Guide Carriage with a Sensory Layer on the Raceway Insert

A rolling surface and sensing layer technology, applied in linear motion bearings, rotating parts that resist centrifugal force, bearings, etc., can solve problems such as reducing the measurement accuracy of sensors, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

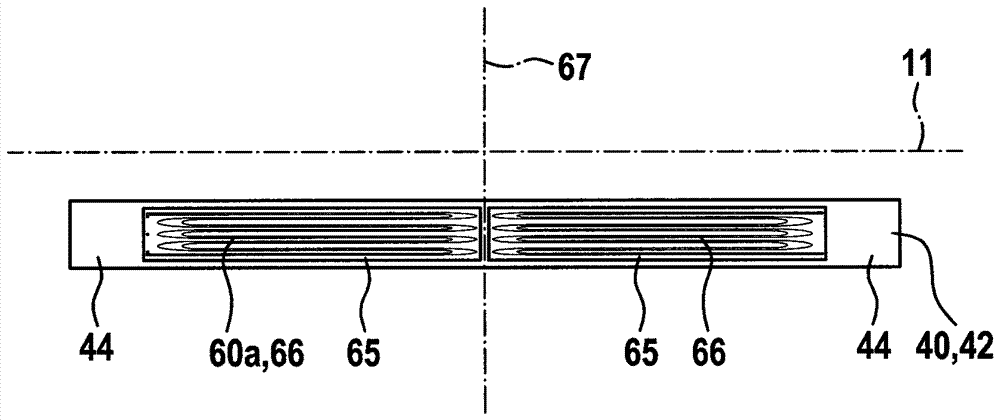

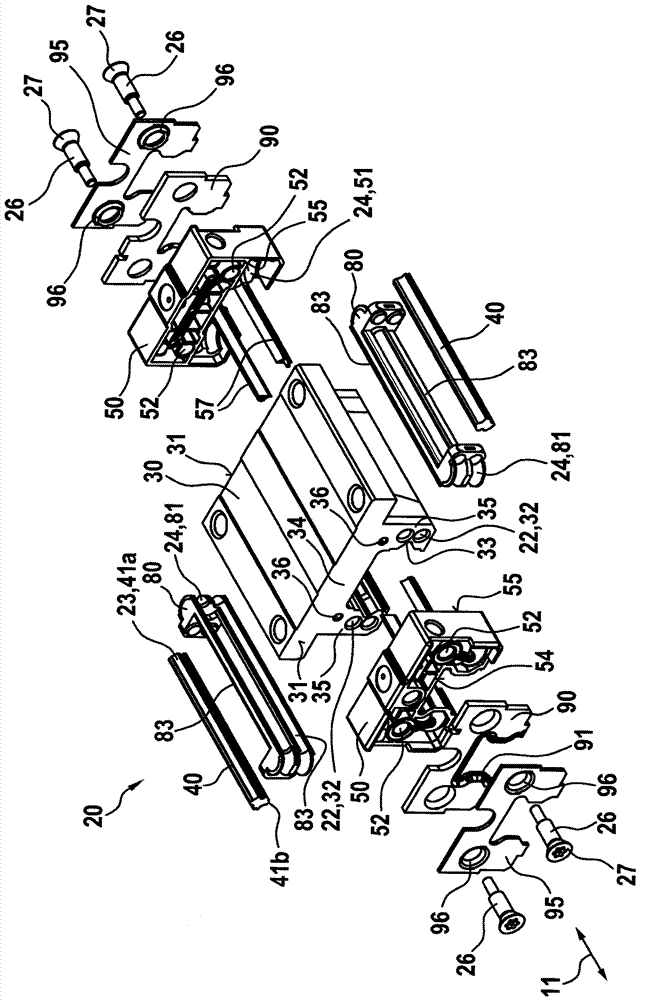

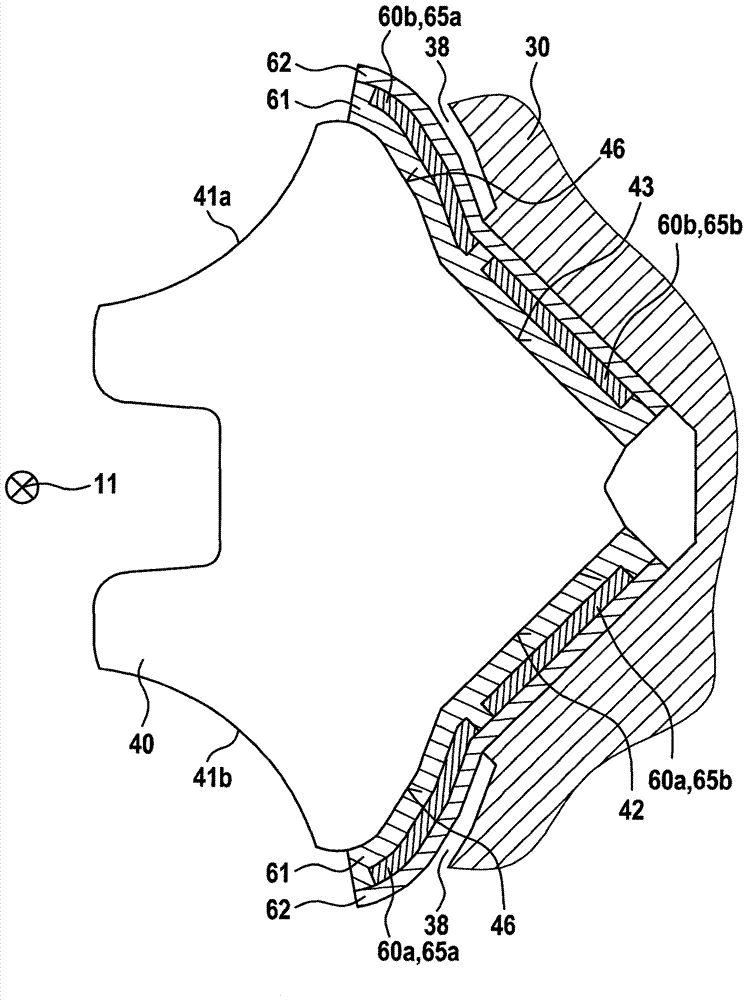

[0088] figure 1 An exploded view of the guide carriage 20 according to the invention is shown. Said guide carriage 20 comprises a body 30 made of non-hardened steel extending along the longitudinal axis 11 with a substantially constant U-shaped cross-section. V-shaped grooves 33 are respectively arranged on the inner sides of the U-legs 35 , against which grooves a separate running surface pad 40 , which is made of hardened rolling bearing steel, rests in each case. Two running surface pads 40 extend along the longitudinal axis 11 with a substantially constant cross section, wherein they each have two carriage running surfaces 41a, 41b, so that the guide carriage 20 has a total of four rows of spherical rolling bodies ( figure 2 Reference number 21 in ).

[0089] An end cap 50 with an inner longitudinal end face 55 is in direct contact with each of two opposite flat longitudinal end faces 31 of the main body 20 . The two end caps 50 are constructed identically, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com