Modularized thermal insulation device

A heat preservation device and heat preservation module technology, applied in heat preservation, pipeline protection, pipeline protection through heat insulation, etc., can solve the problems of heating wire burning, low work efficiency, waves, etc., to facilitate installation and disassembly, improve heat preservation effect, The effect of improving the degree of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

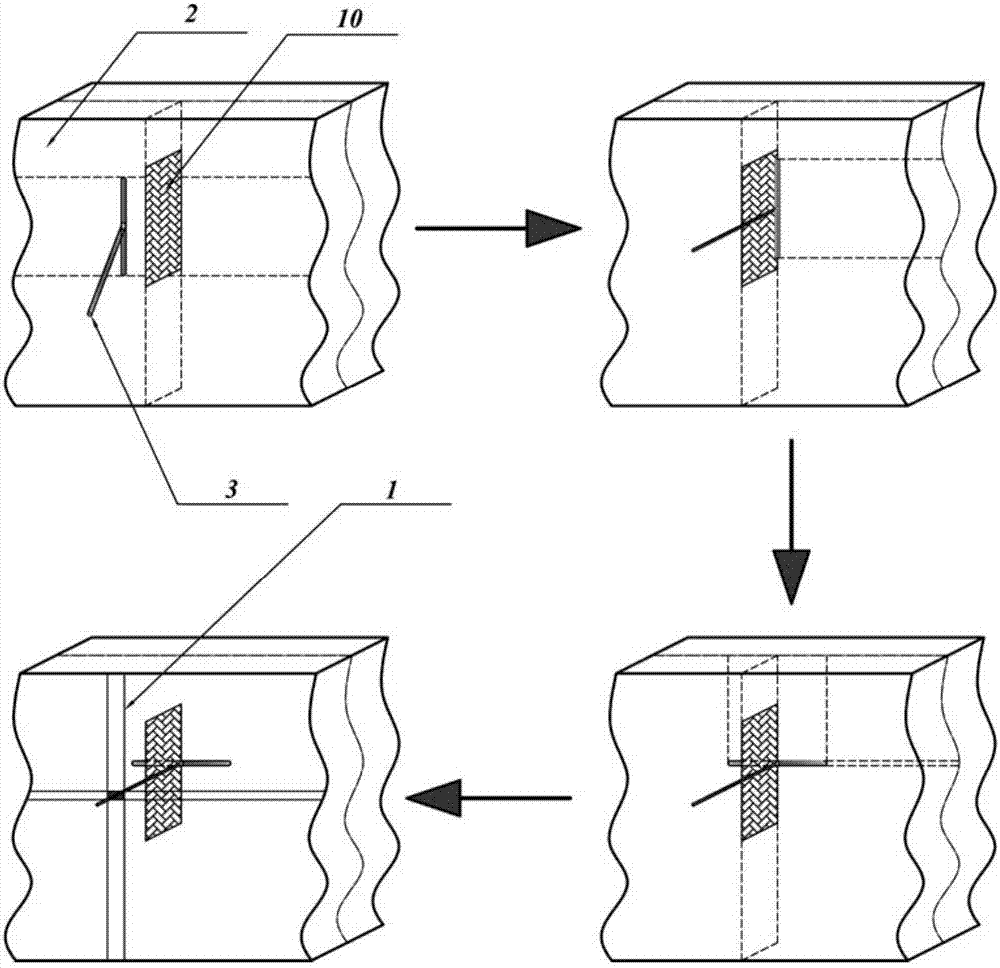

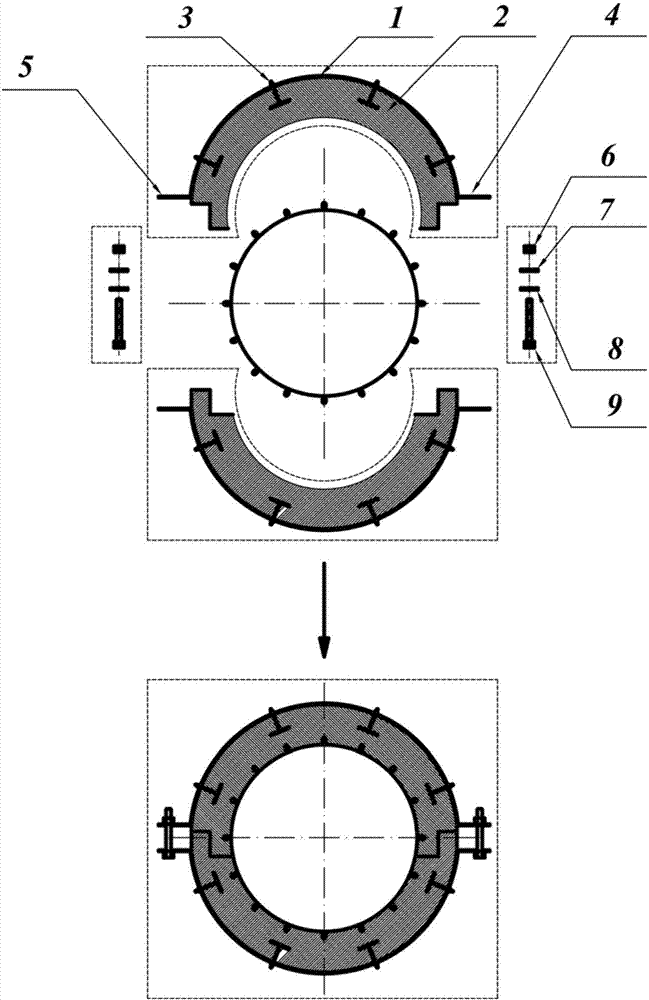

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

[0022] The present invention is a modular heat preservation device, which includes multiple groups of heat preservation modules and connecting structures; each heat preservation module is composed of four parts: metal shell 1, heat preservation material 2, cross structure 3 and multiple groups of bolt connection through holes; each group The connection structure is composed of nuts 6, No. 1 washer 7, No. 2 washer 8 and bolts 9; the adjacent insulation modules are matched by misalignment, and bolts are used to compress the insulation modules with the outer walls of equipment and pipes; and The heat preservation device and the outer wall of the equipment and pipes are compacted through the connecting bolts on the left and right, so as to meet the heat preservation requirements; for some equipment and pipes that require heating and heat preservation, they a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com