Double-row angular contact ball bearing and machining technology thereof

A double-row angular contact and processing technology, which is applied to rolling contact bearings, bearings, bearing components, etc., can solve problems such as large loads, achieve volume reduction, improve work efficiency, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

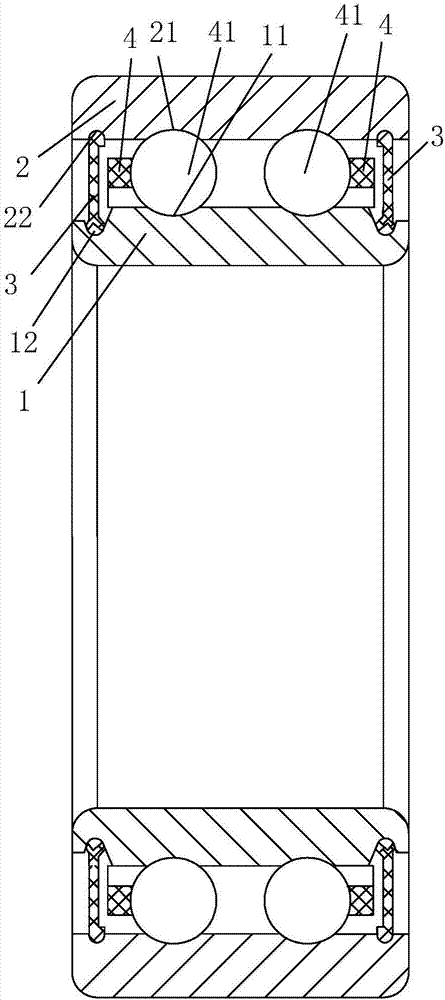

[0036] Example: such as figure 1 As shown, a double-row angular contact ball bearing includes a concentric inner ring 1 and an outer ring 2. The outer recess of the inner ring 1 is provided with two parallel inner grooves 11, and the inner recess of the outer ring 2 is provided with inner and inner grooves. The outer channel 21 opposite to the channel 11, the steel ball 41 that fits the outer channel 21 and the inner channel 11 and rotates between the inner ring 1 and the outer ring 2 is arranged, and the steel balls 41 of the same ring are held by a ring Frame 4 is fixed.

[0037] Such as figure 1 As shown, the inner ring 1 is provided with inner card slots 12 respectively recessed on both sides along its own thickness direction, and the outer ring 2 is provided with outer card slots 22 respectively recessed on both sides along its own thickness direction. The corresponding inner card slots 12 and A sealing ring 3 is arranged between the outer card slots 22 . The design of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com