Flute sound tube shaping and bundling machine

A flute tube and shaping block technology, which is applied in the field of flute tube shaping and forming balers, can solve the problems of unsightly bundling of flute tubes, high labor costs, and slow speed, and achieve manpower saving, gap reduction, and high speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing, the present invention is further elaborated.

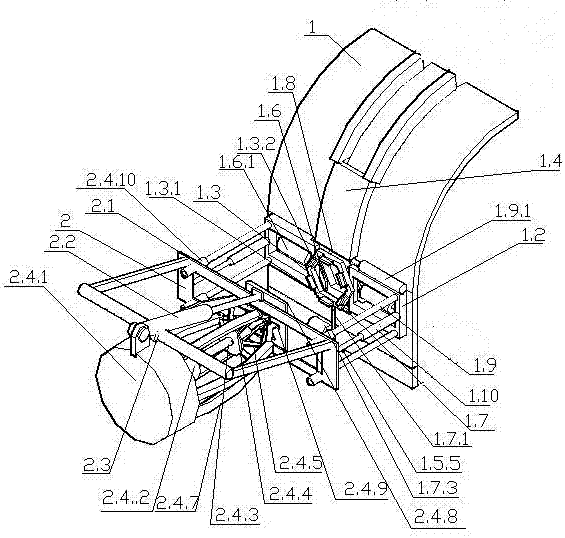

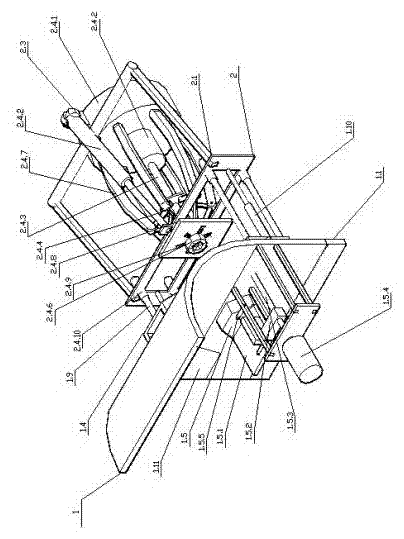

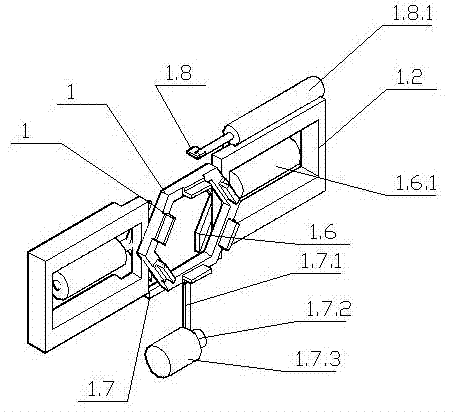

[0014] like Figure 1-2 As shown, the flute tube shaping and forming machine includes a shaping mechanism 1 and a binding mechanism 2, wherein the shaping mechanism 1 includes a bracket 1.1, a mold 1.3, a push plate 1.5, a shaping block 1.6, a baffle plate 1.7 and a sliding block 1.8, wherein The left and right sides of the front of the bracket 1.1 are fixed with two fixed brackets 1.2 arranged in parallel. It is hexagonal, and there are hexagonal mold holes on the shape mold 1.3, and six limit blocks 1.3.1 are fixed on the front of the shape mold 1.3, and the position of the limit blocks 1.3.1 is in line with the six sides of the shape mold 1.3. Corresponding; the bracket 1.1 at the rear of the shape die 1.3 has a hexagonal groove, and a hexagonal push plate 1.5 is embedded in the hexagonal groove, and the hexagonal groove fits with the push plate 1.5, and the hexagonal groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com