Sludge drying and reducing device and method

A sludge drying and reduction technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. Scraping and other problems, to achieve the effect of good sealing, low thermal energy consumption, and preventing air from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

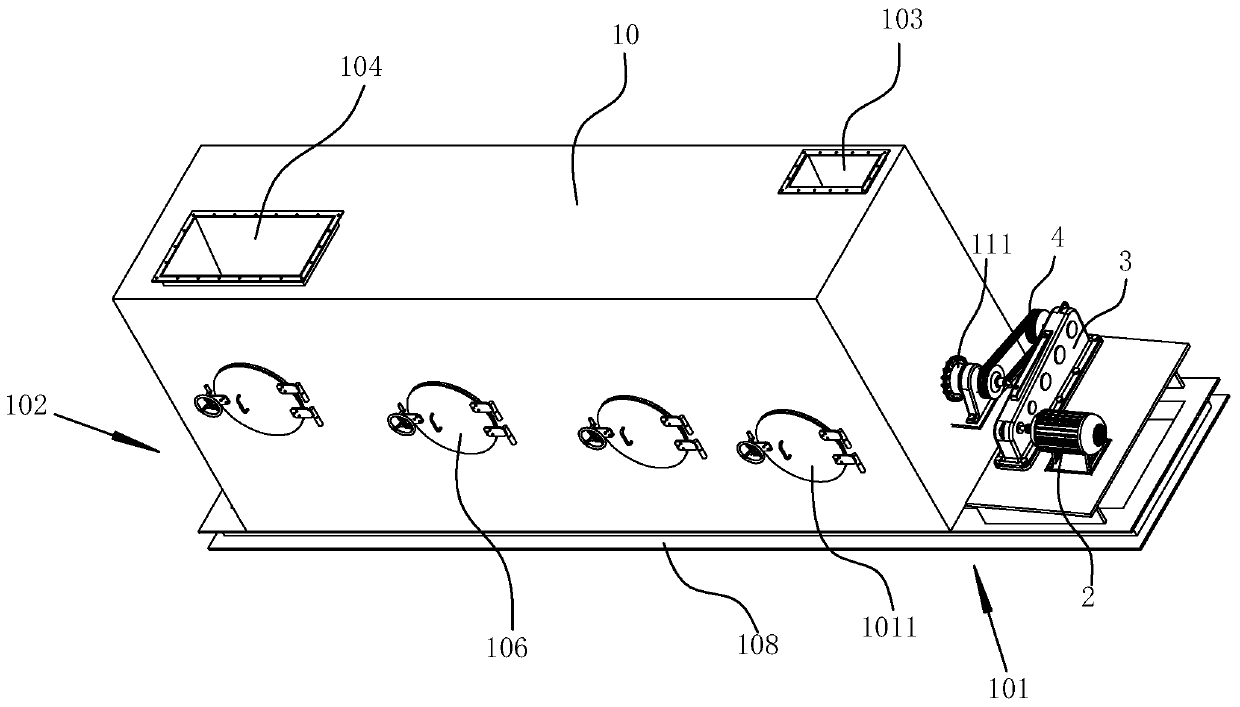

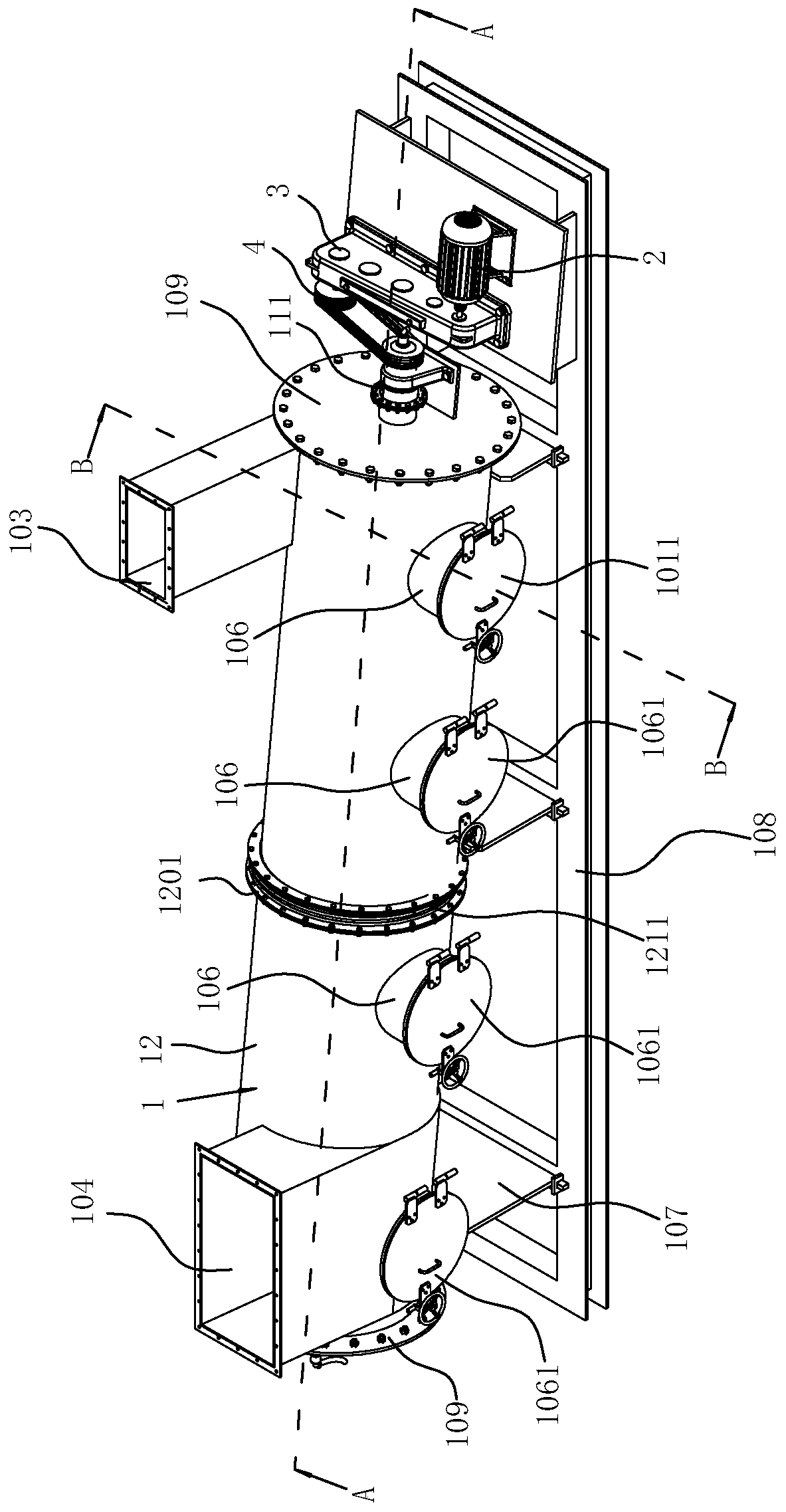

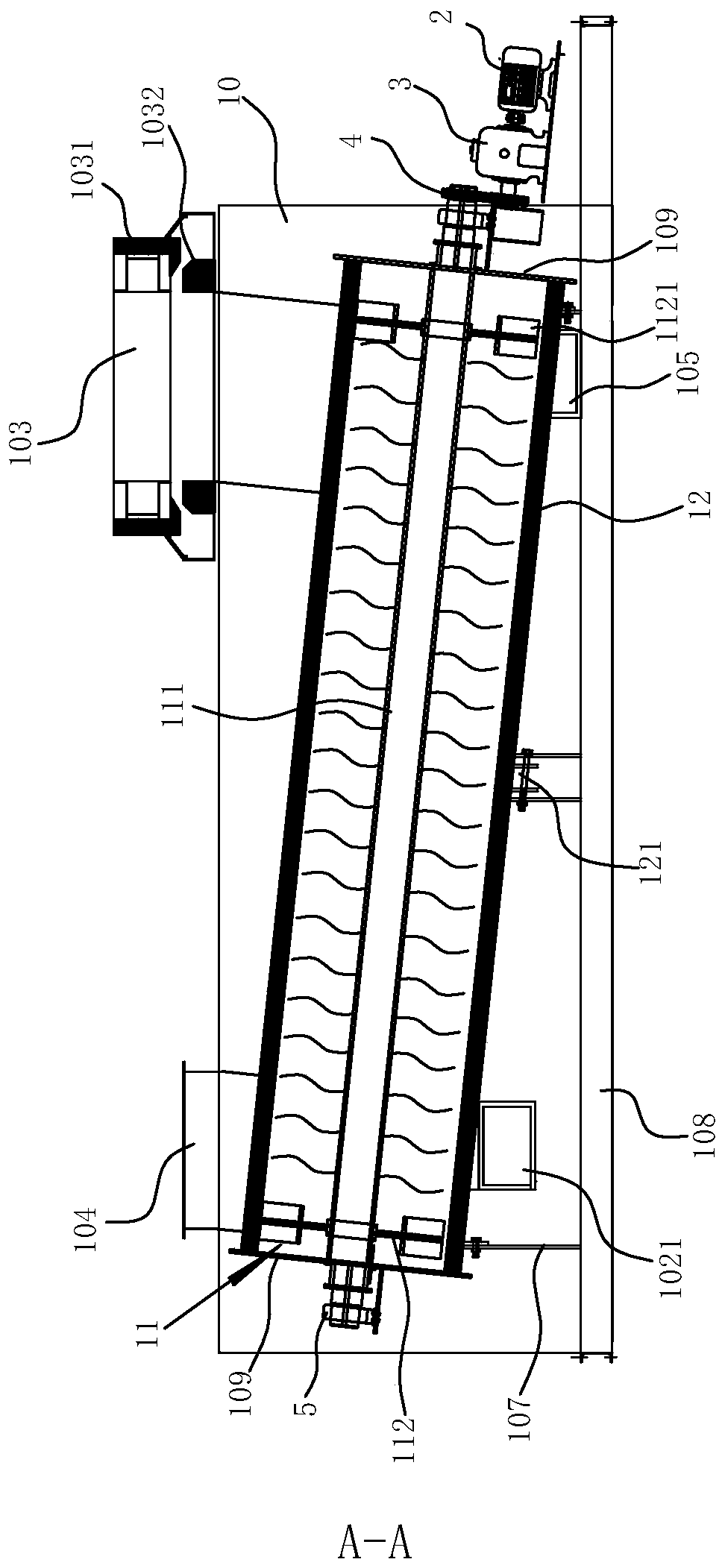

[0040] Figure 1 to Figure 4 It schematically shows a sludge drying and reducing device provided according to the first embodiment of the present invention.

[0041] Such as Figure 1 to Figure 3 As shown, the sludge drying and reducing device disclosed in the present invention includes a horizontally arranged hollow cylindrical drying cylinder 1, and the two ends of the drying cylinder 1 are sealed by the second flange 109, in order to improve the connection between the second flange 109 and the drying cylinder 1. To ensure the tightness between them, a sealing strip structure (not shown in the figure) is provided at the joint of the second flange 109 . The drying cylinder 1 comprises a feed end 101 and a discharge end 102 positioned at two ends of the drying cylinder 1, such as figure 1 As shown, its feed port 101 is provided with a feed port 1011, and the feed port 1011 is located on the side of the drying cylinder 1 cylinder body, and its position takes into account the co...

Embodiment 2

[0053] A sludge drying and reducing device disclosed in Example 2 of the present invention is basically the same as in Example 1, the difference is that:

[0054] In this embodiment of the present invention, the blades 1122 of the material propulsion unit 11 form an included angle of 30° with the radial plane of the rotating shaft 111, and all the blades 1122 are in the same direction; the total length of the drying cylinder 1 is 5 m.

[0055] A kind of sludge drying reduction method disclosed in Example 2 of the present invention is also basically the same as in Example 1, the difference is:

[0056] Step S2: Pass the flue gas at 850°C generated by the sludge incinerator through the air inlet 103 of the drying cylinder 1, while controlling the flue gas feeding speed at 3m / s.

[0057] In the sludge drying and reducing device and method disclosed in this embodiment of the present invention, the 850°C high-temperature flue gas generated by the sludge incinerator passes through t...

Embodiment 3

[0059] A kind of sludge drying and reducing device disclosed in embodiment 3 of the present invention is basically the same as in embodiment 1, the difference is:

[0060] In this embodiment of the present invention, the blades 1122 of the material propulsion unit 11 form an included angle of 60° with the radial plane of the rotating shaft 111, and all the blades 1122 are in the same direction; the total length of the drying cylinder 1 is 4m.

[0061]A kind of sludge drying reduction method disclosed in Example 2 of the present invention is also basically the same as in Example 1, the difference is:

[0062] Step S2: Pass the flue gas at 950°C generated by the sludge incinerator through the air inlet 103 of the drying cylinder 1, while controlling the flue gas feeding speed at 12m / s.

[0063] In the sludge drying and reducing device and method disclosed in this embodiment of the present invention, the 950°C high-temperature flue gas generated by the sludge incinerator passes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com