Straw forage harvesting and bundling integrated machine

An all-in-one machine and forage technology, which is applied in the direction of balers, harvesters, agricultural machinery and implements, etc., can solve the problems of unfavorable straw forage harvesting and baling, poor baling effect, and disorderly baling, etc. Bundle efficiency, reduce manual participation, and facilitate the effect of harvesting and bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

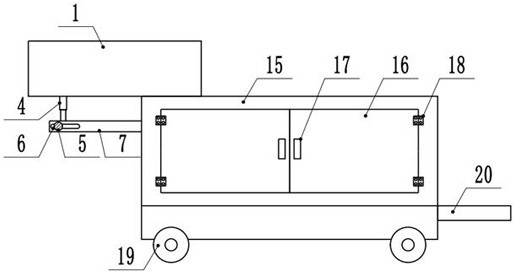

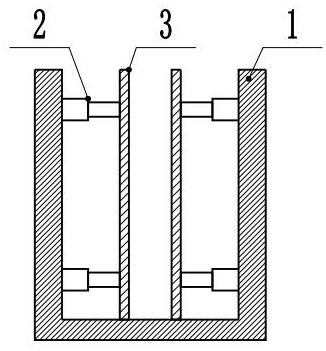

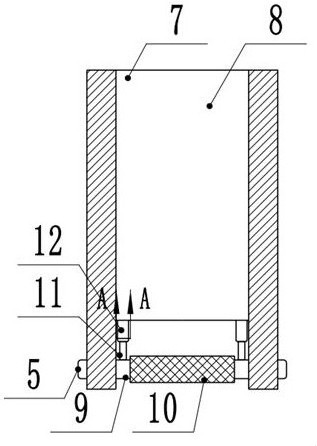

[0026] see Figure 1-6 , an all-in-one machine for straw and forage harvesting and bundling, comprising a bundling box 15, an auxiliary fixing box 1 is fixedly connected to the left side of the upper surface of the bundling box 15, and an electric push rod 24 is fixedly installed on the lower surface of the auxiliary fixing box 1, and the electric pusher The bar two 4 other ends are fixedly connected with the harvesting box 7, and the casing on the left side of the bundling box 15 is provided with a vertically elongated opening, and the harvesting box 7 right-hand ends stretch into the elongated opening.

[0027] In addition, a partition 23 is fixedly connected to the bottom of the left and right sides of the bundling box 15, and a bearing 25 is fixedly installed inside the middle of the partition 23, and a vertical rotating rod 24 is fixedly connected inside the middle of the bearing 25, and the rotating rod 24 The lower end is rotatably equipped with a motor 22, and the rota...

Embodiment 2

[0031] see Figure 1-6 , an all-in-one machine for straw and forage harvesting and bundling, comprising a bundling box 15, an auxiliary fixing box 1 is fixedly connected to the left side of the upper surface of the bundling box 15, and an electric push rod 24 is fixedly installed on the lower surface of the auxiliary fixing box 1, and the electric pusher The bar two 4 other ends are fixedly connected with the harvesting box 7, and the casing on the left side of the bundling box 15 is provided with a vertically elongated opening, and the harvesting box 7 right-hand ends stretch into the elongated opening.

[0032] In addition, a partition 23 is fixedly connected to the bottom of the left and right sides of the bundling box 15, and a bearing 25 is fixedly installed inside the middle of the partition 23, and a vertical rotating rod 24 is fixedly connected inside the middle of the bearing 25, and the rotating rod 24 The lower end is rotatably equipped with a motor 22, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com