Staggered stacking structure for heat exchange pipes

A technology of heat exchange tubes and horizontal tubes, applied in the field of staggered superposition structure of heat exchange tubes, can solve problems such as temperature measurement error, uneven temperature distribution, unsuitable heat release, etc., and achieve the effect of avoiding local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

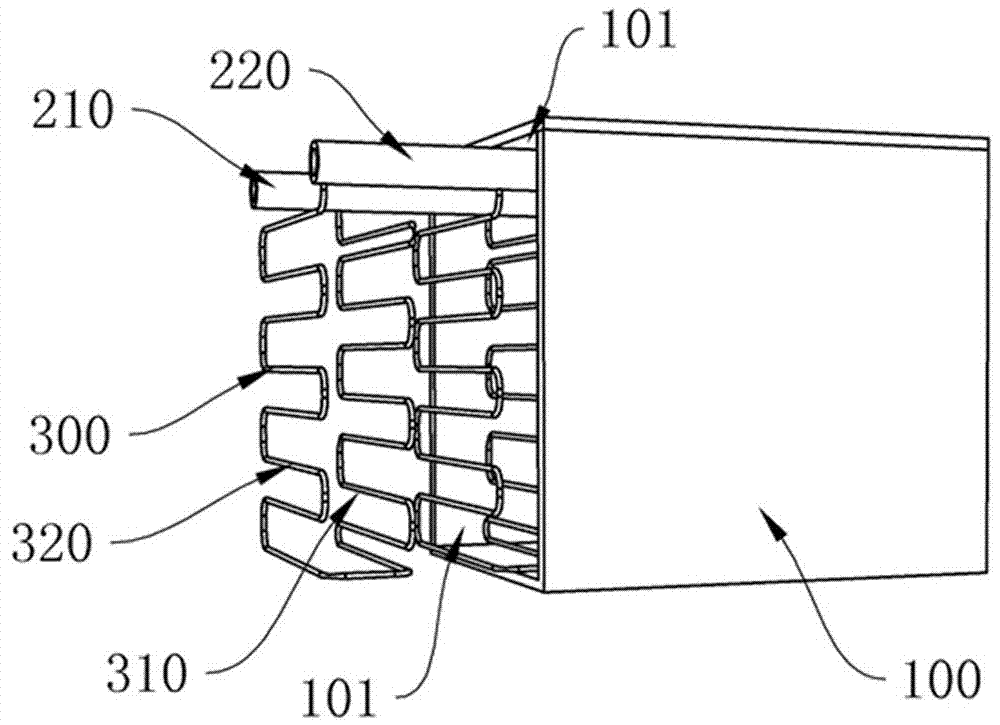

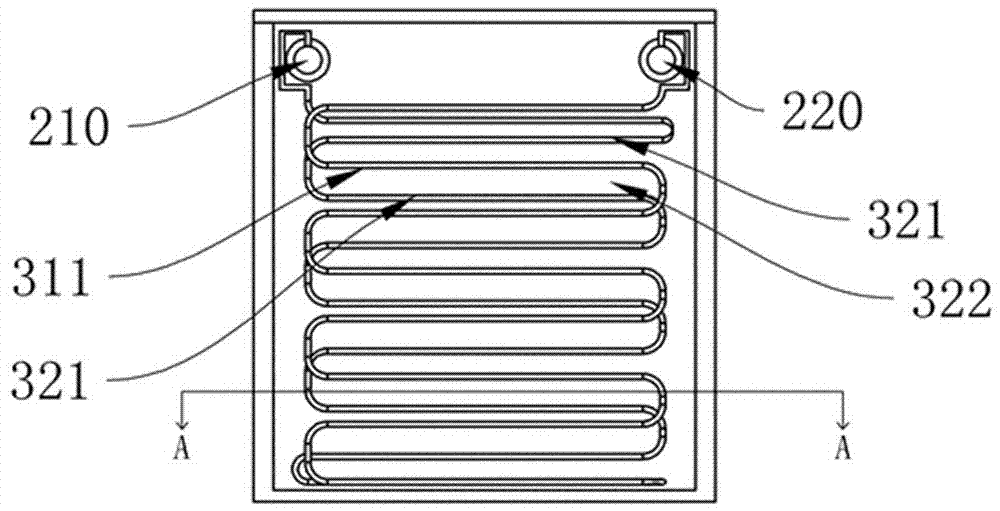

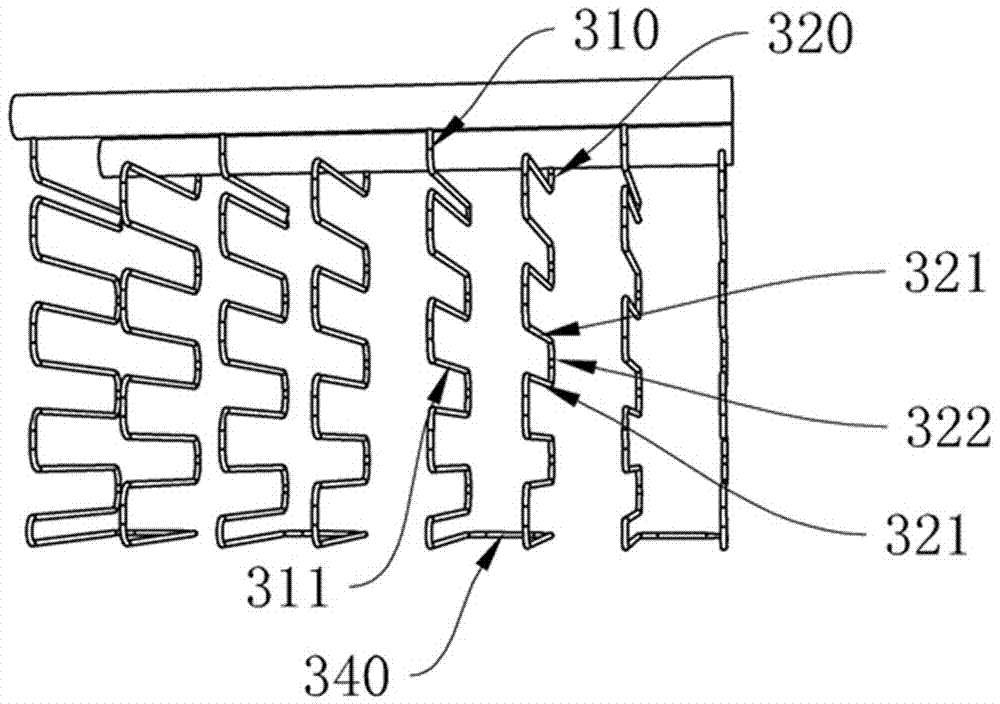

[0025] see Figure 1-Figure 3 , a staggered stacking structure of heat exchange tubes, including inlet headers 220, outlet headers 210, and heat exchange tubes 300, the inlet headers 220, outlet headers 210, and heat exchange tubes 300 are all installed in the housing In the inner cavity 101 of 100, the inner cavity 101 is filled with a phase change material and a pressure relief space is reserved (the entire inner cavity is not filled, and a space is provided for the phase change of the phase change material to reduce the impact of the phase change material on heat transfer tube stress);

[0026] There are multiple heat exchange tubes, which are evenly distributed in the axial direction of the inlet header 220 and the outlet header 210 .

[0027] The heat exchange tube 300 includes a descending portion 310 and an ascending portion 320, and the descending p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com