An Air Suspension System for the Follow-up Rear Axle of a Light Truck

A technology of air suspension and truck, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of poor lateral stability, large vertical layout space, complex structure, etc., to meet the requirements of safety and smoothness performance, reduce fuel consumption and improve economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

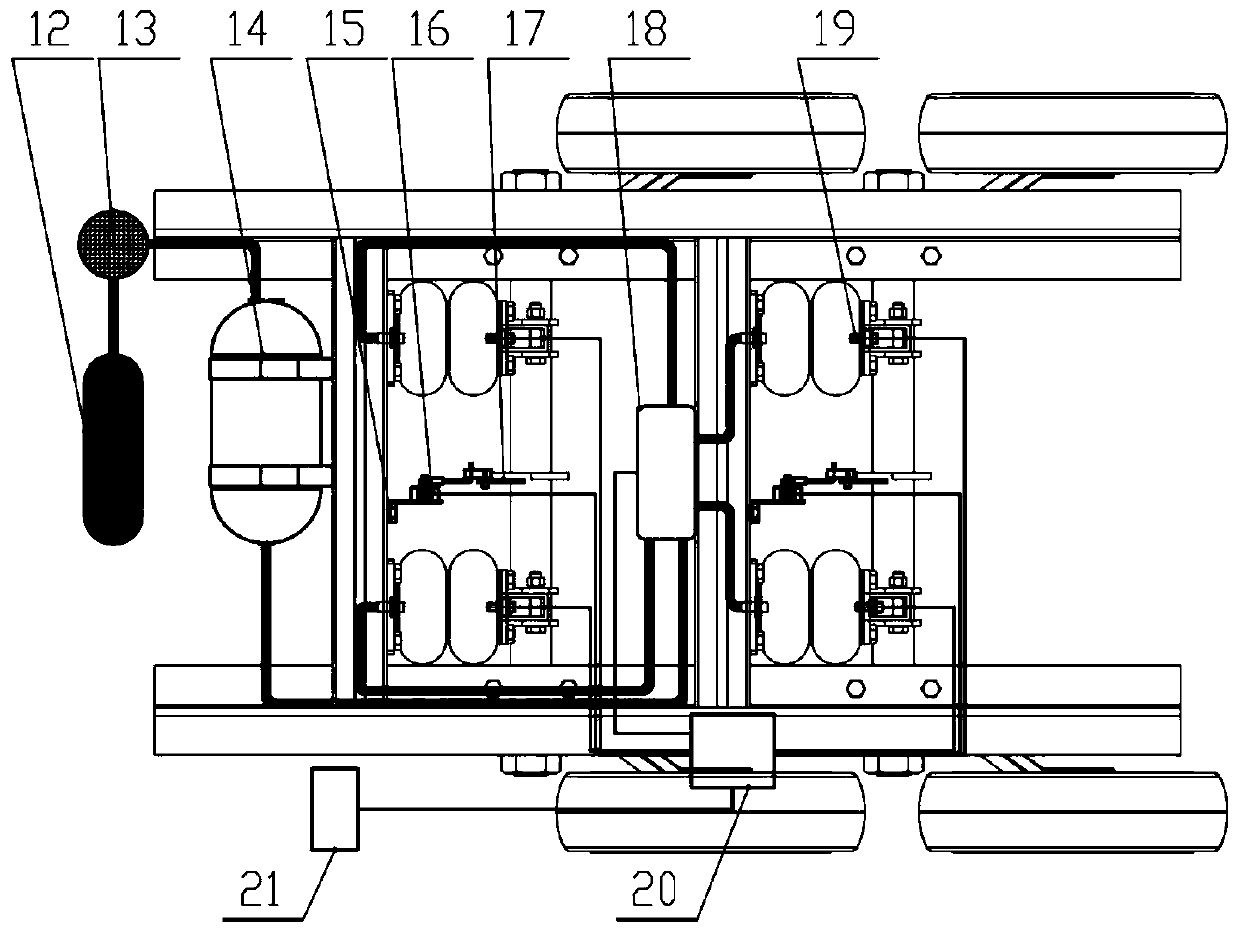

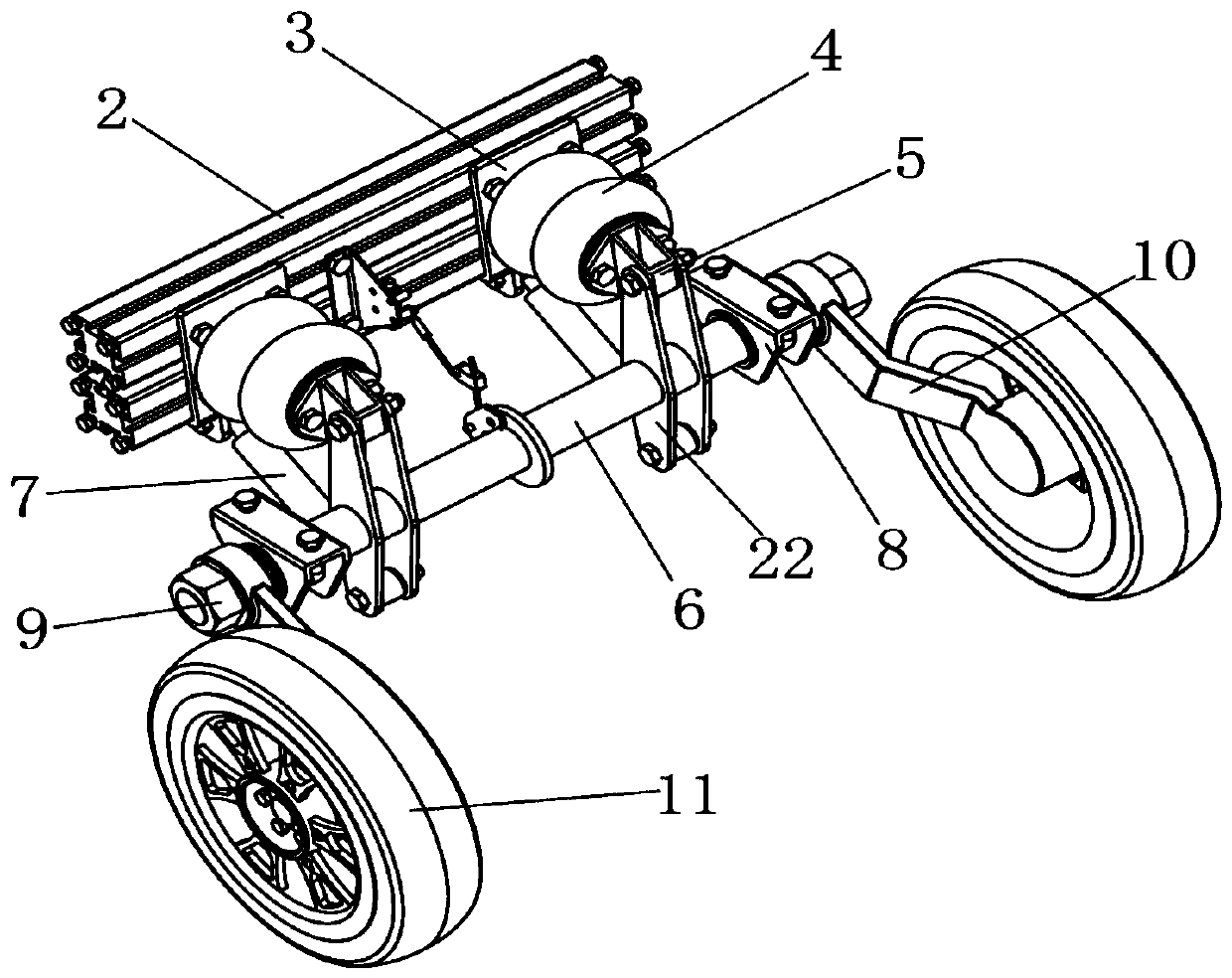

[0029] The invention provides an air suspension system of a follower rear axle of a light truck, which comprises an air suspension device and an air pressure control assembly. Such as figure 1 , 3 As shown in and 4, the air suspension device includes two longitudinal beams 1 arranged in parallel, at least one set of single rear axle assembly is arranged between the two longitudinal beams 1, preferably two groups; the single rear axle assembly includes two The crossbeam 2 between the longitudinal beams 1 is provided with two airbags 4 and fixed brackets 3 arranged in parallel along the direction of the longitudinal beams. An axle 6 corresponding to the crossbeam 2 is also arranged between the two longitudinal beams 1, and the axle 6 Installed in the axle fixed seat 8 on the longitudinal beam 1 through a cylindrical roller bearing, and the axle 6 can rotate in the axle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com