Ultrasonic A scanning signal based defect three-dimensional reconstruction method

A three-dimensional reconstruction and defect technology, which is applied in processing the response signal of detection, using sonic/ultrasonic/infrasound for material analysis, measuring devices, etc., which can solve the problems of low automation and low scanning efficiency of ultrasonic nondestructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

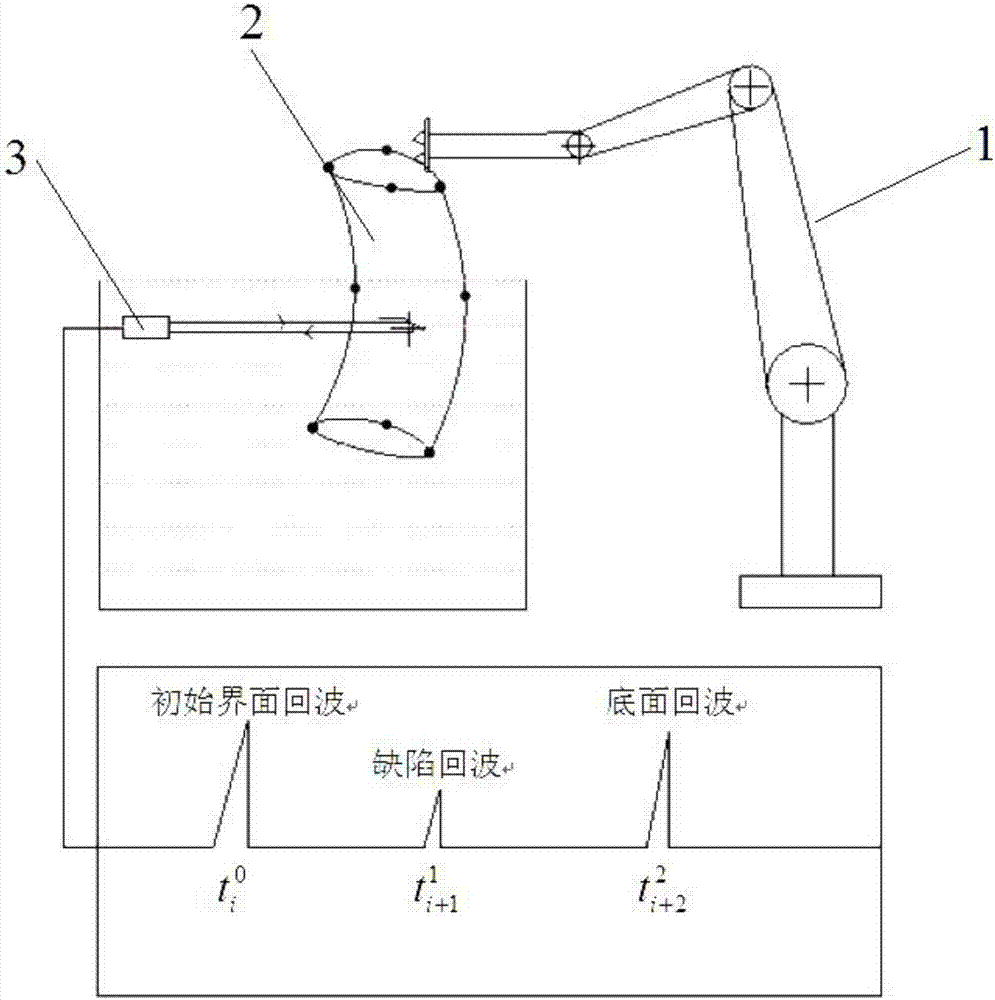

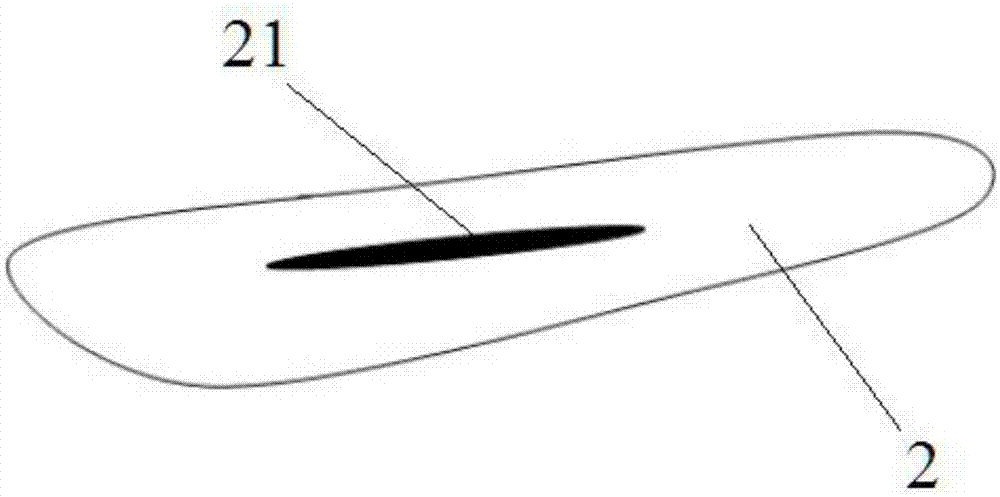

[0051] The following takes an aero-engine blade as an example of the detected workpiece, combined with the attached Figure 1-14 The three-dimensional reconstruction method of defects based on ultrasonic A-scan signals of the present invention is described in detail.

[0052] First, use ultrasonic testing to obtain defect echo information. The specific operations are as follows:

[0053] Such as figure 1 As shown in the figure, the manipulator 1 in the automated ultrasonic testing system for aero-engine blades is used to clamp the aero-engine blade 2, and the automated ultrasonic testing system is used to plan the scanning trajectory of the manipulator 1, so that the manipulator 1 drives the tested aero-engine blade 2 to complete the A-scan operation, and then obtain the A-scan echo information of the aeroengine blade 2. When the automated ultrasonic testing system plans the scanning trajectory of the manipulator 1, the surface of the aero-engine blade 2 to be detected is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com