Material performance testing device for key nuclear material under complex service environment

A service environment and material performance technology, applied to measuring devices, using stable bending force to test material strength, analyzing materials, etc., can solve the problems of in-situ testing, single applied load, etc., and achieve improvement, optimization and maintenance , Compact layout, easy to assemble and install

Pending Publication Date: 2017-12-12

JILIN UNIV

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The object of the present invention is to provide a material performance test device for key nuclear materials in complex service environments, to simulate the material performance test of the SCWR reactor environment, and to solve the problem of the single load applied by the existing related material testing machines and the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

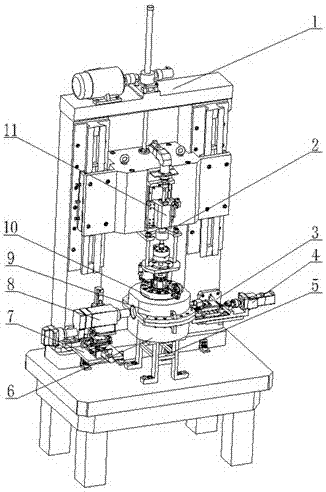

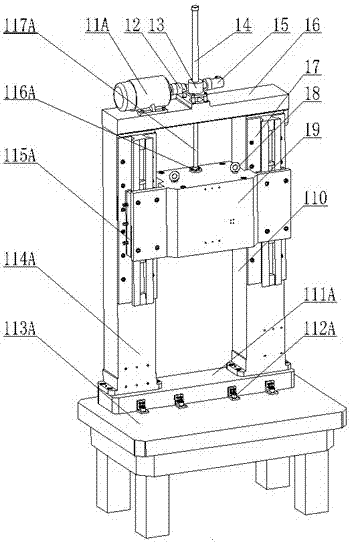

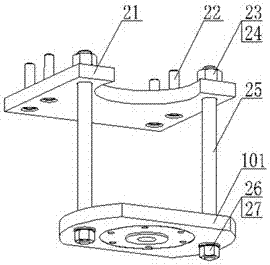

The invention relates to a material performance testing device for a key nuclear material under a complex service environment, and belongs to the technical field of material performance testing. The material performance testing device is mainly composed of a machine frame module, a lifting device, a bend loading module, an in-situ observing module, a reaction kettle module and a stretch loading module. The material performance testing device disclosed by the invention can achieve stretching-bending combined load loading and coupled loading of a supercritical water strong oxidation corrosion environment, can more really simulate a real work condition of the in-pile key nuclear material of a supercritical water reactor, and can further research micro mechanical properties of the key nuclear material. According to the material performance testing device disclosed by the invention, a modularization design is utilized, and the in-situ observing module is integrated; thus, the material performance testing device has the advantages of simple structure, compact layout and the like, microstructure of a material surface can be monitored, a material corrosion behavior can be reflected in real time, and an effective testing method for researching internal relation between microstructure morphology and macro mechanical property of the material and an initiation and propagation law of a stress corrosion crack is provided.

Description

technical field [0001] The invention relates to the technical field of material performance testing, and is used for a material performance testing device for key nuclear materials in complex service environments. Background technique [0002] As a clean energy, nuclear power has become an important part of the power industry, and nuclear power construction is being actively promoted at home and abroad. As the only nuclear reactor that uses light water as a coolant, the Supercritical Water Reactor (SCWR), it is one of the most promising fourth-generation (GEN-IV) concept reactor types that can be used to generate nuclear energy. The steam uses a direct cycle method to drive a turbo generator to generate electricity, and has the advantages of high thermal efficiency and simplified nuclear power plant construction. [0003] The coolant of SCWR is supercritical water (SCW) exceeding the critical point of water (374°C, 22.1MPa), which has extremely high requirements on the stru...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08G01N3/20G01N17/00

CPCG01N3/08G01N3/20G01N17/00Y02E30/30

Inventor 赵宏伟王赵鑫张富张世忠张建海

Owner JILIN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com