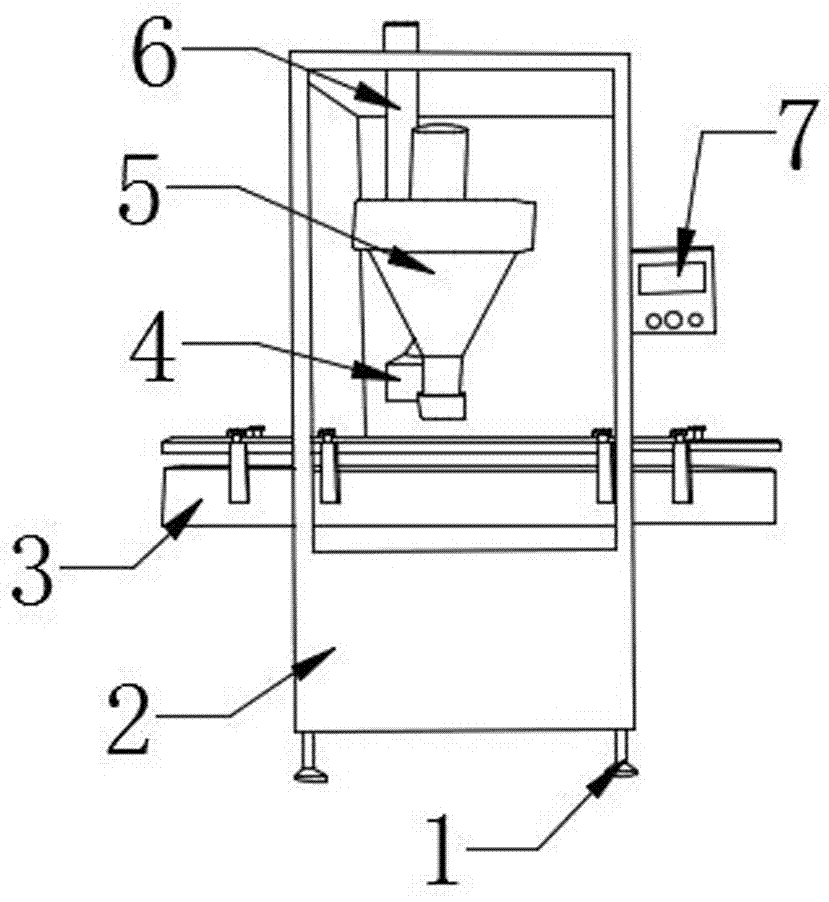

Full-automatic milk powder can filler

A canning machine, fully automatic technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the inconvenient packaging of canned milk powder of different specifications, the milk powder canning machine does not have automatic cleaning, and the inconvenient cleaning of residues in the storage hopper and other problems, to achieve the effect of improving the convenience of use, high reliability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

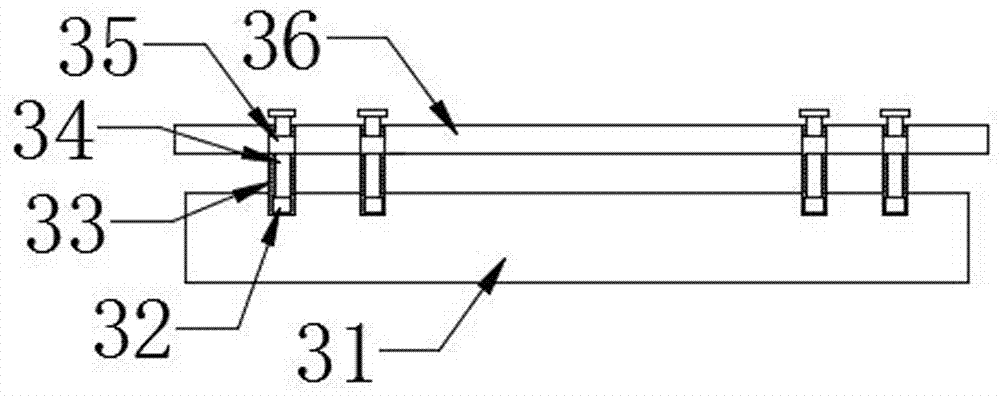

[0025] The specific embodiment: the staff rotates the hand wheel on the upper end surface of the screw mandrel 34, the rotation of the hand wheel drives the screw mandrel 34 to rotate, and the rotation of the screw mandrel 34 realizes that the ball nut 35 moves up and down along the screw mandrel 34, because the ball nut 35 passes through the bearing seat and the adjustment The plate 36 is fixedly connected, and the ball nut 35 moves up and down to adjust the position of the adjusting plate 36 up and down, so as to facilitate the adjustment of the distance between the delivery pipe 31 and the adjusting plate 36, and facilitate the packaging of canned milk powder of different specifications, which improves the present invention. Ease of use.

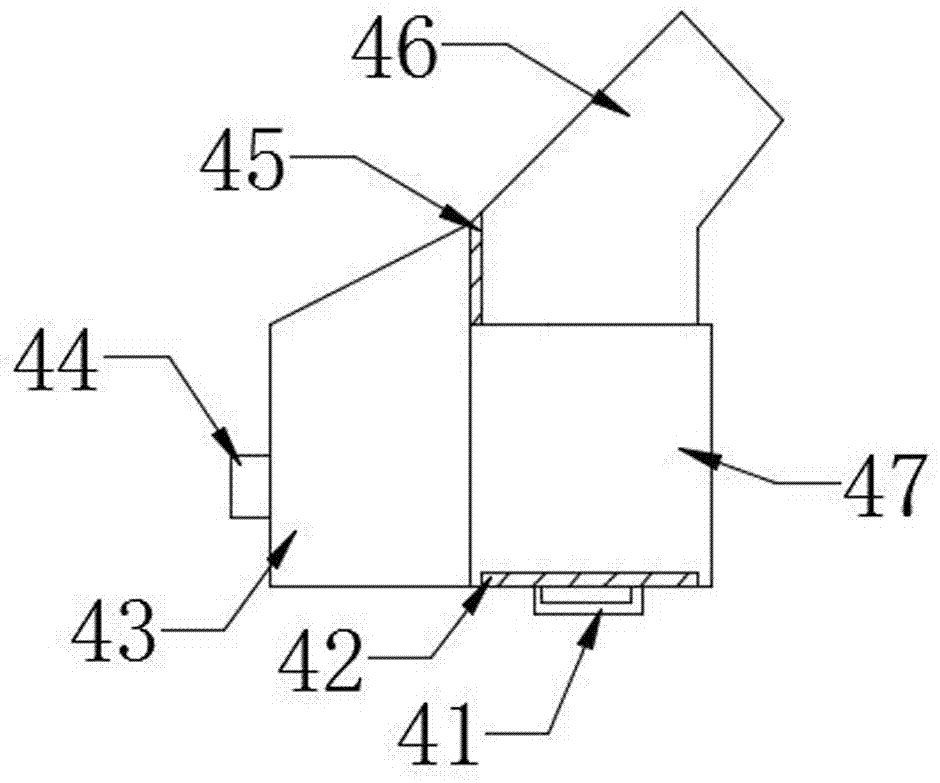

[0026] The staff turns on the cleaning switch 44, the external power supply transmits the electricity to the air extractor 43 through the wire, the air extractor 43 starts to work, and the air extractor 43 draws air through the exhaust pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com