Method and device for measuring longitudinal displacement of steel rail

A longitudinal displacement, rail technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as poor vibration resistance and low data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

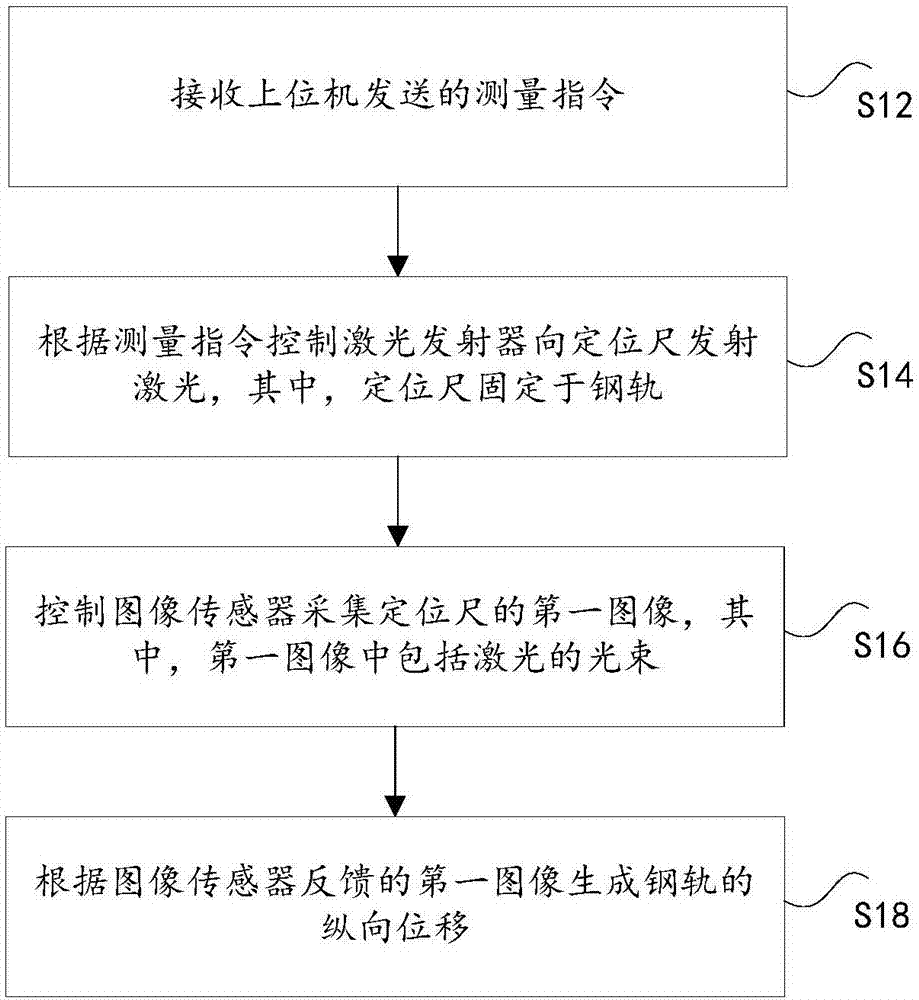

[0017] According to an embodiment of the present invention, an embodiment of a method for measuring the longitudinal displacement of a rail is provided. It should be noted that the steps shown in the flowchart of the accompanying drawings can be executed in a computer system such as a set of computer executable instructions, Also, although a logical sequence is shown in the flowchart, in some cases, the steps shown or described may be performed in a different order than here.

[0018] figure 1 It is a flowchart of a method for measuring the longitudinal displacement of a rail according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0019] Step S12, receiving the measurement instruction sent by the upper computer.

[0020] Specifically, in this solution, the measurement sensor device can be used to establish a communication relationship with the host computer, and the host computer can send a measurement instruction to ...

Embodiment 2

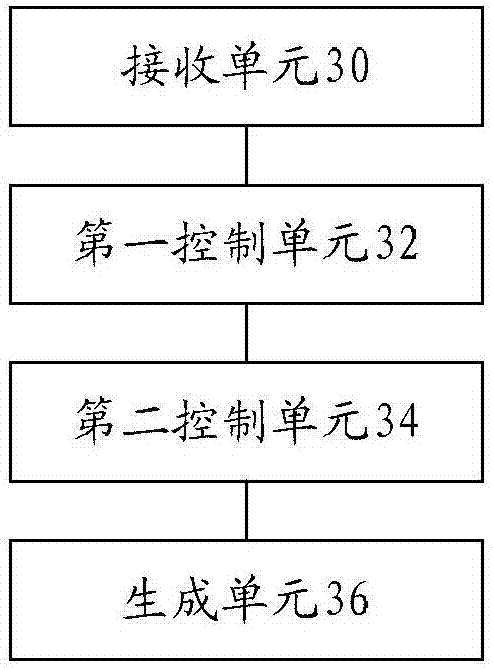

[0045] This application also provides a device for measuring the longitudinal displacement of a rail, such as image 3 As shown, the device may include: a receiving unit 30 for receiving measurement instructions sent by a host computer; a first control unit 32 for controlling the laser transmitter to emit laser light to the positioning ruler according to the measurement instruction, wherein the positioning ruler is fixed on the rail The second control unit 34 is used to control the image sensor to collect the first image of the positioning ruler, wherein the image includes the laser beam; the generation unit 36 is used to generate the longitudinal displacement of the rail according to the first image fed back by the image sensor.

[0046] In this embodiment, the measurement instruction sent by the host computer is received; the laser transmitter is controlled to emit laser light to the positioning ruler according to the measurement instruction, wherein the positioning ruler is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com