Processing method of digital-analog printed circuit board

A technology for printed circuit boards and processing methods, applied in the directions of printed circuits, printed circuit manufacturing, multilayer circuit manufacturing, etc., can solve problems such as inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

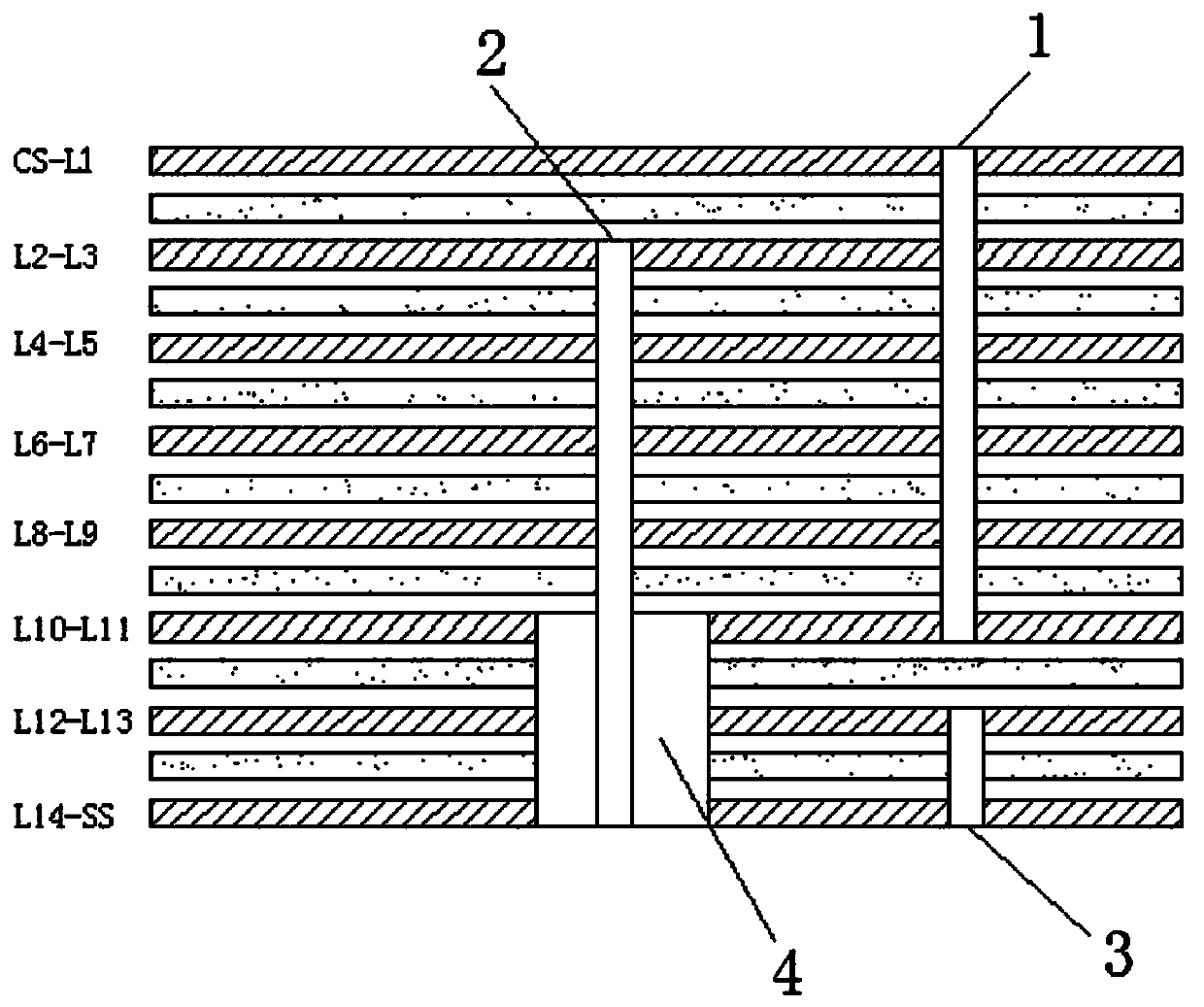

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] Neither the endpoints nor any values of the ranges disclosed herein are limited to such precise ranges or values, and these ranges or values are understood to include values approaching these ranges or values. For numerical ranges, between the endpoints of each range, between the endpoints of each range and individual point values, and between individual point values can be combined with each other to obtain one or more new numerical ranges, these values Ranges should be considered as specifically disclosed herein.

[0025] The invention provides a processing method of a digital-to-analog printed circuit board, the processing method comprising:

[0026] 1) Carry out material cutting, graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com