Cleaning device for insulating paint for auxiliary transformer iron core

A technology of auxiliary transformer and cleaning device, which is applied to grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of waste of resources, low practicality of cleaning equipment, and difficulty in cleaning insulating paint collection, etc. collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

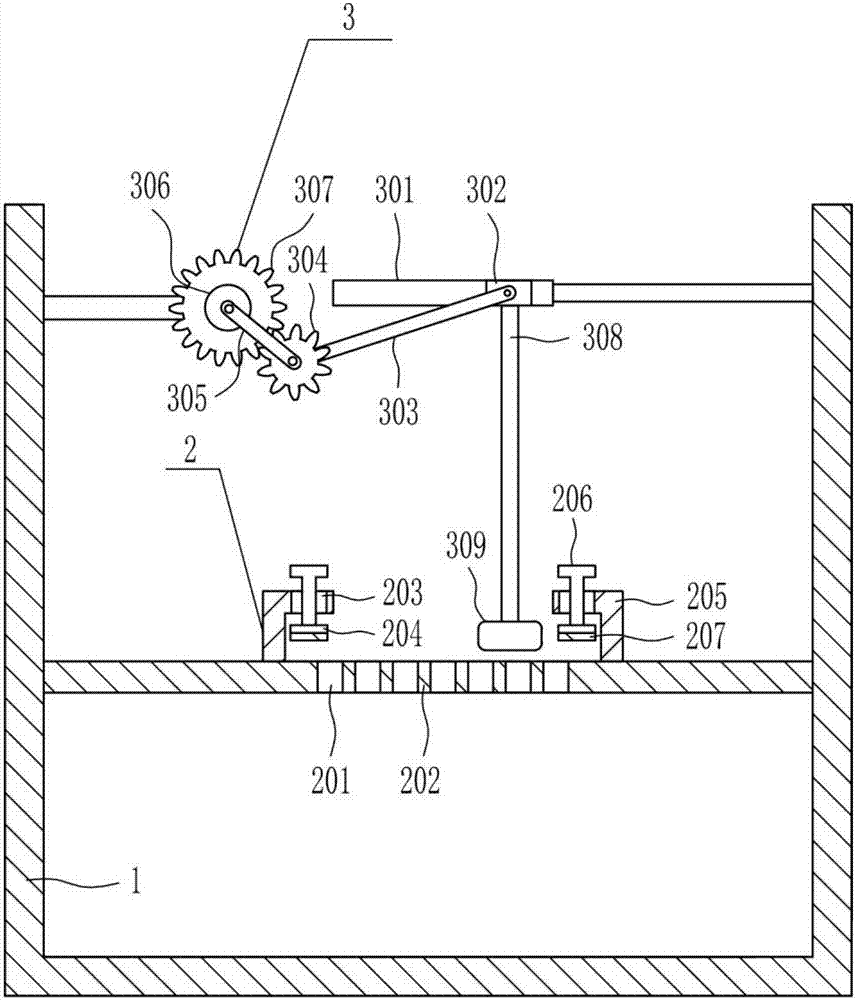

[0032] A device for removing insulating varnish for auxiliary transformer iron core, such as Figure 1-5 As shown, it includes a frame 1, a fixing mechanism 2 and a clearing mechanism 3, the upper part of the top of the frame 1 is connected with a clearing mechanism 3, and the middle part of the frame 1 is connected with a fixing mechanism 2.

Embodiment 2

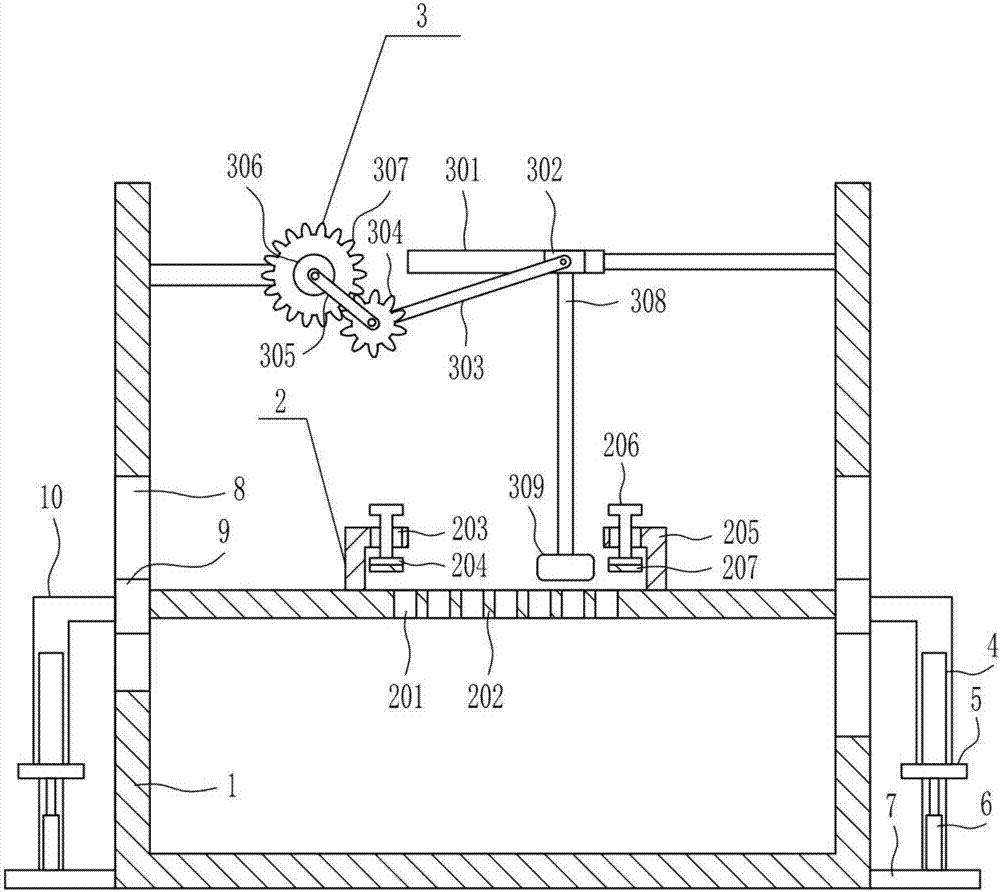

[0034] A device for removing insulating varnish for auxiliary transformer iron core, such as Figure 1-5 As shown, it includes a frame 1, a fixing mechanism 2 and a clearing mechanism 3, the upper part of the top of the frame 1 is connected with a clearing mechanism 3, and the middle part of the frame 1 is connected with a fixing mechanism 2.

[0035] The fixing mechanism 2 includes a placing plate 202, a pressing block 204, a fixing rod 205, a bolt 206 and a first rubber pad 207. The middle part of the frame 1 is connected with the placing plate 202, and the middle part of the placing plate 202 is evenly opened with a first through hole 201. The top of the placement plate 202 is symmetrically connected with fixed rods 205. The fixed rods 205 are all provided with first threaded holes 203. The first threaded holes 203 are connected with bolts 206 by means of threaded connections. The bottom ends of the bolts 206 are connected with pressure The block 204 and the bottom of the p...

Embodiment 3

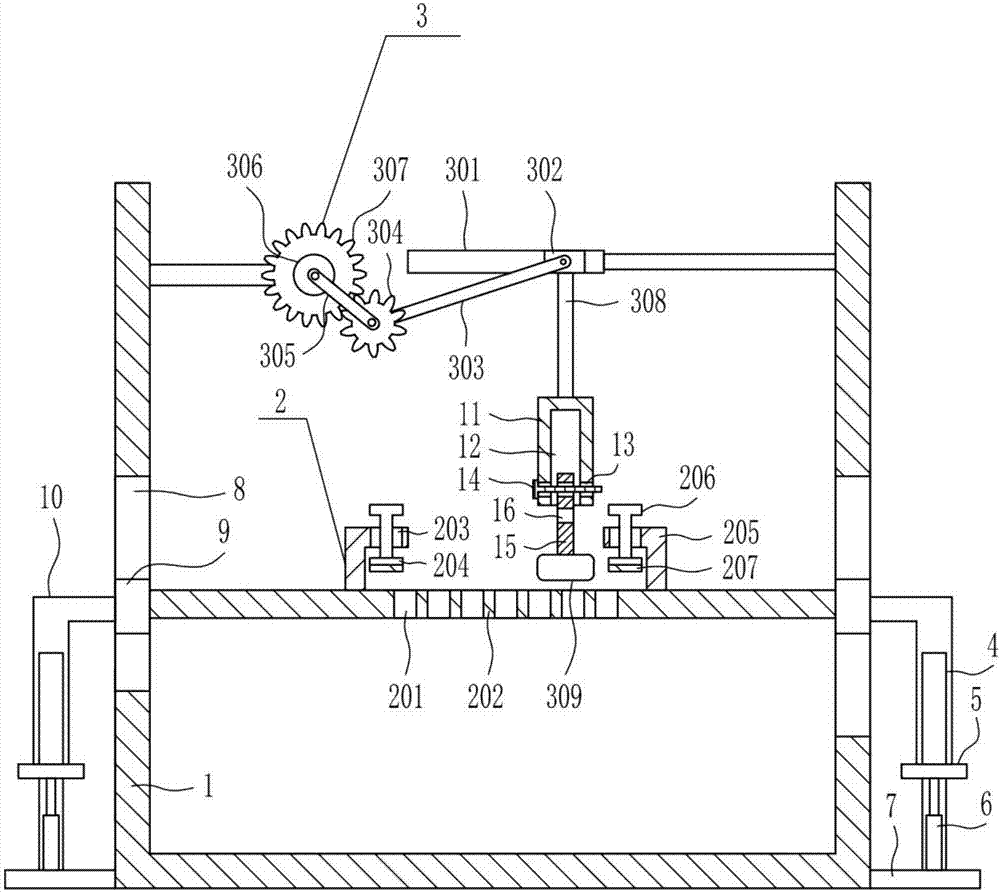

[0037] A device for removing insulating varnish for auxiliary transformer iron core, such as Figure 1-5 As shown, it includes a frame 1, a fixing mechanism 2 and a clearing mechanism 3, the upper part of the top of the frame 1 is connected with a clearing mechanism 3, and the middle part of the frame 1 is connected with a fixing mechanism 2.

[0038] The fixing mechanism 2 includes a placing plate 202, a pressing block 204, a fixing rod 205, a bolt 206 and a first rubber pad 207. The middle part of the frame 1 is connected with the placing plate 202, and the middle part of the placing plate 202 is evenly opened with a first through hole 201. The top of the placement plate 202 is symmetrically connected with fixed rods 205. The fixed rods 205 are all provided with first threaded holes 203. The first threaded holes 203 are connected with bolts 206 by means of threaded connections. The bottom ends of the bolts 206 are connected with pressure The block 204 and the bottom of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com