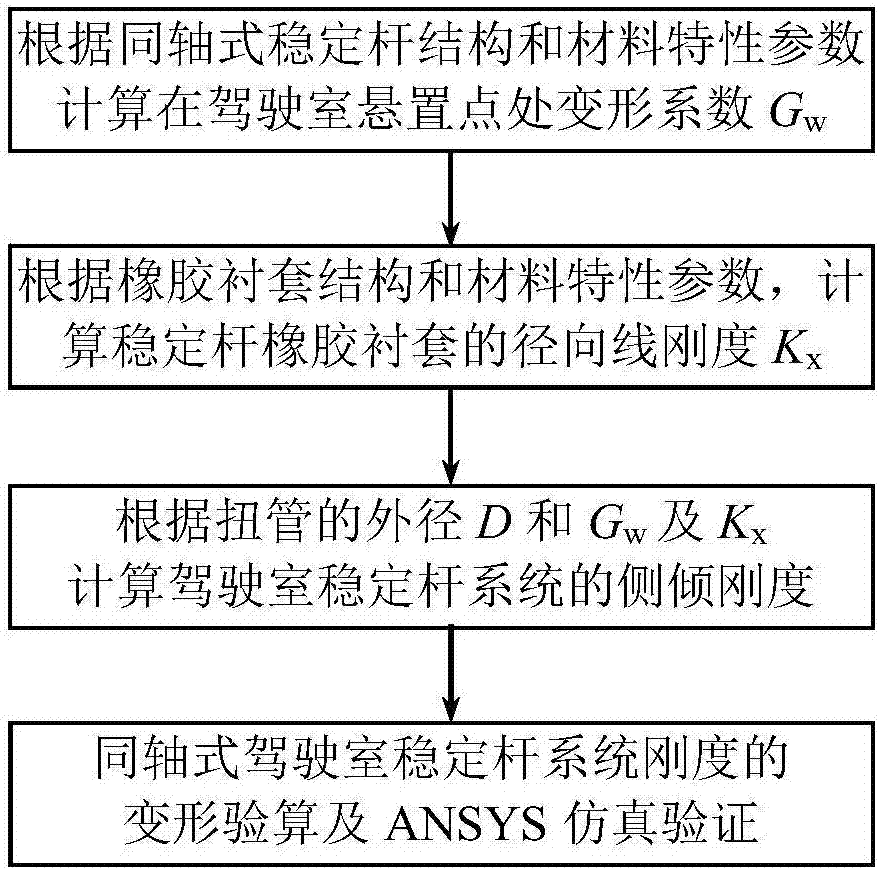

Method for checking rolling angle stiffness of cab stabilizer bar system

A technology of stabilizer bar system and roll angle stiffness, which is applied in special data processing applications, instruments, electrical and digital data processing, etc. The effect of product development speed, improving design level and quality, and reducing design and test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

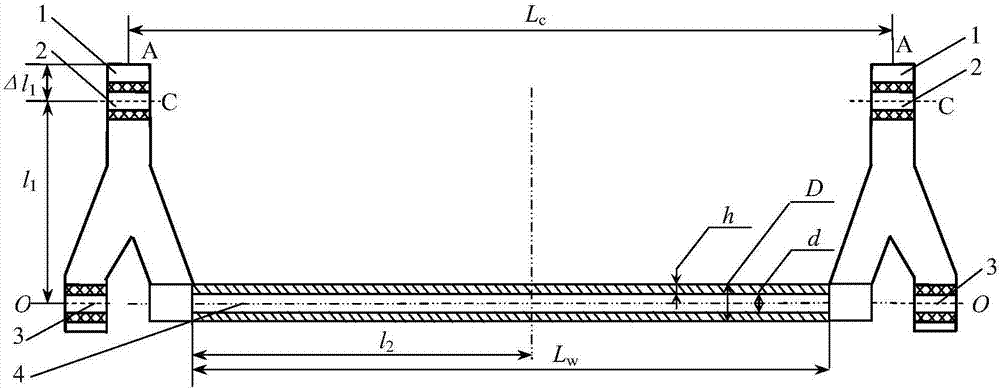

[0044]Embodiment 1: The structure of a coaxial cab stabilizer bar system is left-right symmetrical, such as figure 2 As shown, it includes: swing arm 1, suspension rubber bushing 2, torsion rubber bushing 3, torsion tube 4; wherein, torsion tube 4 and torsion rubber bushing 3 are coaxial; the distance between the left and right swing arms 1 L c =1550mm, that is, the suspension distance of the stabilizer bar; the distance l between the suspension rubber bushing 2 and the torsion rubber bushing 3 1 =380mm, that is, the length of the swing arm; the distance from the suspension position C of the swing arm to the outermost end A is Δl 1 =47.5mm; the length L of the twisted tube 4 w =1500mm, that is half the length l of the torsion tube 2 = L w / 2=750mm; the inner diameter of the torsion tube d=35mm, the outer diameter D=50mm; the elastic modulus of the torsion tube material E=200GPa, Poisson’s ratio μ=0.3; the structure and material properties of the four rubber bushes on the ...

Embodiment 2

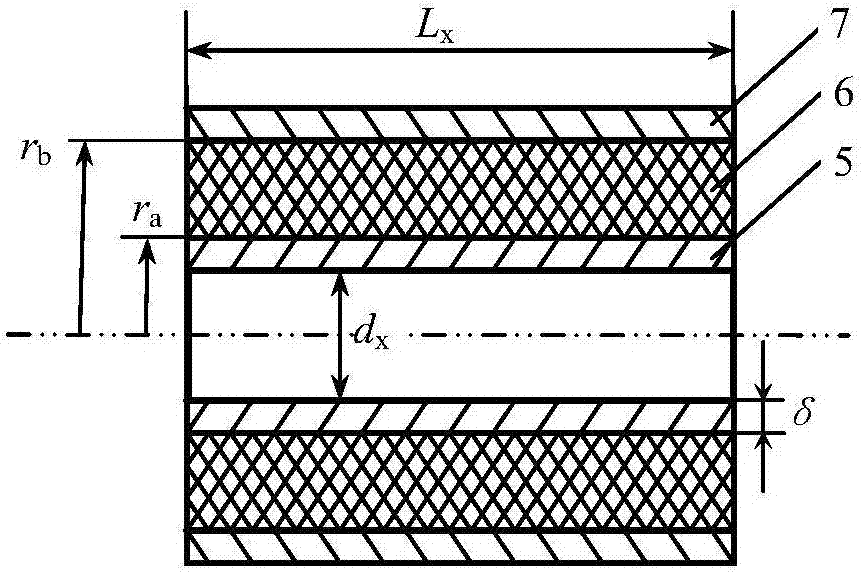

[0085] Embodiment 2: The structure of a coaxial cab stabilizer bar system is left-right symmetrical, such as figure 2 As shown, the distance L between the two swing arms c =1400mm, that is, the suspension distance of the stabilizer bar; the distance l between the suspension rubber bushing 2 and the torsion rubber bushing 3 1 =350mm, that is, the length of the swing arm; the distance from the suspension position C of the swing arm to the outermost end A is Δl 1 =52.5mm; the total length L of the torsion tube 4 w =1000mm, that is, half the length l of the torsion tube 2 = L w / 2=500mm, inner diameter d=42mm, outer diameter D=50mm; the structure and material properties of the left and right four rubber bushes are exactly the same, as image 3 Shown, wherein, the inner diameter d of the inner cylindrical sleeve 5 x =35mm, wall thickness δ=5mm; length L of rubber sleeve 6 x =40mm, inner circle radius r a =22.5mm, outer circle radius r b=37.5mm; The material properties of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com