Goose feather tube writing brush and manufacturing method thereof

A production method and goose feather tube technology, which can be applied to other ink pens, printing, writing utensils, etc., can solve problems such as cost reduction, and achieve the effect of long storage time and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

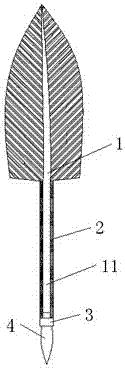

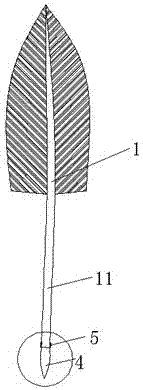

[0030] Such as Figure 1-3 As shown, a quill writing brush includes a quill shaft 1, the lower part of the quill shaft 1 is a quill 11, the quill 11 is covered with a decorative layer 2, and the lower end of the quill 11 is connected with a fixed head 3 , one end of the fixed head 3 is plugged and connected with the nozzle of the quill 11 , and the other end is plugged with the nib 4 .

[0031] Specifically, one end of the fixed head 3 is cylindrical and inserted into the mouth of the quill 11 to interfere with the quill 11, the outer surface of the fixed head 3 outside the mouth is flush with the decorative layer 2, and the outer surface of the fixed head 3 The shape can be cylindrical or trumpet-shaped.

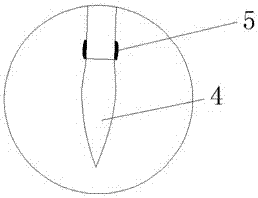

[0032] A quill writing brush, comprising a quill holder 1, the lower part of the quill holder 1 is a quill 11, the end of the quill 11 is a nozzle of the quill 11, and a nib 4 is inserted in the nozzle, so The position where the nib 4 is plugged into the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com