Hose punching device and hose punching method

A punching device and hose technology, applied in metal processing and other directions, can solve the problems of difficulty in forming a single row of holes, inability to use hoses, and inability to adjust the size of the storage slot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

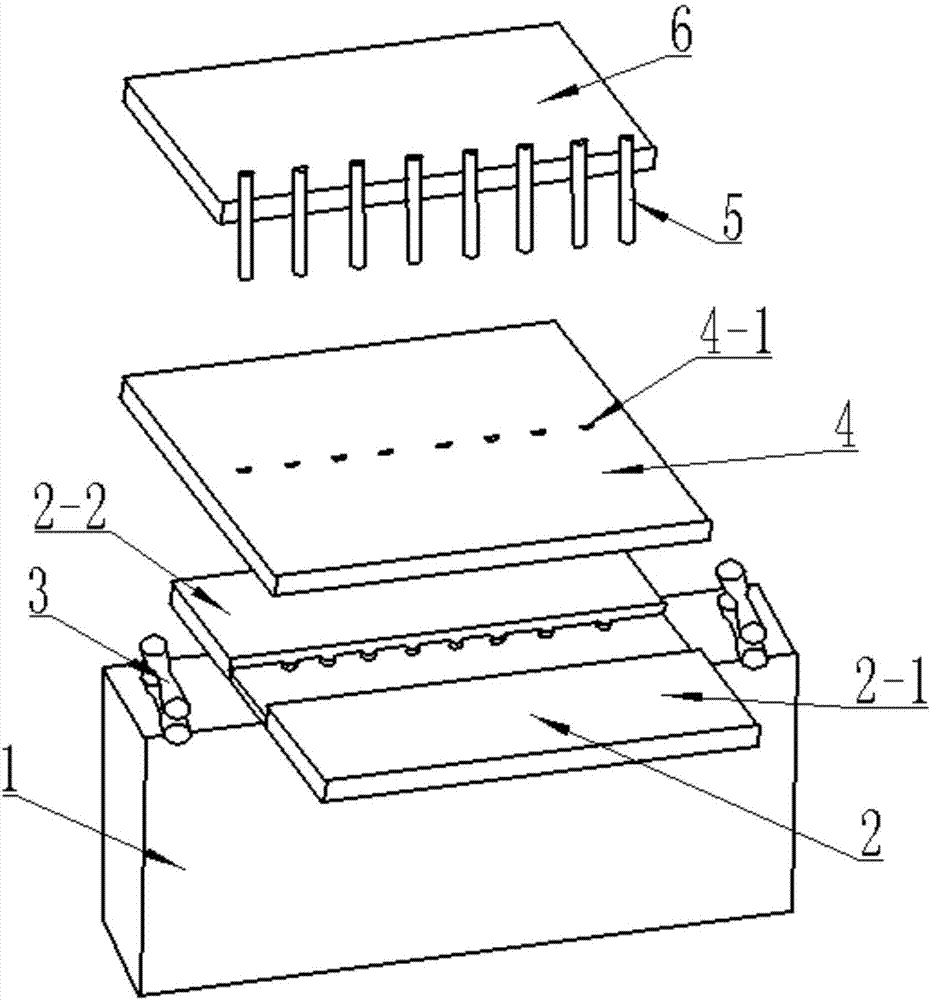

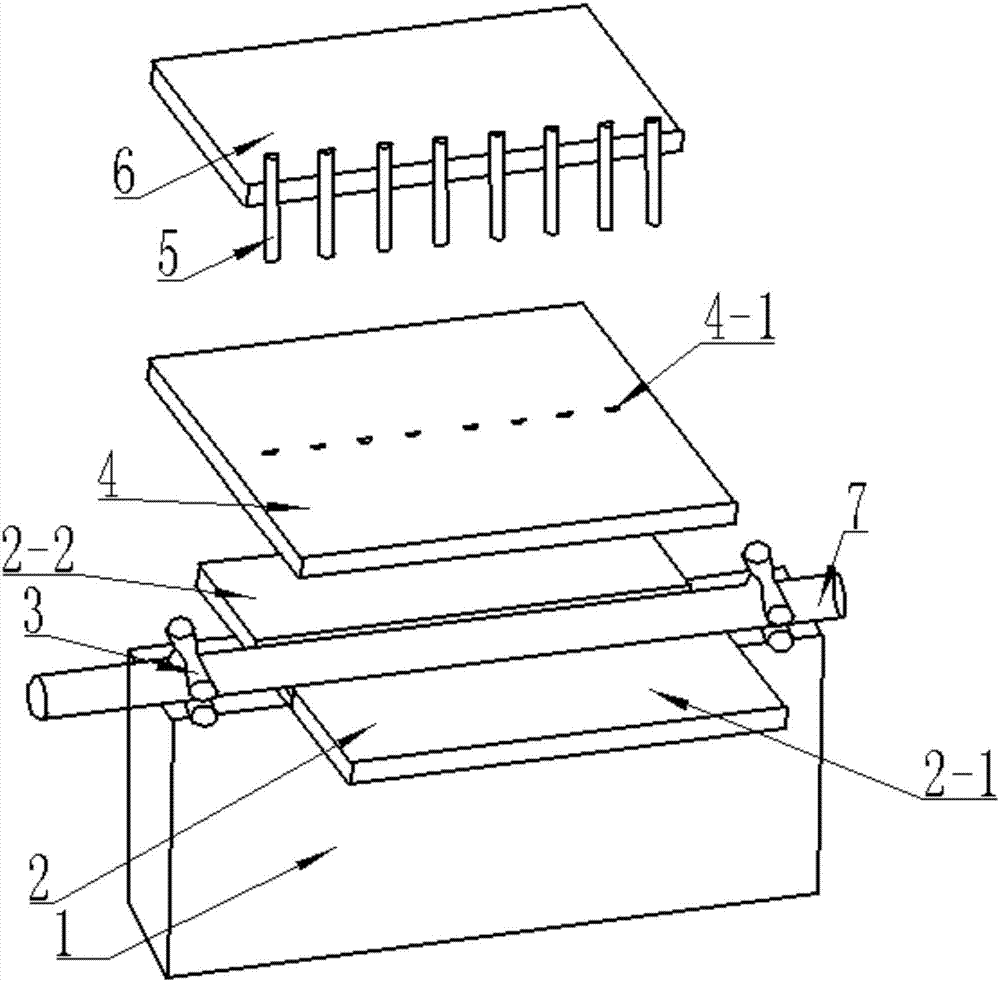

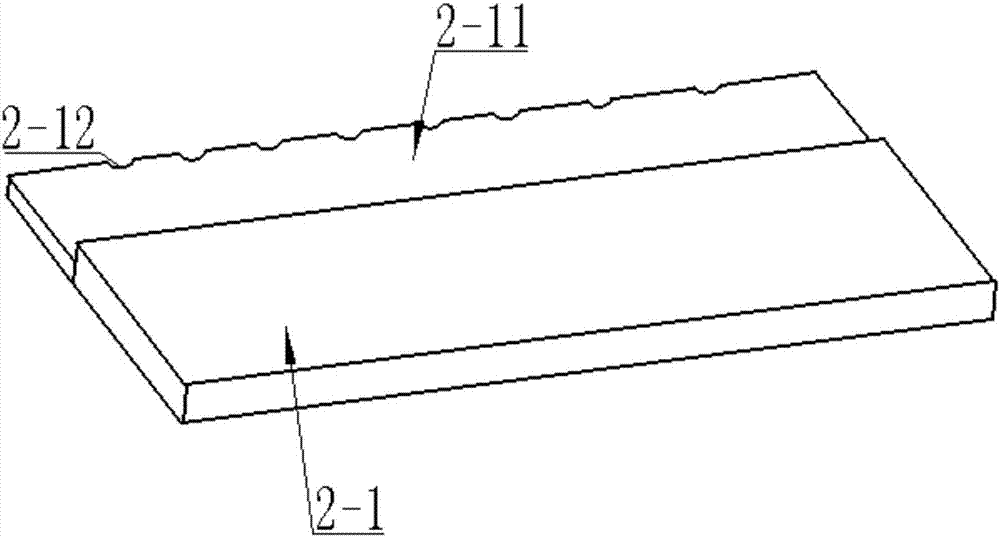

[0034] like Figure 1-Figure 4 As shown, a hose punching device includes a workbench 1, a placement plate 2, an extrusion plate 4, and a stamping plate 6, the placement plate is installed on the workbench 1, and the placement plate 2 is provided with There is a storage trough, one side of the storage trough is provided with a plurality of discharge holes 2-12, the extrusion plate 4 is arranged above the placement plate 2, and the extrusion plate 4 is provided with a plurality of The positioning hole 4-1 corresponding to the discharge hole 2-12, the stamping plate 6 is arranged above the extruding plate 4, and the stamping plate 6 is provided with a plurality of holes corresponding to the positioning hole 4-1. Corresponding to the punch 5, the discharge hole 2-12 and the positioning hole 4-1 are semicircular holes; the punch 5 includes an upper cylindrical punch 5-1 and a lower punch 5 -2, the section of the punch 5-2 is semicircular, such as Image 6 shown. The upper surfac...

Embodiment 2

[0041] The difference from Example 1 is that the lower end of the extruding plate 4 is provided with a protrusion (not shown in the figure) that is compatible with the storage slot, and the width of the storage slot is the same as that of the hose. 7 to match the diameter.

[0042] The working principle of the present invention is as follows:

[0043] When punching holes on the hose 7, firstly, the hose 7 is pulled by the tractor, so that the hose 7 passes through the guide wheel 3, and after entering the storage tank, the tractor stops working and triggers the extrusion plate cylinder to make the extrusion plate 4 downward Movement compresses the hose 7; then, triggers the punching plate cylinder, so that the punching plate 6 drives the punch 5 to move downward, punching the hose 7 to form a single row of round holes, after punching the holes, the extrusion plate 4 moves upward quickly; finally , repeat the preceding steps until the punching of the hose 7 is completed.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com