Plastic particle storing tank with distribution device

A technology of diverting device and plastic granules, applied in the direction of conveying bulk materials, packaging, transportation and packaging, etc., can solve the problems of long manual cleaning time, high labor intensity of workers, general cleaning effect, etc., so as to save cleaning work and have a simple structure. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

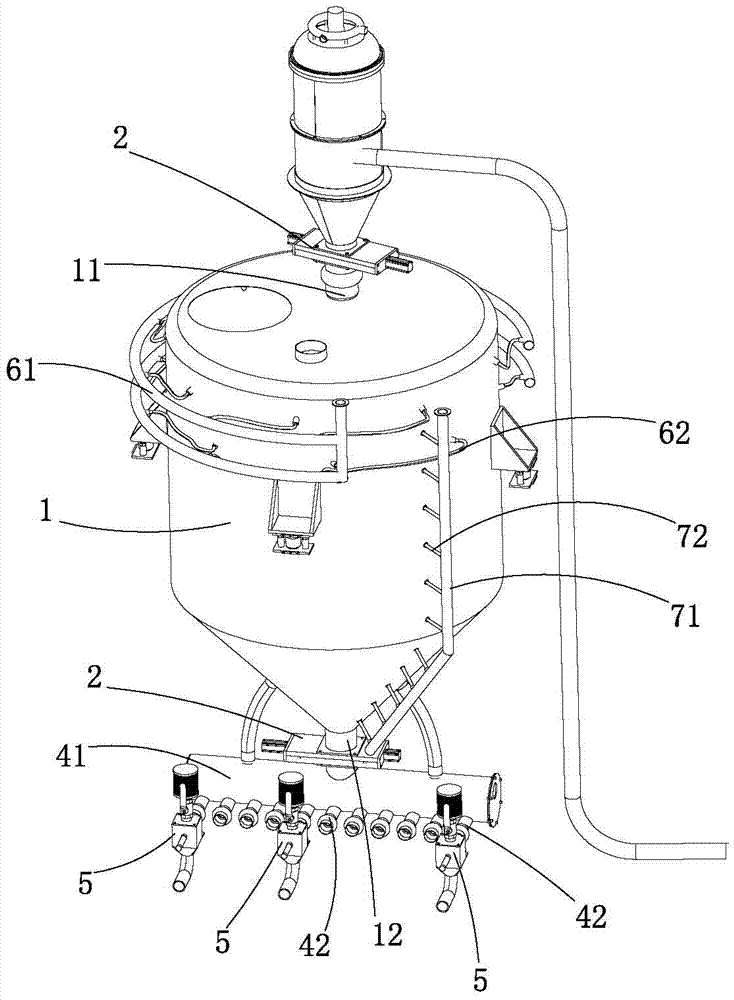

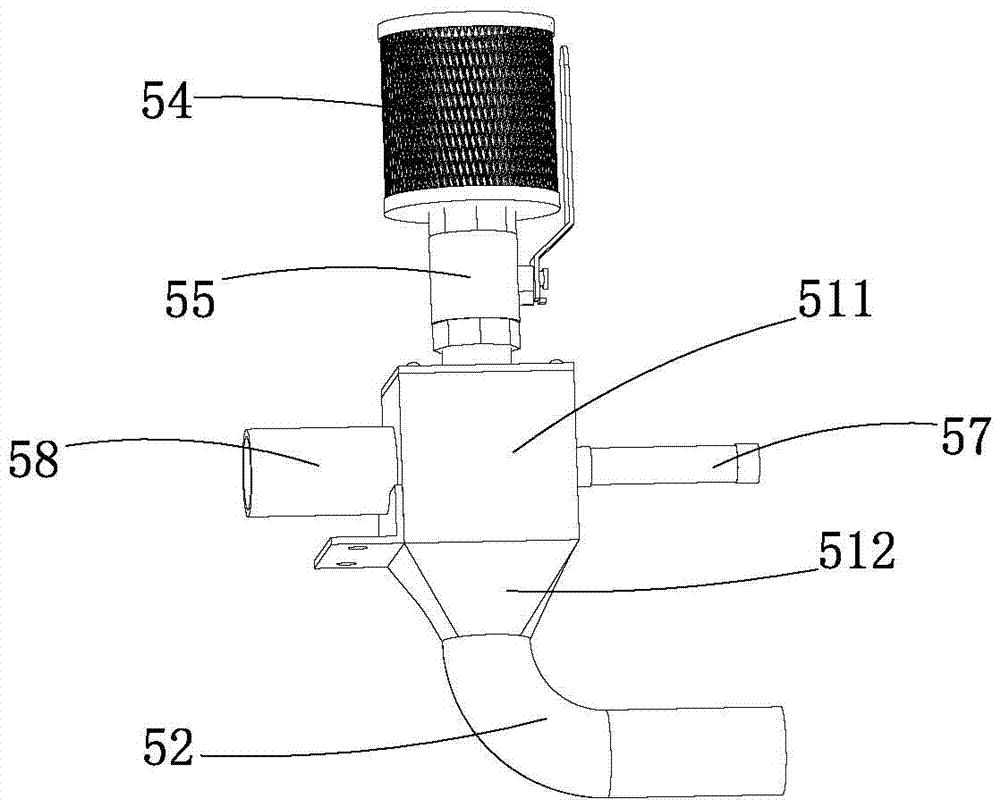

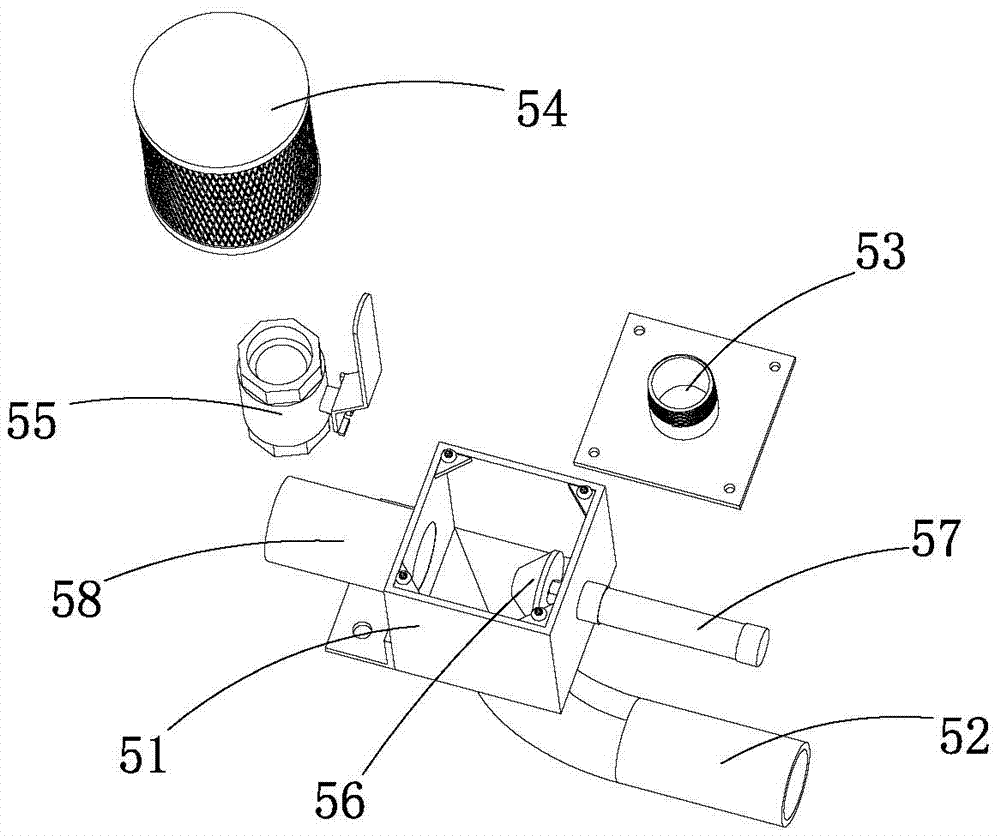

[0025] see Figure 1 to Figure 3 , according to the embodiment of the plastic granule storage tank with a diversion device provided in the present invention, comprising a tank body 1, a cleaning mechanism arranged on the tank body 1 and a diversion device connected to the tank body 1, the tank The body 1 is provided with a feed port 11 and a discharge port 12, and the flow diversion device is connected with the discharge port 12. A plurality of branch branch pipes 42 connected by the main pipe 41, a plurality of branch branch pipes 42 are provided with a material valve 5 with a ventilation channel, and the material valve 5 includes a valve box 51, a valve box located on the side wall of the valve box Feed pipe 58, the discharge pipe 52 that is located at the bottom of the valve box 51, the air inlet 53 that is located at the top of the valve box 51, the valve plug 56 that is located in the valve box 51 and is connected with the valve The handle 57 connected to the plug 56, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com