Intermittent rotating mechanical processing workbench and preparation method thereof

A machining and workbench technology, applied in workbenches, metal processing equipment, metal processing machinery parts, etc., can solve problems such as limiting the automation level of equipment, and achieve the effect of ensuring certainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

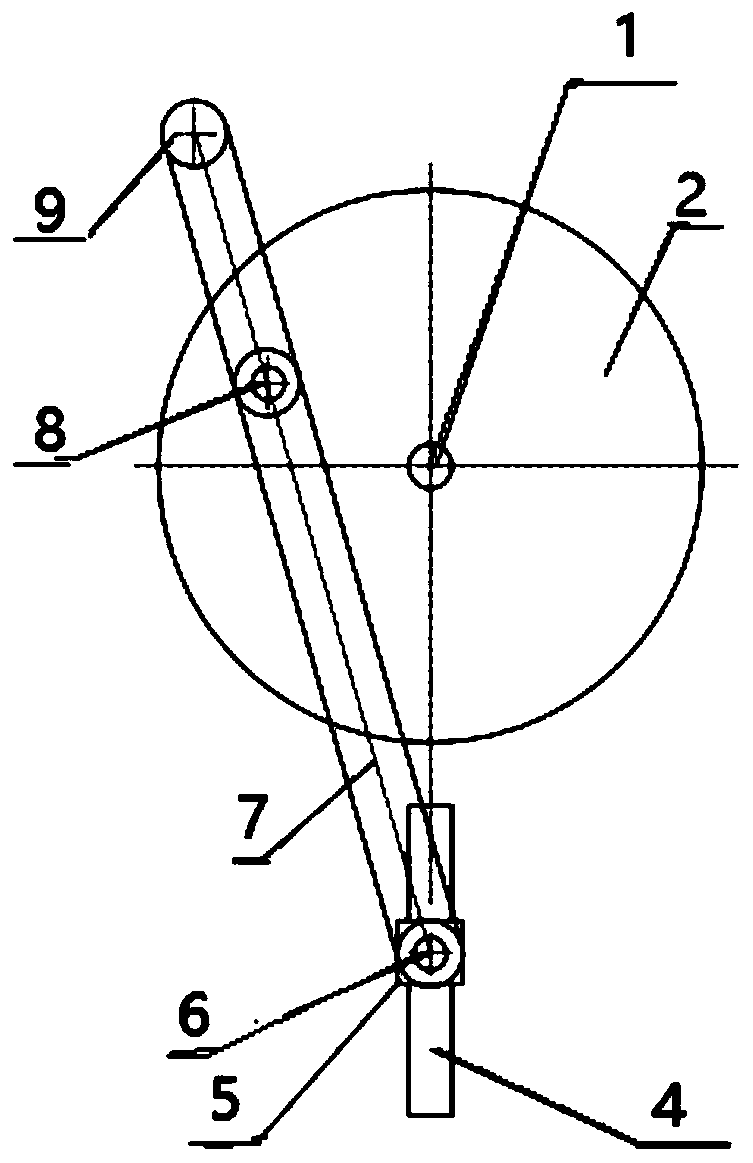

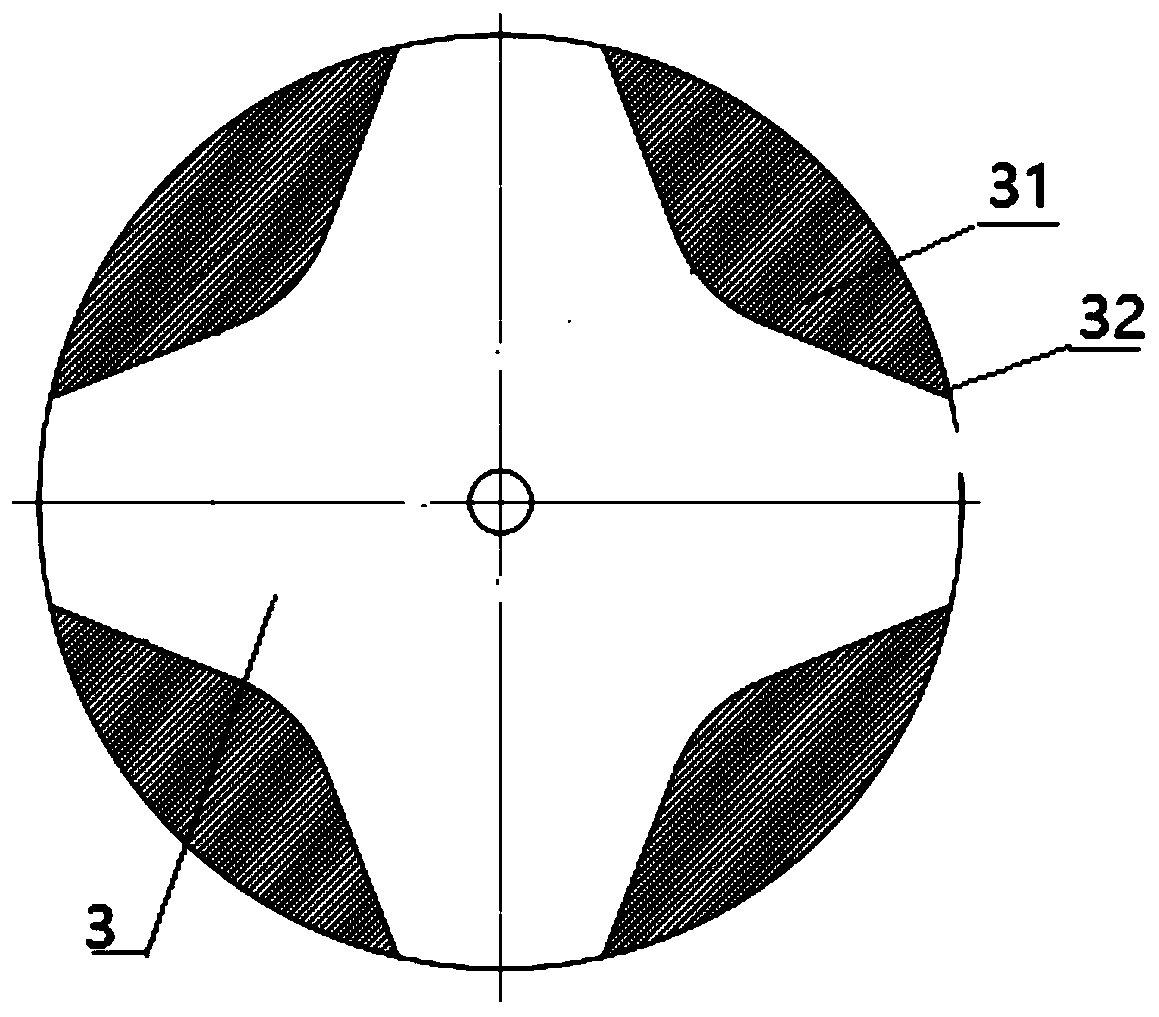

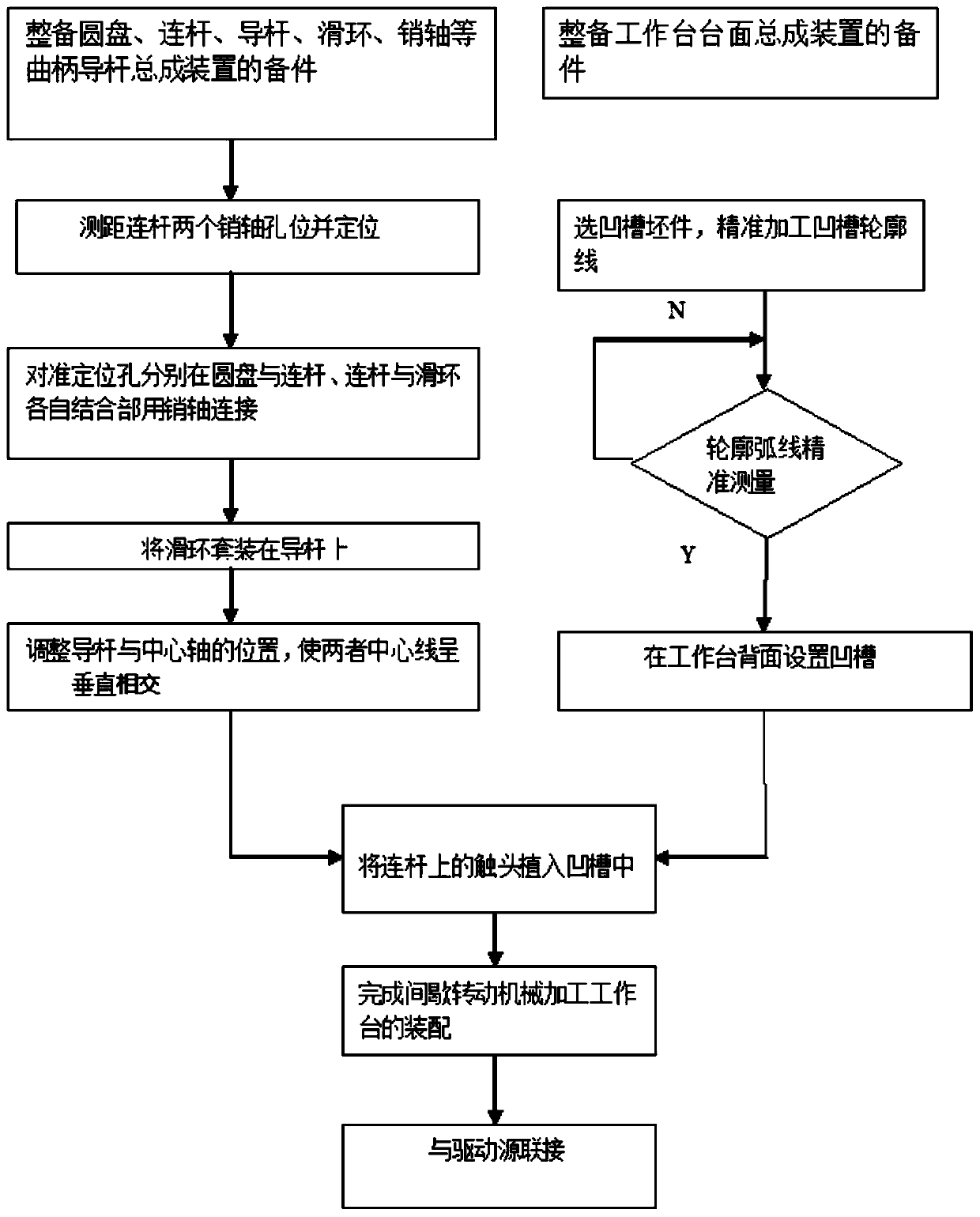

[0022] The present invention is described in detail in conjunction with the accompanying drawings and with the following embodiments: see attached figure 1 , attached figure 2 , attached image 3 , the present invention relates to an intermittent rotary machining workbench, similarly, the present invention can also be used for the assembly line rotary platform required for intermittent production. It includes a central shaft 1 and a disc 2 fixed on the central shaft 1 and rotating together with the central shaft. The disc is connected with the connecting rod 7 through the pin shaft 8, and the other end of the connecting rod is connected with the slip ring 5 through the pin shaft 6. The ring 5 slides freely on the guide rod 4; the extension end of the connecting rod 7 moves along the outline 32 of the groove in the special structure groove 31 on the back of the workbench 3 through the contact 9, so that the workbench can be pushed to realize intermittent movement. Especially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com