Floating clamping jaw self-adapting to bricking stack

A floating gripper, self-adaptive technology, applied in the direction of the lifting device, etc., can solve the problems that affect the loading and unloading efficiency, and the clamping device cannot adapt to the shape of the brick stack, so as to reduce the floating resistance and increase the floating amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

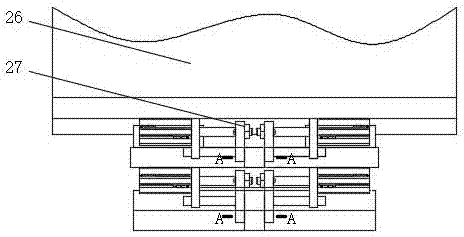

[0032] combined with Figure 1-6 As shown, a kind of floating jaw of self-adaptive bricklaying pile comprises the L-shaped hanger 1 that connects successively, floating device 2, clamping device 3; Said floating device 2 comprises the base 26 that is connected with hanger 1, Slide the linear floating plate 24 that is arranged on the base 26, rotate the circular rotary floating plate 22 that is arranged on the linear floating plate 24 and is connected with the clamping device 3; The tightening direction is parallel, and the side of the linear floating plate 24 parallel to the sliding direction of the linear floating plate 24 has a first limiting block 241 ; the base 26 is provided with a first clamping mechanism for clamping and releasing the first limiting block 241 .

[0033]In this embodiment, the hanger 1 is connected with a forklift. The clamping device 3 adopts the clamp disclosed in Chinese patent CN201210296238.4: it includes two clamping arms arranged opposite to each...

Embodiment 2

[0037] In order to better implement the present invention, the clamping device 3 can adapt to the floating of the bricklaying stack 4 along the vertical axis rotation direction. On the basis of Embodiment 1, combined with the attached Figure 1-6 Further, the rotation axis of the rotary floating plate 22 is perpendicular to the end surface of the linear floating plate 24, and the outer circular surface of the rotary floating plate 22 has a second limit block 221; The second clamping mechanism of the two limit blocks 221.

Embodiment 3

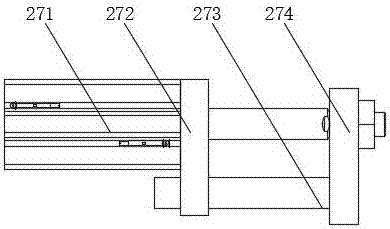

[0039] For implementing the present invention better, increase the floating amount of linear floating plate 24, on the basis of embodiment 1, in conjunction with attached Figure 1-6 Further, the first clamping mechanism is two linear mechanisms 27 with the same structure and symmetrically arranged on both sides of the first limit block 241 along the sliding direction parallel to the linear floating plate 24; the linear mechanism 27 includes a 26 fixedly connected to the oil cylinder mounting plate 272, the oil cylinder 271 detachably connected to the oil cylinder mounting plate 272, and the push block 274 fixedly connected to the piston rod of the oil cylinder 271 to push the first limit block 241 to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com