Polymer SRX asphalt road construction process

A technology of road construction and polymer, which is applied in the direction of roads, roads, climate change adaptation, etc., can solve problems such as road cracking, collapse, and failure to meet the use requirements, so as to prolong the service life, reduce the thickness of the surface layer, and improve road cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

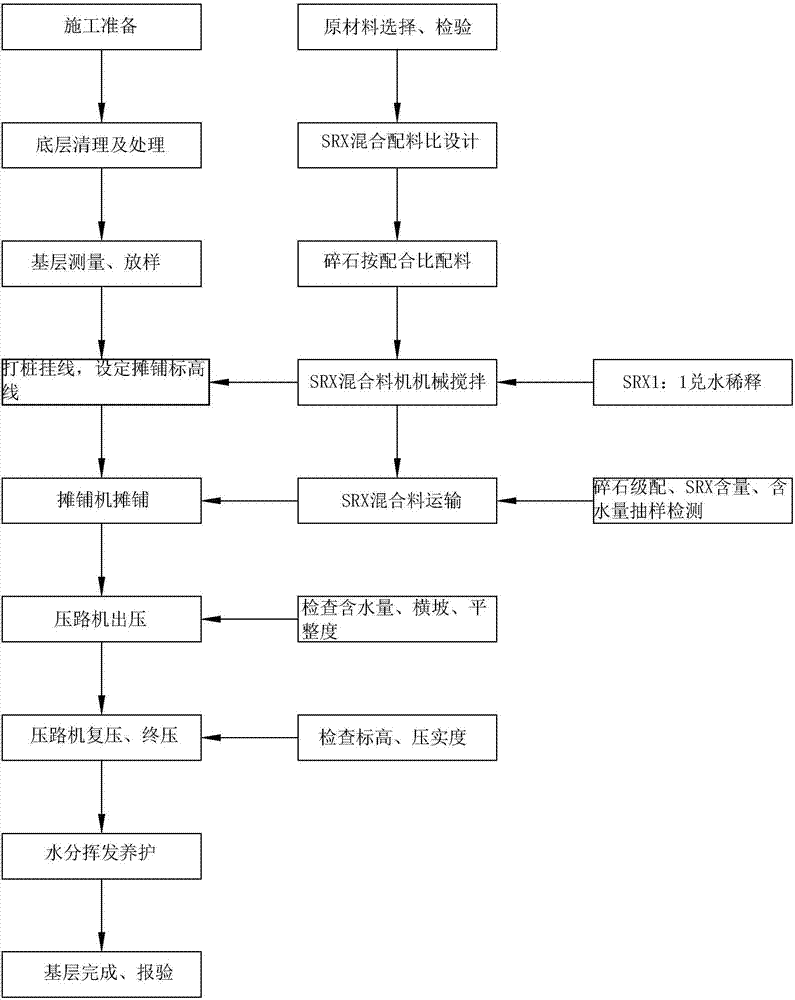

[0037] Embodiment 1: a kind of polymer SRX asphalt road construction technology, with reference to the attached figure 1 , the polymer SRX asphalt road construction process here is suitable for the construction of semi-rigid base asphalt pavement.

[0038] Step A:

[0039] Preparations required before construction.

[0040] Specifically, the underlayment of the road is made into a trough section. For the road section made of trough section, excavate drainage ditches alternately at intervals of 5-10m on the shoulders on both sides. The underlying layer meets the road arch, flatness and compaction specified in the construction. Complete the re-measurement of the guide points and benchmarking points on both sides of the road required for construction.

[0041] Step B:

[0042] Bottom cleaning and treatment.

[0043] Specifically, before filling the foundation of the foundation filling section, the earth shall be bulldozed first, and then the earthwork excavated at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com