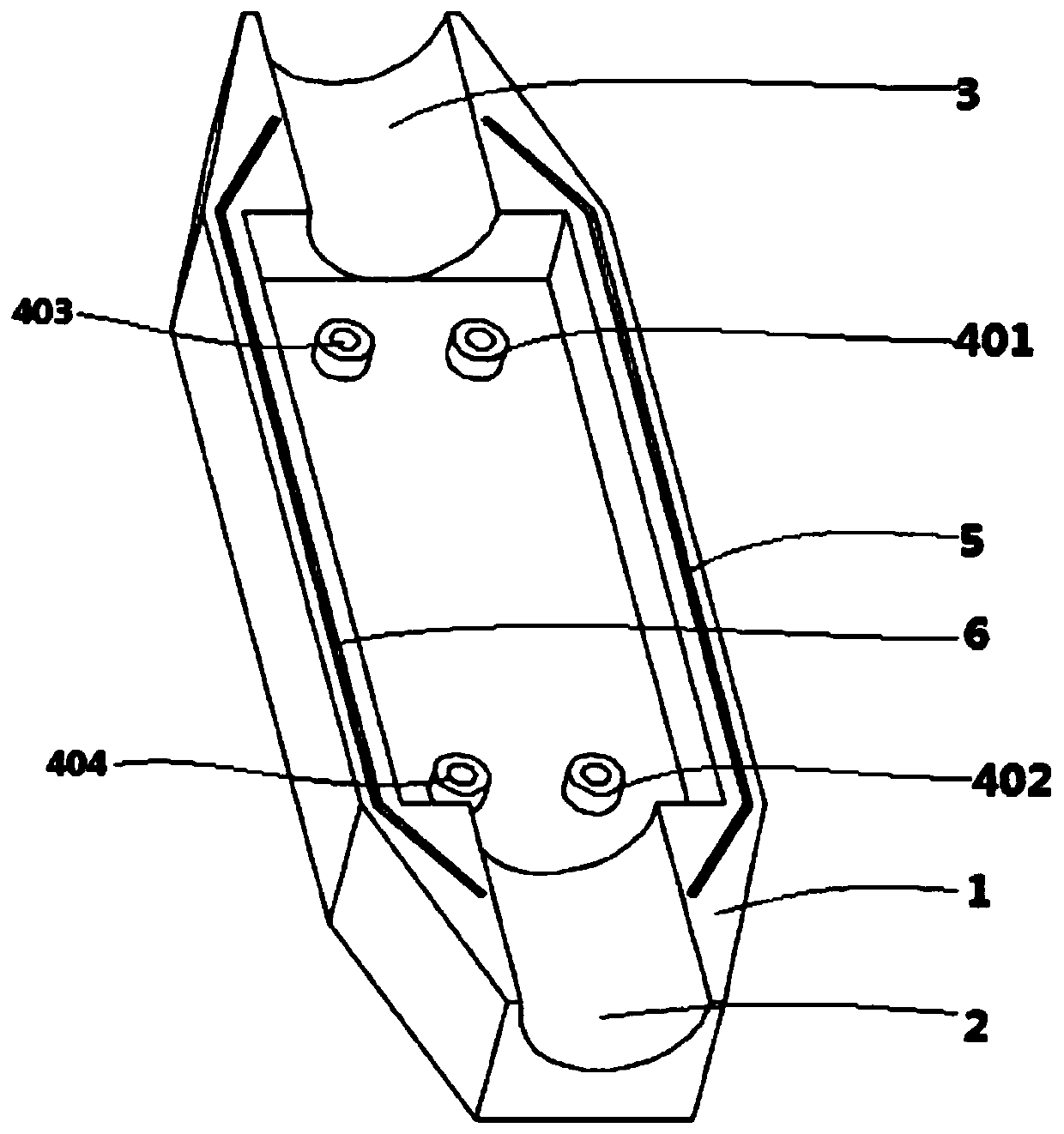

[0053] Wherein, the distance between two adjacent grooves 1203 is 0.3CM, the distance between adjacent fixing grooves 13A is 0.3CM, and the distance between two adjacent grooves 1202 is 0.5CM.

[0054] Wherein, the wire is wound 2 turns around the first limiting post 12 through the groove 1202 on the first limiting post 15, and at the same time, it is also wound 2 turns around the second limiting post 15, and passes through the first snap ring 17, and the second snap ring 18. The function of the first fixing column 13 and the second fixing column 14 is to prevent the electric wire from winding back and strengthen the fixing of the electric wire and the box.

[0055] Wherein, the inner side of the first snap ring 17 is matched with the groove 1203 of the first limiting post 12 and the fixing groove 13A of the first fixing post 13 respectively.

[0056] Wherein, the first clamping slot 5 is matched with the first clamping block 10 , and the second clamping slot 6 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com