A preheating and surfacing device for wear-resistant layer of limestone crushing roller

A technology for crushing rollers and wear-resistant layers, which is applied in the field of preheating and surfacing devices for wear-resistant layers of limestone crushing rollers, and can solve problems such as potential safety hazards, reduction of labor intensity of operators, production safety, large volume and weight of limestone crushing rollers, etc. , to achieve the effects of low energy consumption, reduced labor intensity, production safety, and high heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

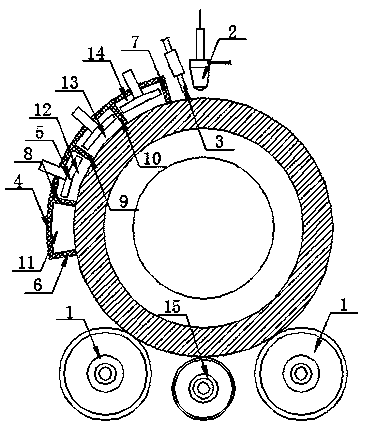

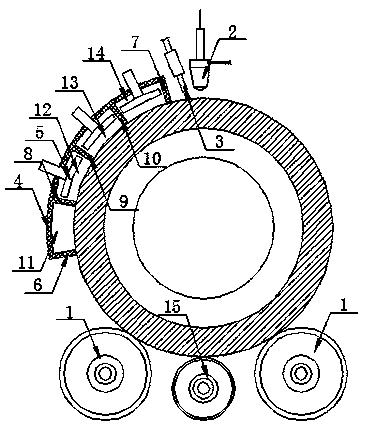

[0013] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0014] Such as figure 1 As shown, a limestone crushing roller wear-resistant layer preheating surfacing device includes two surfacing rotating support rollers 1 arranged at the bottom of the crushing roller placed horizontally on the axis, and a wear-resistant layer surfacing roller 1 arranged above the top surface of the crushing roller. Welding gun 2 and surfacing welding powder nozzle 3, the surfacing welding preheating arc-shaped cover plate 4 which is arranged on the roller surface of the crushing roller and is located on the side of the wear-resistant layer surfacing welding torch 2; the two surfacing welding rotary supports The axes of the rollers 1 are all horizontal and parallel to the crushing rollers, and the two surfacing rotating support rollers 1 are arranged symmetrically with respect to the vertical plane passing the axis of the crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com