Liquid crystal panel lifting transfer device

A liquid crystal panel and transfer device technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of increased equipment manufacturing costs, high space size requirements, large space, etc., and achieve reasonable structural design, high stability, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

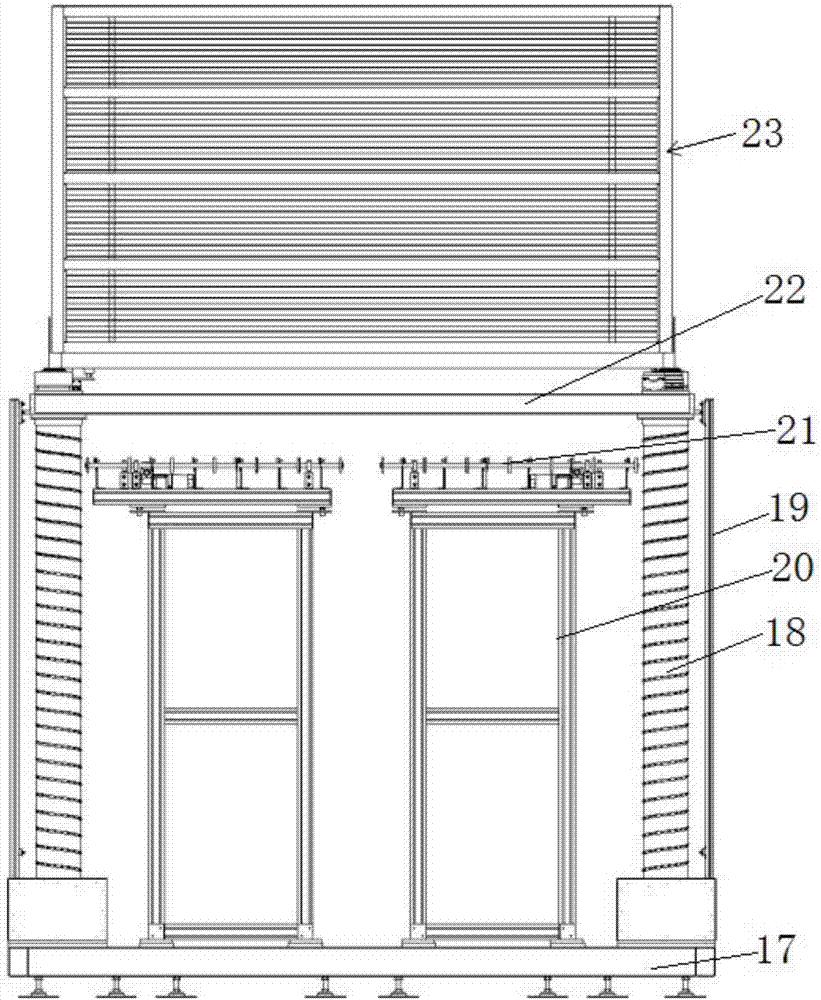

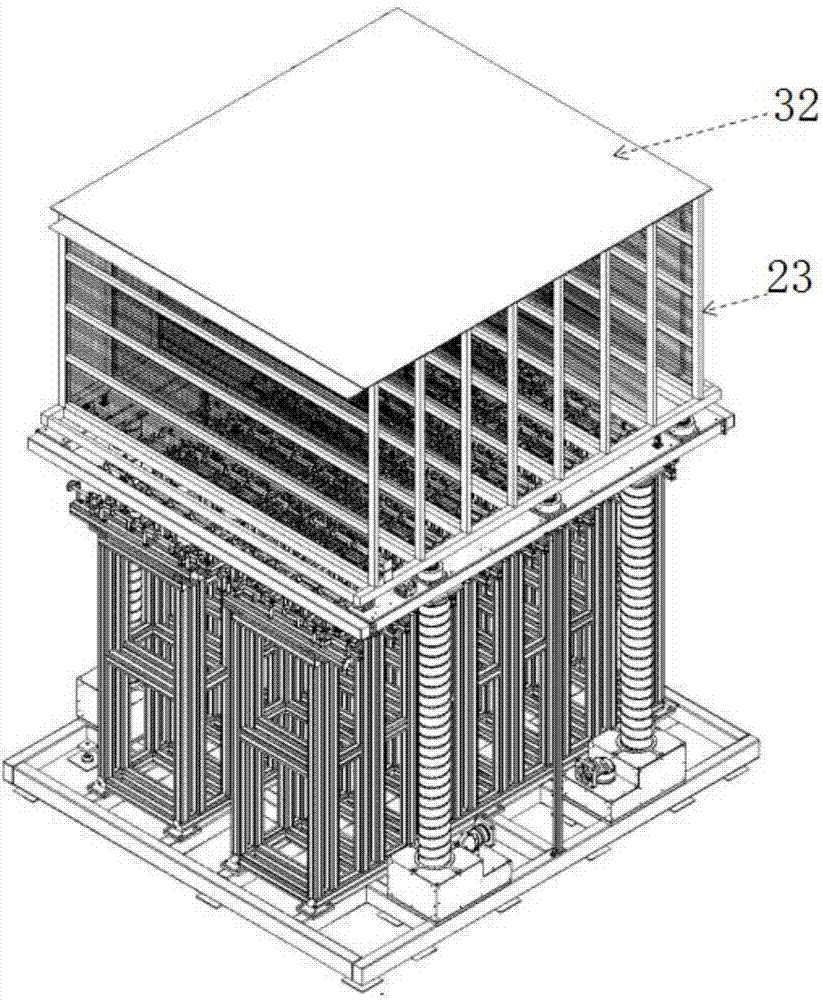

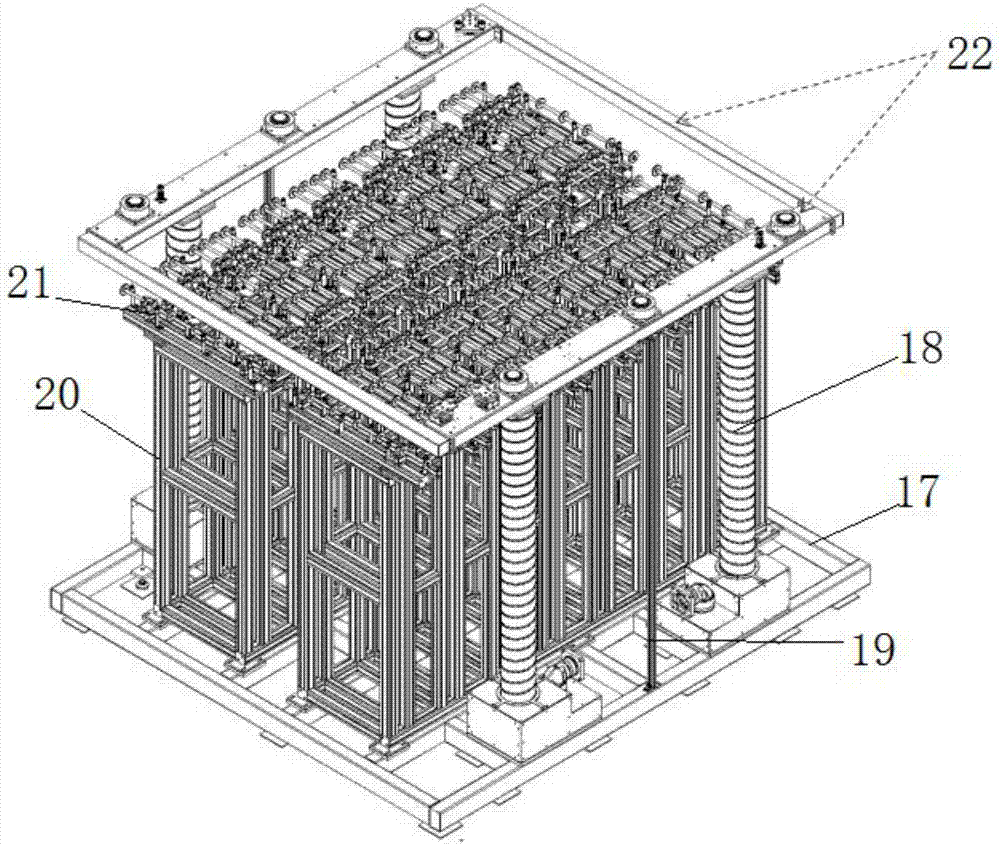

[0042] Such as Figure 5 to Figure 10 As shown, the screw jack 18 includes a fixed base, a platform that rotates around the fixed base, a storage box 6 installed on the platform, a spring flat belt 1 stored in the storage box 6, installed in the fixed base and Cooperate with the spring flat belt 1 to form the toothed spring bar 2 of the spiral cylinder, the belt track lifting mechanism installed on the platform for binding the toothed spring bar 2 to lift or shrink the movement 3, used to make the spring flat belt 1 and the tooth The track guide frame 4 that type spring bar 2 interlocks. The lifting motor 24 drives the platform to rotate, and then drives the belt track lifting mechanism 3 to rotate, and the belt track lifting mechanism 3 makes the toothed spring bar 2 rise and fall under the guidance of the belt track lifting mechanism 3, and synchronously pulls the spring flat belt 1 spiral Climbing, under the pushing effect of the rail guide frame 4, the spring flat belt 1 ...

Embodiment 2

[0057] Such as Figure 13 to Figure 16 As shown, the screw jack 18 includes a fixed base, a platform that rotates around the fixed base, a storage box 6 installed on the platform, a spring flat belt 1 stored in the storage box 6, installed in the fixed base and Cooperate with the spring flat belt 1 to form the toothed spring bar 2 of the spiral cylinder, the belt track lifting mechanism installed on the platform for binding the toothed spring bar 2 to lift or shrink the movement 3, used to make the spring flat belt 1 and the tooth The track guide frame 4 that type spring bar 2 interlocks. The lifting motor 24 drives the platform to rotate, and then drives the belt track lifting mechanism 3 to rotate, and the belt track lifting mechanism 3 makes the toothed spring bar 2 rise and fall under the guidance of the belt track lifting mechanism 3, and synchronously pulls the spring flat belt 1 spiral Climbing, under the pushing effect of the rail guide frame 4, the spring flat belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com