Thread clamp

A technology of clamping and loading devices, which can be used in transportation and packaging, textiles and papermaking, thin material processing, etc., and can solve problems such as dirt sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

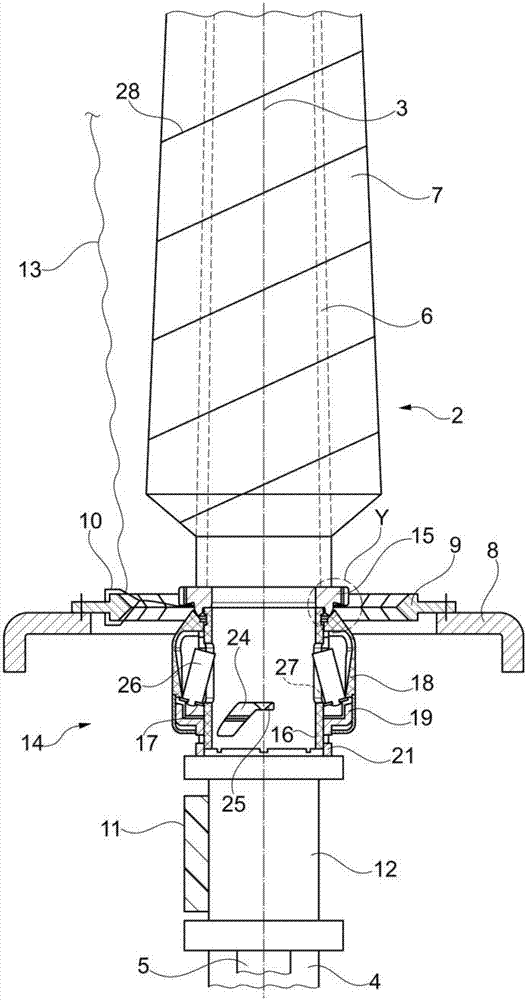

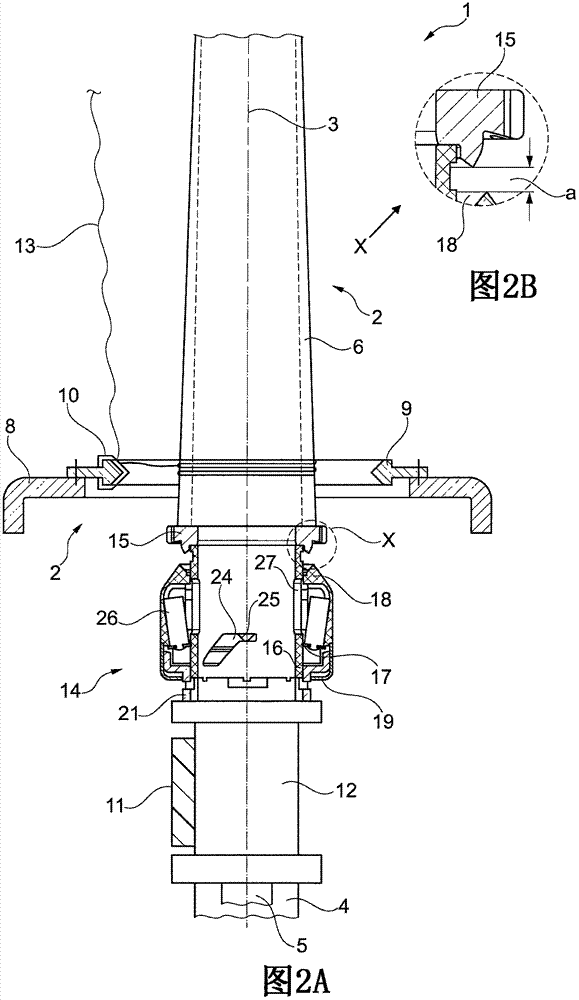

[0079] It is known that many textile machines, especially ring spinning machines or twisting machines, usually have a plurality of identical spinning stations 1 which are arranged at a short distance from one another on the machine longitudinal sides of the textile machine.

[0080] The spinning station 1 of the ring spinning machine shown in the figures has a rotatably mounted driven spindle 2, which is used for the purpose of providing yarn 13 fed by an upstream (not shown) drafting system. Certain yarns are twisted and wound onto spinning bobbins 6 . The spindle 2 of a ring spinning machine or twisting machine is usually driven by a single electric motor or, as in the exemplary embodiment, by means of a rotating drive belt 11 which loads the spindle disk 12 of the spindle 2 (so-called envelope drive) .

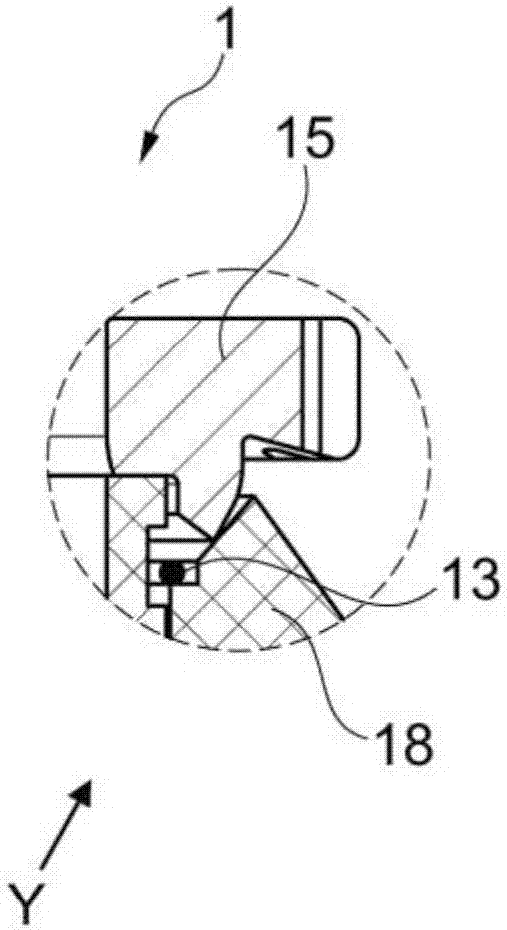

[0081] Such as Figure 1A and Figure 2A As shown, each such spindle 2 has a rotatably mounted upper spindle part 3 and a non-rotating bearing housing 4 which is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com