Biological deodorization technique for fish dissolved pulp

A technology for dissolving fish paste and removing fishy smell, which is applied in the direction of food science, etc., can solve the problems of unsatisfactory fishy smell removal effect and cumbersome operation of the fishy smell removal method, and achieve good fishy smell removal effect, excellent adsorption and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

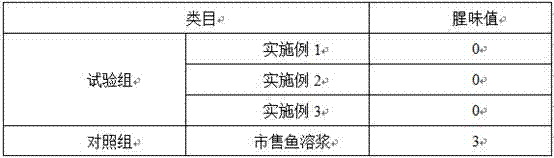

Examples

Embodiment 1

[0014] A biological deodorization technology for fish soluble pulp, including deaminization by urease, deodorization by fermentation, decolorization and deodorization by activated carbon. The deodorization of fermentation is to add aroma yeast and its fermentation liquid to the fish soluble slurry for incubation, the fermentation temperature is 30°C, the fermentation time is 35h, and the fermentation is sealed. The incubation temperature was 35°C and the incubation time was 6h. Aroma-producing yeast can ferment and decompose fishy substances, and use them as a nitrogen source to provide energy for its own metabolism; the fermentation product ethanol also has the effect of deodorizing, reducing the fishy smell of fish paste.

[0015] Urease deamination is to add urease enzymatic hydrolysis to the fish soluble pulp, the amount of enzyme added is 0.05% w / v of the fish soluble pulp, the pH is 5.8, the temperature is 35°C, and the enzymatic hydrolysis time is 48 minutes. Urease ca...

Embodiment 2

[0019] A biological deodorization technology for fish soluble pulp, including deaminization by urease, deodorization by fermentation, decolorization and deodorization by activated carbon. The deodorization of fermentation is to add aroma yeast and its fermentation liquid to the fish soluble slurry for incubation, the fermentation temperature is 30°C, the fermentation time is 35h, and the fermentation is sealed. The incubation temperature was 35°C and the incubation time was 6h. Aroma-producing yeast can ferment and decompose fishy substances, and use them as a nitrogen source to provide energy for its own metabolism; the fermentation product ethanol also has the effect of deodorizing, reducing the fishy smell of fish paste.

[0020] Urease deamination is to add urease enzymatic hydrolysis to the fish soluble pulp, the amount of enzyme added is 0.04% w / v of the fish soluble pulp, the pH is 5.8, the temperature is 35°C, and the enzymatic hydrolysis time is 45 minutes. Urease ca...

Embodiment 3

[0024] A biological deodorization technology for fish soluble pulp, including deaminization by urease, deodorization by fermentation, decolorization and deodorization by activated carbon.

[0025] 1) Add 5 times of water to the fish-soluble slurry, stir evenly, add urease for enzymatic hydrolysis, the amount of enzyme added is 0.05% w / v of the fish-soluble slurry, the pH is 5.8, the temperature is 35°C, and the enzymatic hydrolysis time is 40 minutes. Urease can effectively enzymatically hydrolyze fishy substances and decompose them into small molecular substances without fishy smell. The reaction conditions are mild and will not destroy the active components in fish soluble pulp, and will not limit the application range of fish soluble pulp after deodorization. After enzymatic hydrolysis, use a boiling water bath for 6 minutes to inactivate the enzyme, filter, and take the filtrate;

[0026] 2) Add fermentation medium and aromatic yeast into the fermenter, seal it for ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com