Method for using center calibration device of engine vibration experiment

一种中心校准、校准装置的技术,应用在发动机的测试、测量装置、位置/方向控制等方向,能够解决连接点位置同轴度不好准确判断、机体激烈震动、费时费力等问题,达到缩短实验准备时间、零件互换性强、灵活性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments.

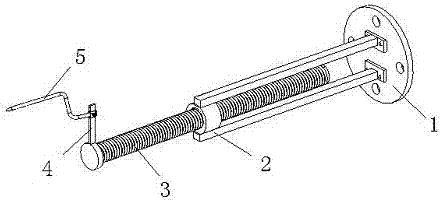

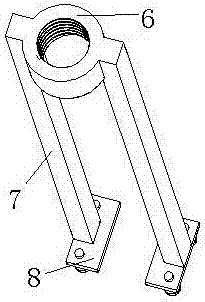

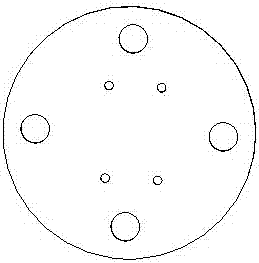

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a central calibration device for an engine vibration experiment includes a connection plate 1, and also includes a fixed bracket 2, a screw rod 3 and a detection needle 5 arranged in sequence. The bracket fixing holes are distributed in shape, and there are installation holes on the connecting plate away from the center; the fixing bracket is fixed on the connecting plate through nuts and bolts, which includes threaded sleeves 6, supporting arms 7 and fixing plates arranged in sequence from top to bottom 8. There are two support arms 7, both of which are symmetrically fixed on both sides of the threaded sleeve 6; there are two fixed plates 8, which are respectively fixed on the bottom of the support arms, and the fixed plate 8 is a rectangular structure, on which there are 2 screw holes; the layout of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com