System provided with long belt replacement mechanism and replacement method

A technology for belts to be replaced, applied in conveyors, transportation and packaging, etc., can solve the problems of long belt replacement time affecting output and construction period, waste of manpower and material resources, etc., to achieve simple installation, easy construction work, and save construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

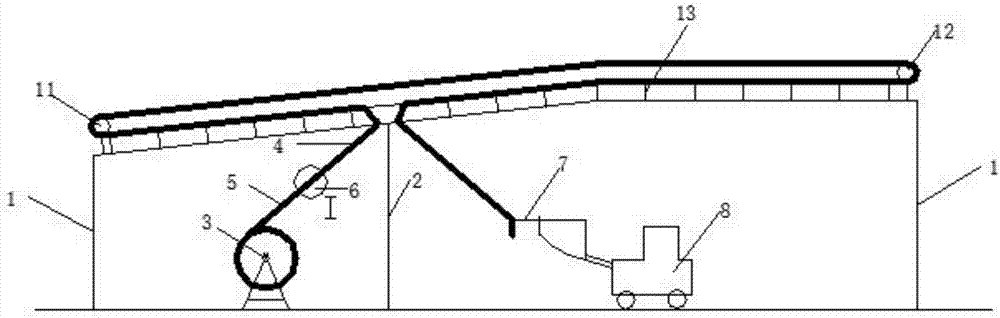

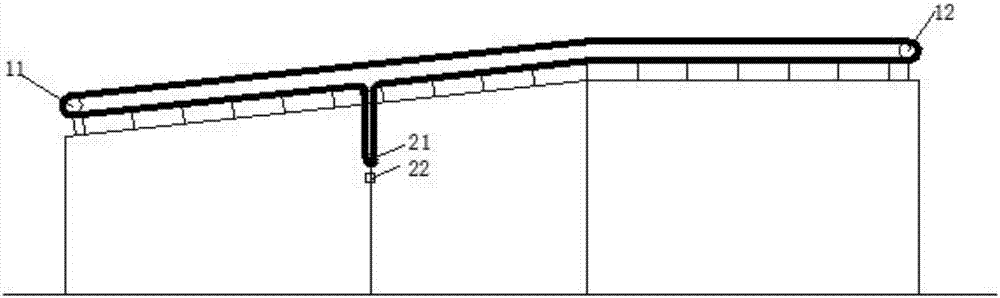

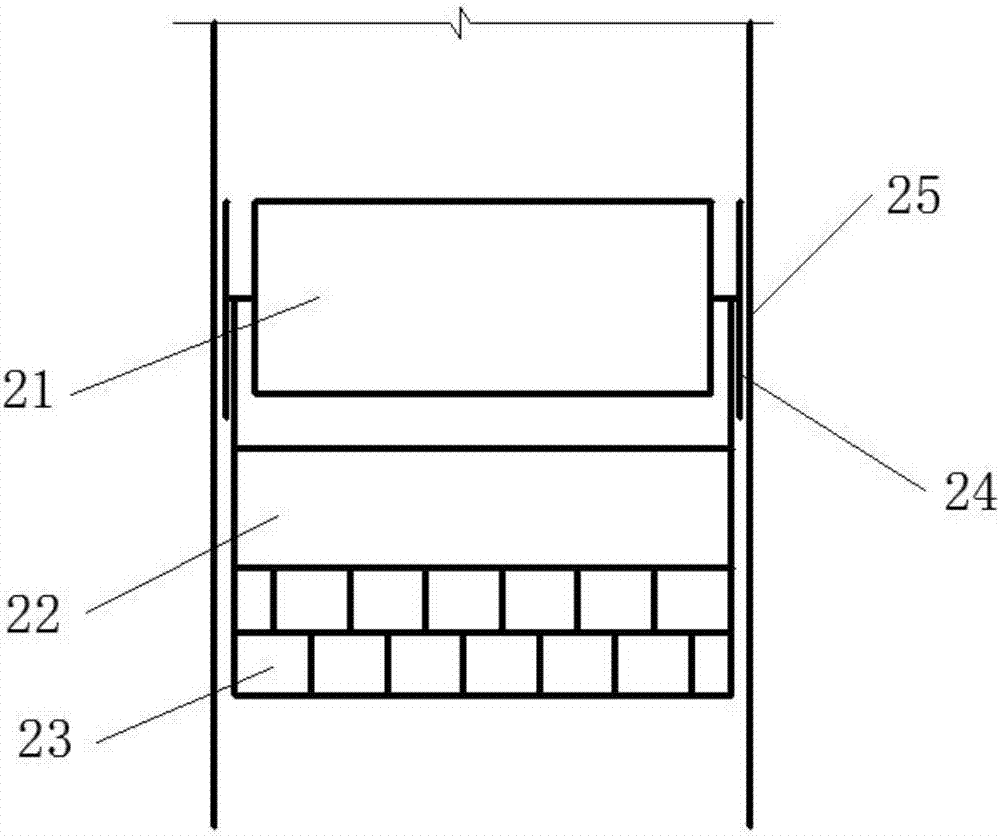

[0045] Such as figure 1 and figure 2 As shown, this example is a system with a belt replacement mechanism, including a transmission mechanism, a tension mechanism 2 and a replacement mechanism, wherein a transmission belt is set on the transmission mechanism for transporting materials, and the transmission mechanism includes a bracket 1, a head roller 12 and the tail drum 11, the head drum 12 and the tail drum 11 are respectively arranged at the two ends of the support 1, and the head drum 12 and the tail drum 11 are equipped with long belts to ensure that the belt runs smoothly and facilitates belt transmission. The belt is set on the head drum 12 and the tail drum 11, and the belt is divided into upper and lower parts. The idler roller 13 is arranged under the belt, the upper idler roller is arranged under the upper part of the belt, and the lower idler roller is arranged under the lower part of the belt. structured as Figure 5 As shown, the upper idler includes an idler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com