Faucet hole drilling machining equipment

A processing equipment and faucet technology, applied in metal processing equipment, drilling/drilling equipment, boring/drilling, etc., can solve the problems of inflexible use, high cost of use, and low processing accuracy, and achieve convenient and fast positioning , high production efficiency and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

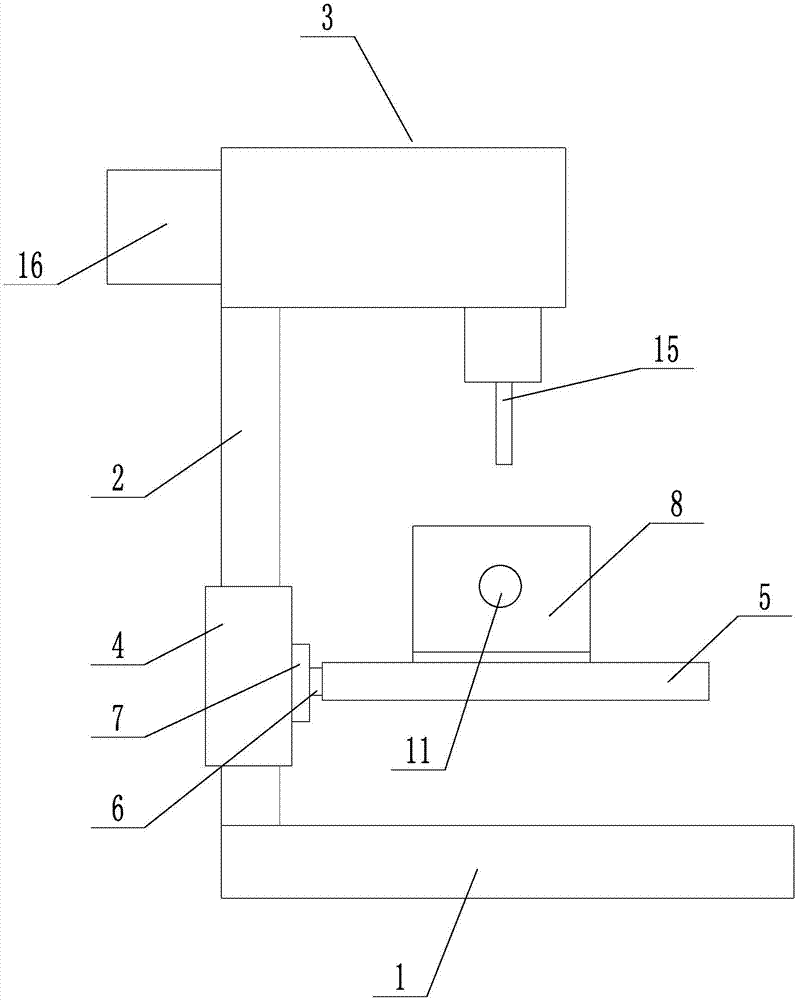

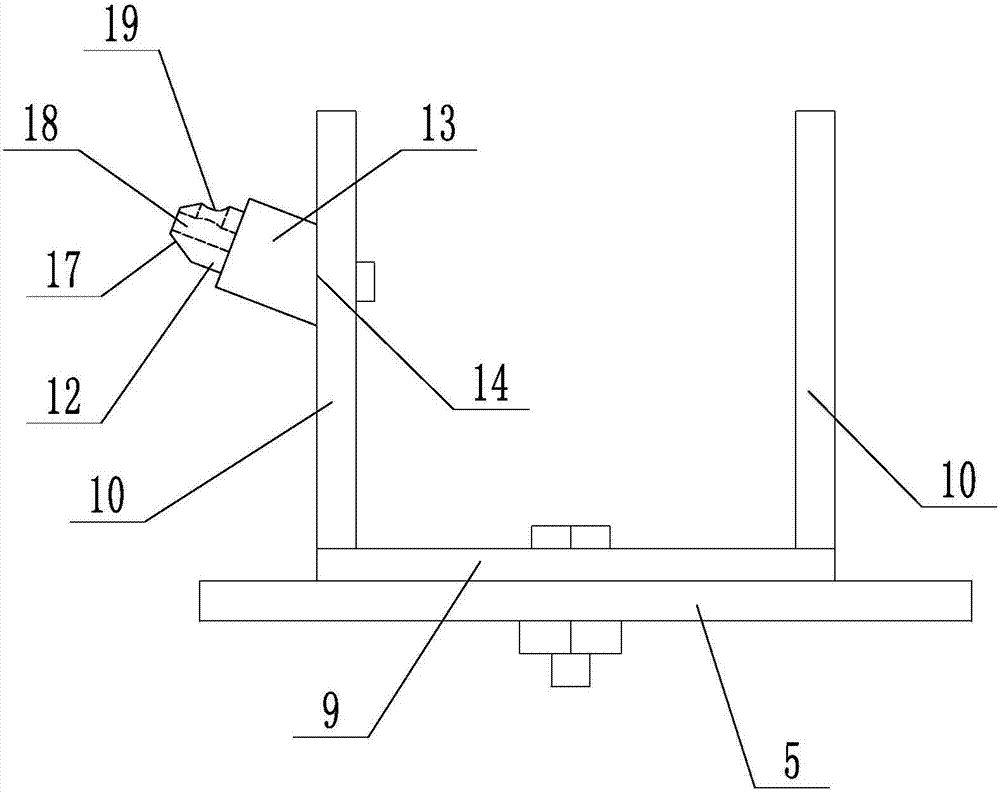

[0014] Such as figure 1 and figure 2 As shown, a faucet drilling processing equipment includes a base 1, a support column 2 is vertically provided on the base 1, a drilling mechanism 3 is provided on the top of the support column 2, and a rotation adjustment mechanism is provided in the middle of the support shaft, namely The rotation adjustment mechanism is arranged below the drilling mechanism 3. The rotation adjustment mechanism includes a rotation block 4 and a support plate 5. The rotation block 4 is in the shape of a sleeve arranged in a column shape. The rotation block 4 is set on the support column 2 and rotates with the support column 2. Cooperate, the edge of support plate 5 is provided with rotating shaft 6, and rotating block 4 is provided with the connecting part 7 that is rotatably matched with rotating shaft 6, and connecting part 7 is that rotating block 4 is provided with protrusion, and protrusion is provided with shaft hole, and rotating shaft 6 is rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com