A preparation method of density-controllable profiling rotator

A technology of revolution and density, which is applied in the direction of textiles and papermaking, needle punching machines, non-woven fabrics, etc., can solve the problems that the density cannot be adjusted, etc., achieve good interlayer bonding strength, high profiling accuracy, and improve profiling sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of carbon fiber rotary fabric, thick at both ends and thin in the middle, the outer diameter of the large end (both ends) is Ф350 mm, the inner diameter of the large end is Ф310 mm, the diameter of the throat (the smallest diameter in the middle) is Ф100 mm, and the height (rotary body axis To length) is 220mm. The design unit layer uses a layer of 3K twill carbon cloth + a layer of fiber mesh tire + a layer of 12K carbon cloth reinforcement layer to form a unit layer. The preparation steps are as follows:

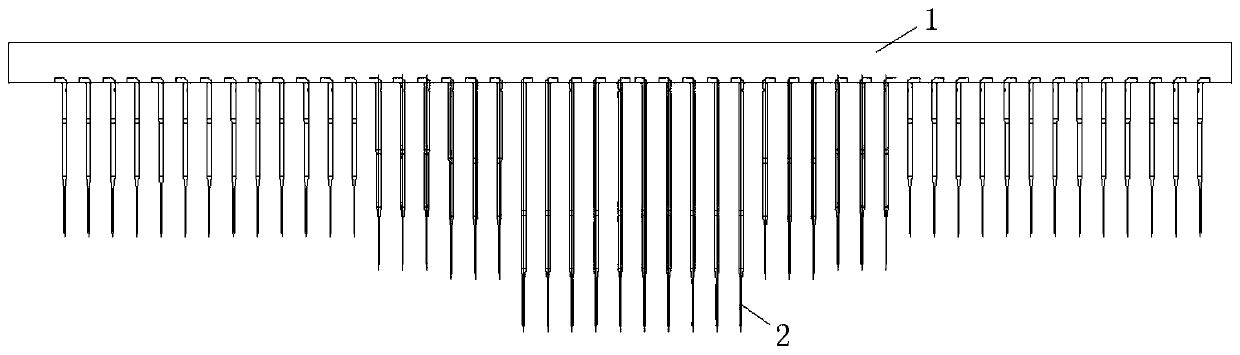

[0047] ⑴According to the shape characteristics of the fabric, take the minimum throat diameter of the carbon fiber rotary fabric as the dividing point, and divide it into two parts: left and right. Arranged from left to right, the lengths are 80 2.5-inch needles, 50 3.0-inch needles, and 80 3.5-inch needles. , 50 3.0-inch felting needles, 80 2.5-inch felting needles, the arrangement of the needles adapts to the change of the product busbar, an...

Embodiment 2

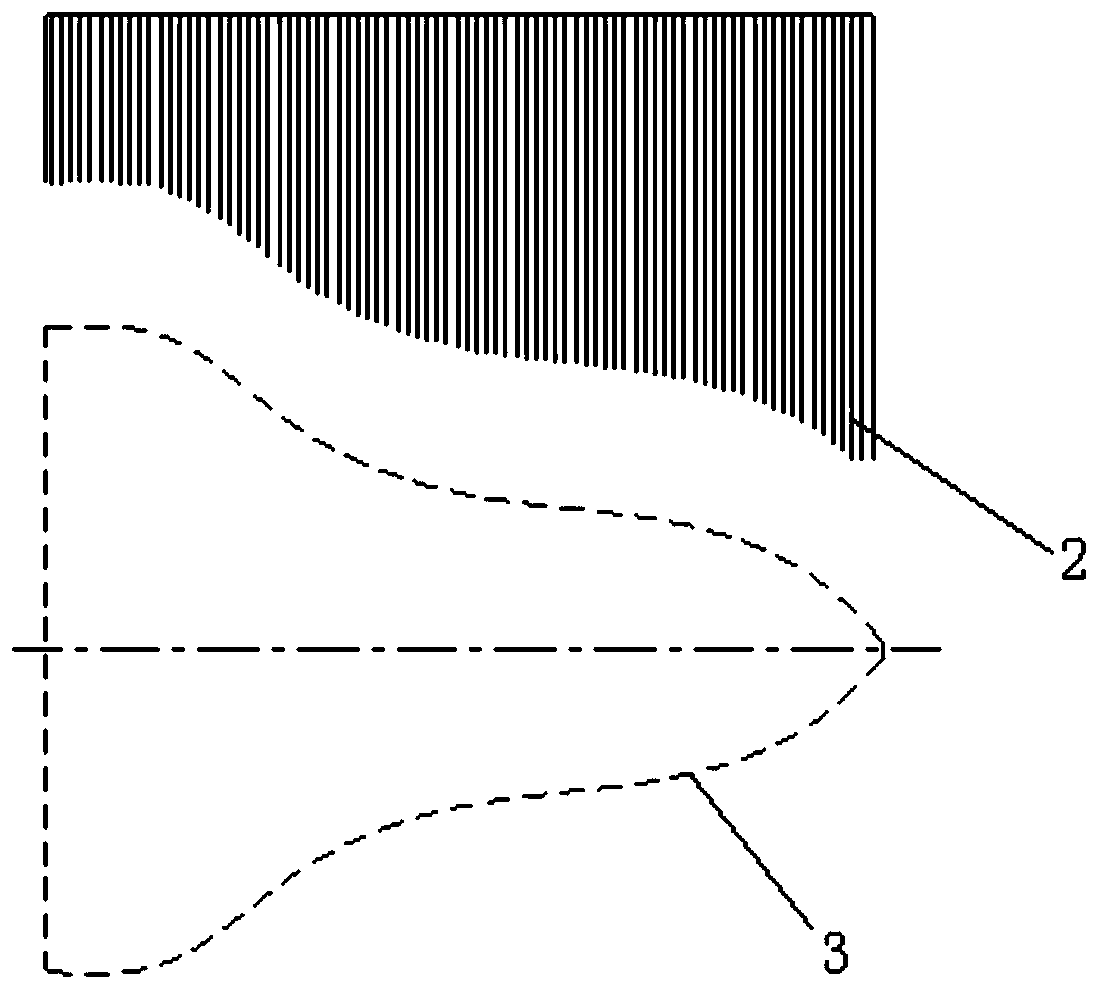

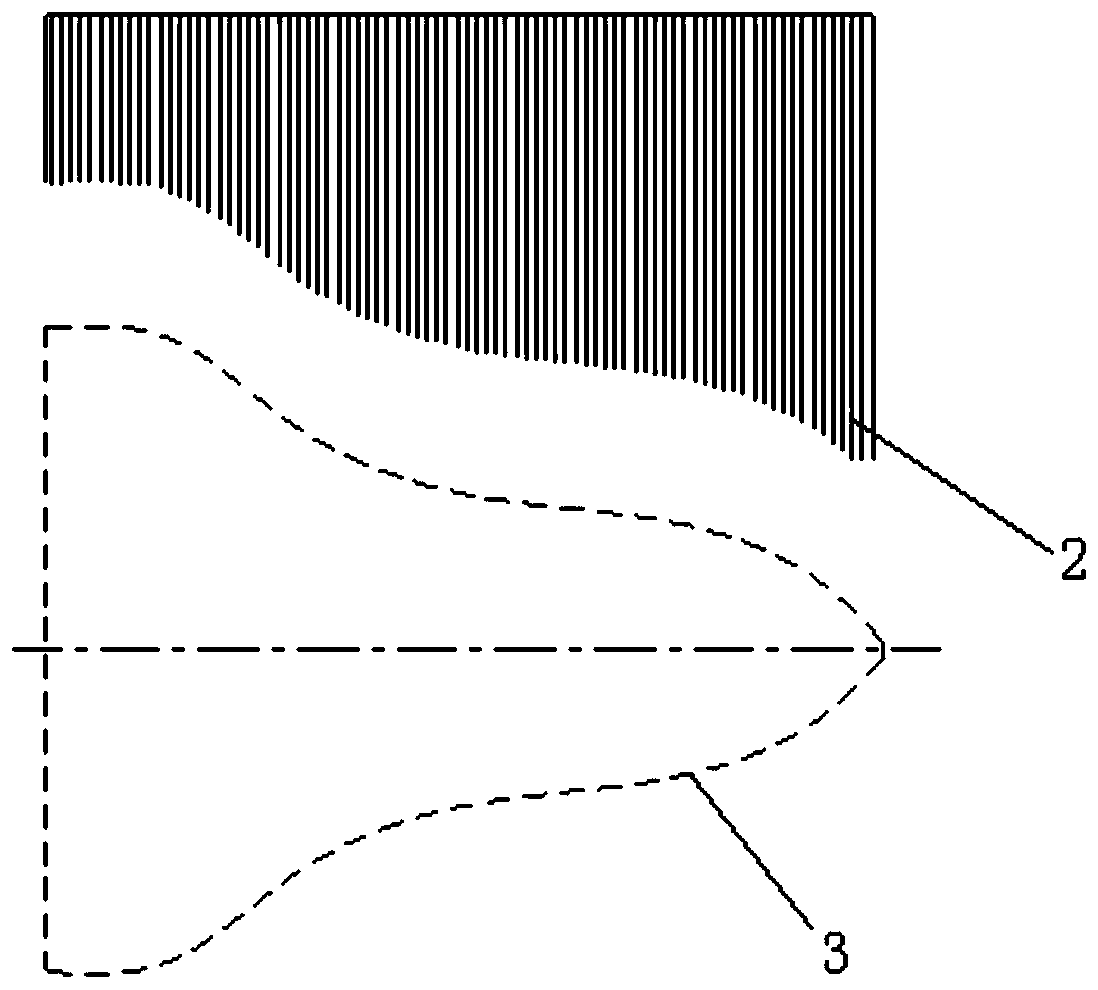

[0056] Embodiment 2: as figure 2 As shown, the quartz fiber cone fabric is prepared: the shape is cone-shaped, the outer diameter of the big end is Ф500 mm, the inner diameter of the big end is Ф460 mm, and the height (axial length) is 600 mm. The design unit layer adopts a layer of quartz fiber mesh tire + a layer of quartz fiber satin cloth to form a unit layer. The preparation steps are as follows:

[0057] ⑴According to the shape characteristics of the tapered fabric, in the transition area from the big end to the top of the product, 80 2.5-inch needles, 60 3.0-inch needles, and 40 3.5-inch needles are arranged in sequence. Approximate profiling;

[0058] (2) Apply hot melt adhesive on the surface of the prepared cone mold, and at the same time, cut the chemical fiber felt material with a thickness of 15mm (the weight is 2500g / m 2 ) is in the form of a strip, wound from the small end of the mold to the large end until the package is firmly pasted;

[0059] ⑶ Add 120g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com