Oil-water separation device

A technology of oil-water separation device and separation box, which is applied in the direction of filtration separation, liquid separation, separation method, etc., which can solve the problems of long oil-water separation time and waste of labor, and achieve the effect of fast and thorough separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

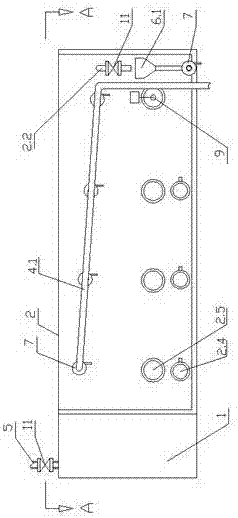

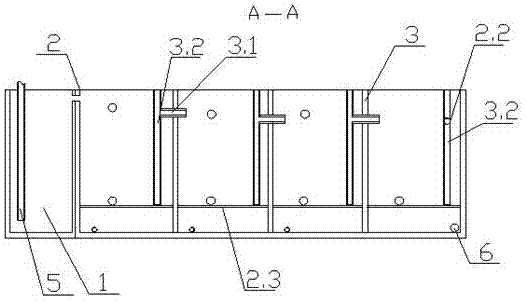

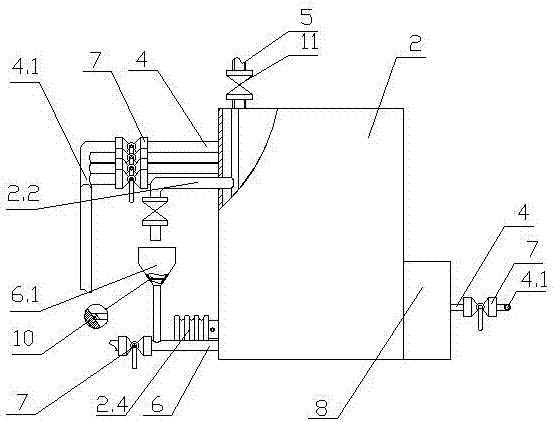

[0012] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0013] Such as Figure 1-4 As shown, the oil-water separation device includes a filter residue tank 1, a separation box 2, a partition plate 3, and an oil guide pipe 4. A feed pipe 5 is inserted in the filter residue tank 1, and the mouth of the feed pipe 5 is close to the bottom of the filter residue tank 1. 1 is welded with the separation box 2, and there is a rectangular groove on the bonding surface of the filter residue pool 1 and the separation box 2, and the rectangular groove connects the filter residue pool 1 and the separation box 2; three partitions 3 are arranged at equal intervals in the separation box 2, and the partitions 3 is welded to the front, rear and bottom surfaces of the separation box 2, the top surface of the partition 3 is flush with the top surface of the separation box 2, and the partition 3 divides the separation box 2 into four independent sedimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com