Cam-controlled follow-up pressure roller mechanism

A pressure roller mechanism and cam control technology, applied in printing machines, general parts of printing machinery, printing, etc., can solve the problems of not being able to meet the requirements of high-precision printing product inspection, difficult to control friction, and out-of-control paper movement, etc., to achieve Ensure the effect of stability, convenient operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

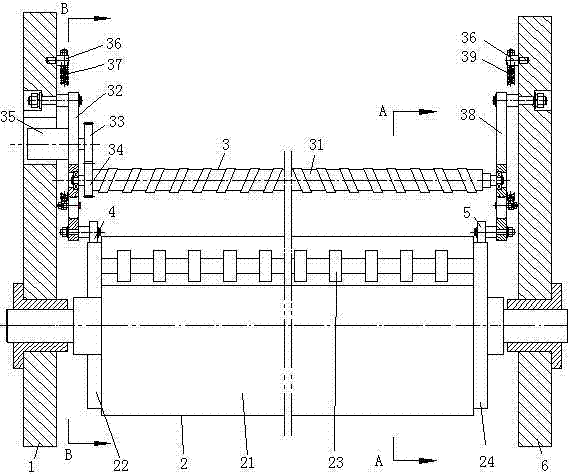

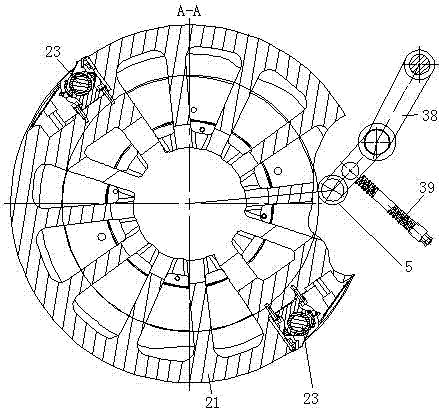

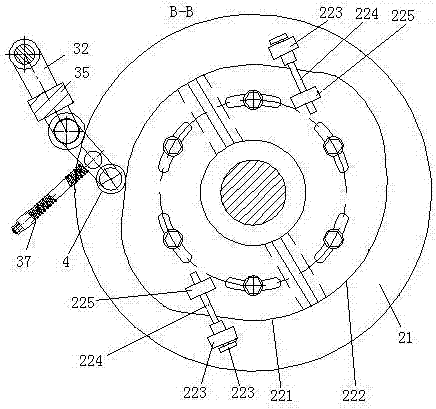

[0013] Refer to attached figure 1 , attached figure 2 , attached image 3 , a cam-controlled follower pressure roller of the present invention

[0014] Mechanism, which is composed of wallboard Ⅰ1, roller mechanism 2, pressure roller mechanism 3, rolling part Ⅰ4, rolling part Ⅱ5, wallboard Ⅱ6, the roller mechanism 2 is supported on the wallboard Ⅰ1 and wallboard Ⅱ6 through the supporting parts; the pressure roller mechanism 3 is set on the wallboard I1 and wallboard II6; the rolling element I4 and the rolling element II5 are arranged on the roller mechanism 3 through the shaft; the roller mechanism 3 is composed of the roller 31, the connecting plate I32, the gear I33, and the gear II34 , a motor 35, a connecting shaft 36, a compression spring assembly I37, a connecting plate II38, and a compression spring assembly II39. The pressure roller 31 is a rubber roller body with opposite helical directions in the left and right parts; the connecting plate I32, The connecting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com