Alloy three-layer structure surface groove control method

A technology of three-layer structure and control method, which is applied in the field of surface groove defect control of superplastic formed three-layer structural parts for aerospace. Groove defects etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

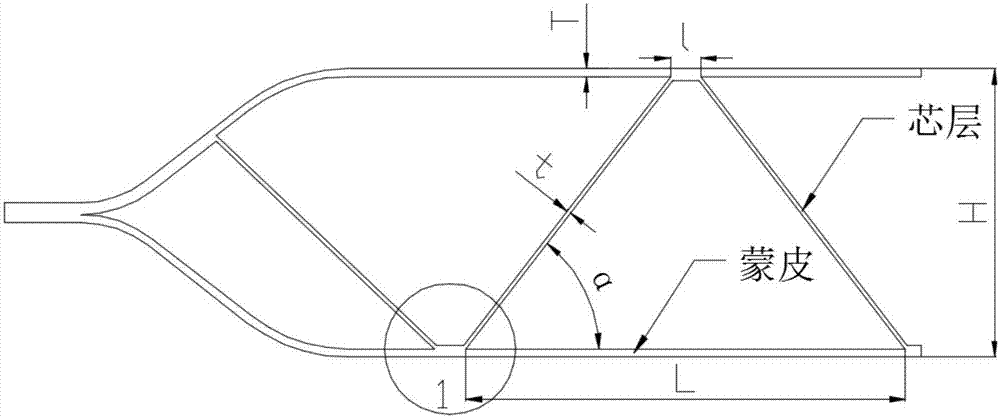

[0095] A kind of Ti 2 AlNb alloy laser welding / superplastic forming three-layer structure surface groove control method, such as figure 1 As shown, the three-layer structure is a sandwich structure consisting of a core layer and skins on both sides of the core layer. Solder connection;

[0096] The steps of the method include:

[0097] (1) For Ti 2 AlNb alloy is used for material selection, the thickness of the selected skin is T=2mm, and the thickness of the core layer is t=1mm;

[0098] (2) Laser welding the core layer and the skin;

[0099] Such as Figure 4 As shown, when welding, use 3 parallel laser welds at the same welding position, and the shortest distance between adjacent welding positions on the same side is L=50mm, H=40mm, l=6mm;

[0100] (3) superplastic molding is carried out to the core layer and skin after step (2) laser welding;

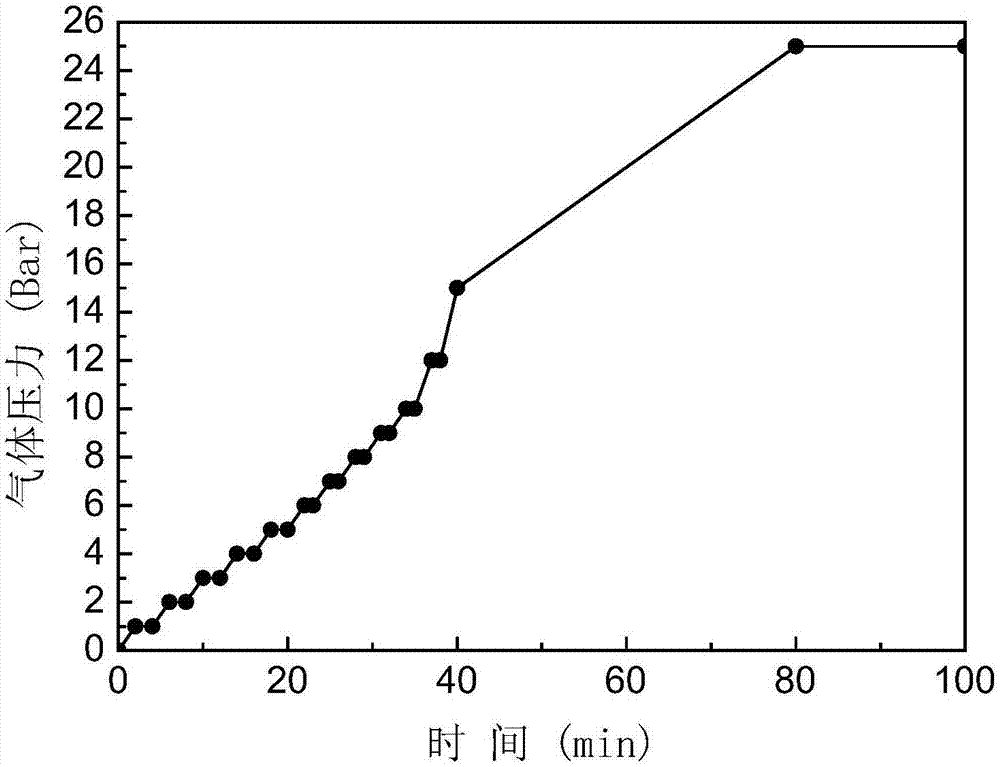

[0101] The superplastic forming temperature is 960°C, the superplastic forming pressure is P=25Bar, and the superplastic fo...

Embodiment 2

[0104] A kind of Ti 2 AlNb alloy laser welding / superplastic forming three-layer structure surface groove control method, such as figure 1 As shown, the three-layer structure is a sandwich structure consisting of a core layer and skins on both sides of the core layer. Solder connection;

[0105] The steps of the method include:

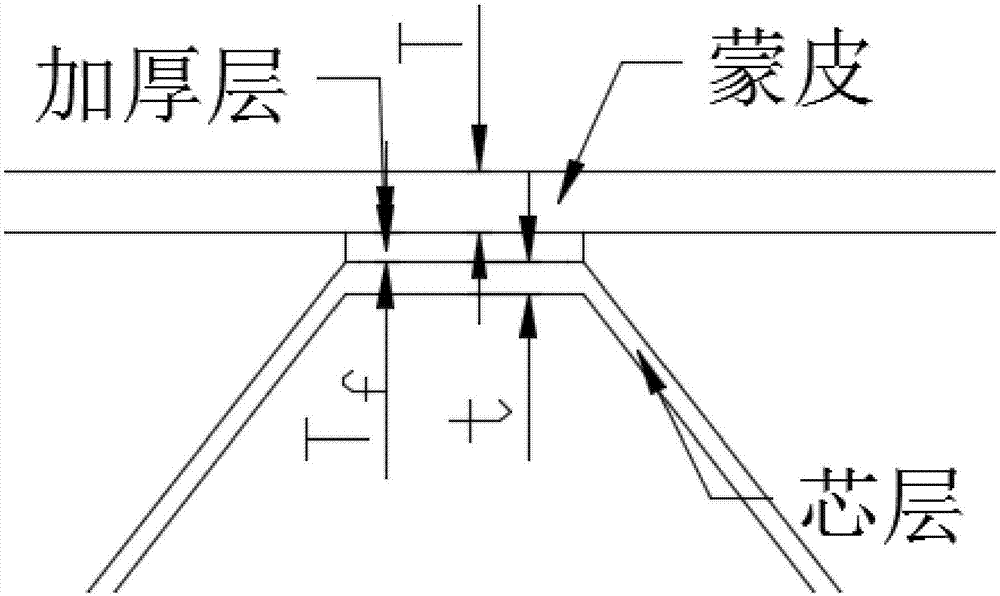

[0106] (1) For Ti 2 AlNb alloy is selected, the thickness of the selected skin is T=1mm, the thickness of the core layer is t=1mm; add auxiliary materials on the skin, the thickness of the auxiliary materials is T f = 1 mm;

[0107] (2) Laser welding the auxiliary material and the skin, as well as the auxiliary material and the core layer;

[0108] Such as Figure 4 As shown, when welding, use 3 parallel laser welds at the same welding position, and the shortest distance between adjacent welding positions on the same side is L=50mm, H=40mm, l=6mm;

[0109] (3) Carry out superplastic molding to the core layer, skin and accessories after step (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com