Fluorinated polyether siloxane and preparation method of same

A technology of fluorinated polyether siloxane and fluorinated polyether, which is applied in the field of fluorinated polyether siloxane and its preparation, can solve the problem that the compound coating does not show sufficient oil repellency and lubricity, and affects the substrate adhesion. Bond strength, unfavorable industrial production and other issues, to achieve full cross-linking and curing, easy control of the preparation process, and good antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

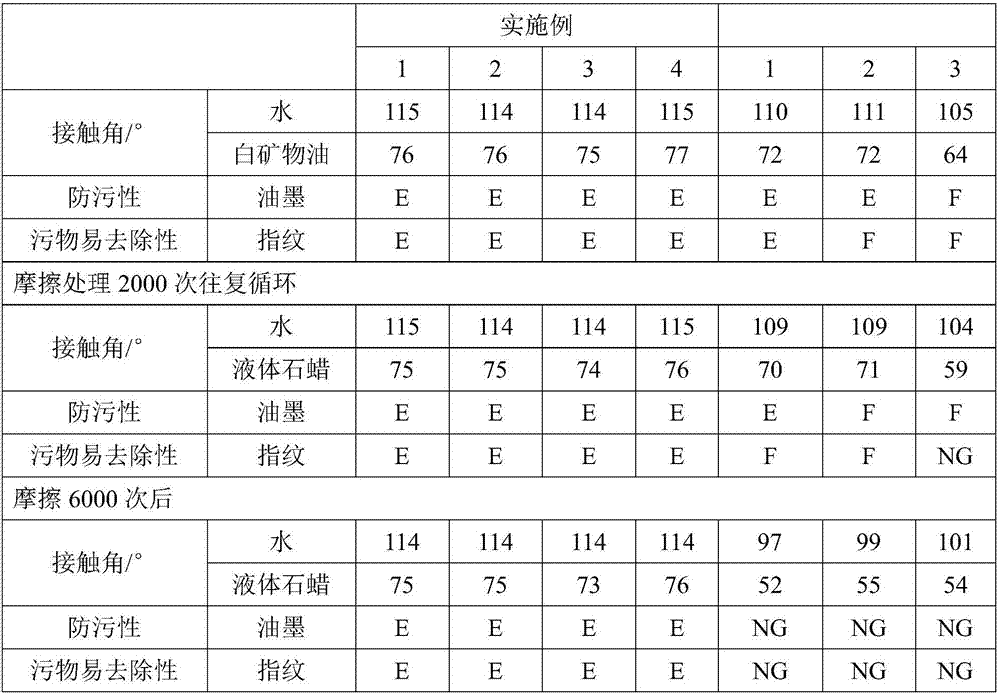

Examples

preparation example Construction

[0033] The preparation method of fluorinated polyether siloxane includes the following steps:

[0034] (1): The polyfluoropolyether methyl monoformate is reacted with a multifunctional amino compound to prepare the amidation product of the polyfluoropolyether. A polyfunctional amino compound is an organic compound containing 1 to 2 primary amino groups and 2 hydroxyl groups in one molecule or an organic compound containing 1 to 2 primary amino groups and 2 secondary amino groups in one molecule, and among them, 2- Amino-1,3-propanediol, 2-amino-2-methyl-1,3-propanediol and trivinyltetraamine, etc. When the reactant is a monoprimary amine compound, the molar amount can be 1 to 1.2 times the polyfluoropolyether monoformate to complete the reaction of the polyfluoropolyether monoester; when the reactant is a diprimary amine compound, The molar amount of ether methyl ester is preferably controlled at 1:2. The reaction is preferably carried out under the protection of nitrogen, and ...

Embodiment 1

[0043] Example 1 (Synthesis of fluorinated polyether siloxane compound a-a-1)

[0044] Step (1): 103.16g (about 0.02mol) of polyfluoropolyether methyl monocarboxylate F (CF (CF 3 )CF 2 O)nCF(CF 3 )COOCH 3 , N=30 and 2.18g (about 0.024mol) of 2-amino-1,3-propanediol were added into the reaction flask, and under the protection of nitrogen, the temperature was raised to 75°C, and the reaction was stirred for 20h. FTIR analysis confirmed the ester group absorption peak (about 1790cm -1 ) Disappeared, and the amide group absorption peak (about 1710cm -1 ). The product was dissolved in 100 g of ethyl tert-butyl ether, and 10 ml of 1 mol / L HCl aqueous solution was added, stirred for 10 minutes, and then stood at room temperature for liquid separation, and the water phase was removed. After washing the organic phase with deionized water to neutrality, and then drying with magnesium sulfate, and then steaming the solvent with a rotary evaporator, the product F(CF(CF 3 )CF 2 O)nCF(CF 3 )CO...

Embodiment 2

[0047] Example 2 (Synthesis of fluorinated polyether siloxane compound a-a-2)

[0048] Step (1): In addition to polyfluoropolyether methyl monoformate, use 50.04g (about 0.02mol) of F(CF(CF 3 )CF 2 O)nCF(CF 3 )COOCH 3 , N=14 instead, 2-amino-1,3-propanediol was replaced with 2.52g (about 0.024mol) of 2-amino-2-methyl-1,3-propanediol, and the rest was the same as the step (1 ) Is the same, the resulting product F(CF(CF 3 )CF 2 O)nCF(CF 3 )CONHC(CH 2 OH) 2 CH 3 , N=14.

[0049] Step (2): Except that the polyfluoropolyether glycol is replaced by 38.63g (about 0.015mol) of the product obtained in the previous step, the rest is the same as the step (2) of Example 1, to obtain the product F(CF(CF) 3 )CF 2 O)nCF(CF 3 )CONHC(CH 2 OCONHCH 2 CH 2 OOCCH=CH 2 ) 2 CH 3 , N=14.

[0050] Step (3): Except that the double bond-containing polyfluoropolyether is replaced with 28.57g (about 0.01mol) of the product obtained in the previous step, the rest is the same as the step (3) of Example 1, to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com