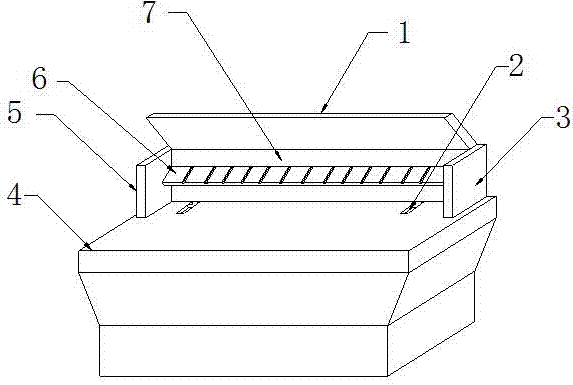

Lathe splash-proof device for industrial machine

A technology of industrial machinery and lathes, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of coolant splash, limited splash-proof range, inconvenient disassembly, etc., to achieve reasonable structure, good splash-proof effect, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

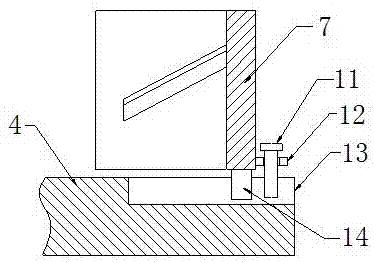

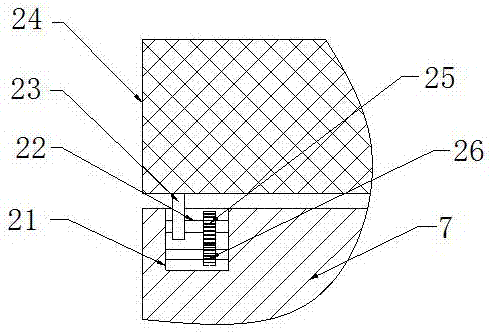

[0023] Specific implementation method: the operator first assembles the T-shaped slider 14 on the rear splash guard 7 in the T-shaped groove 13, and then pushes the rear splash guard 7 by the handle, and the rear splash guard 7 drives the T-shaped slider 14 in the T-shaped groove 13. Move inside the T-shaped slot 13, and then the rear splash guard 7 moves on the machine tool body 4. After the rear splash guard 7 moves to a suitable position, the operator tightens the positioning bolt 11, and then the positioning bolt 11 fixes the rear splash guard 7 On the machine tool body 4, when the present invention needs to be disassembled, the operator unclamps the positioning bolt 11, and pushes the rear splash guard 7 backward, and when the T-shaped slide block 14 moves out of the T-shaped groove 13, the rear splash guard 7 and the The machine tool body 4 is separated, thereby realizing the rapid assembly function of the present invention, which is convenient for operators to operate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com