Pulling-pressing shaft type monorail beam supporting seat

A finale, single-track technology, applied in the field of rail transit, can solve problems such as unfavorable anchor bolt fatigue life, contact stress fatigue pitting, anchor bolt fatigue damage, etc., to improve fatigue resistance safety, reduce friction, and reduce construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

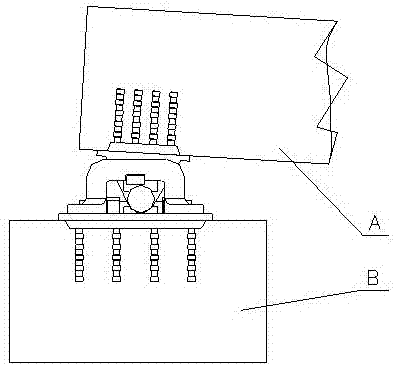

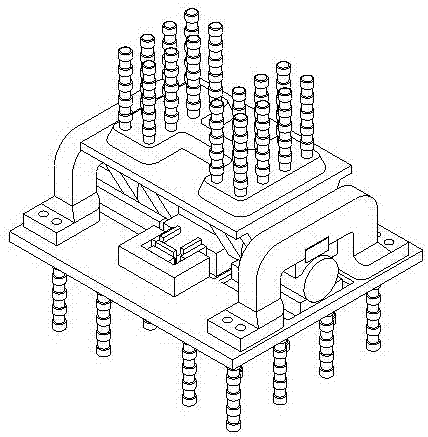

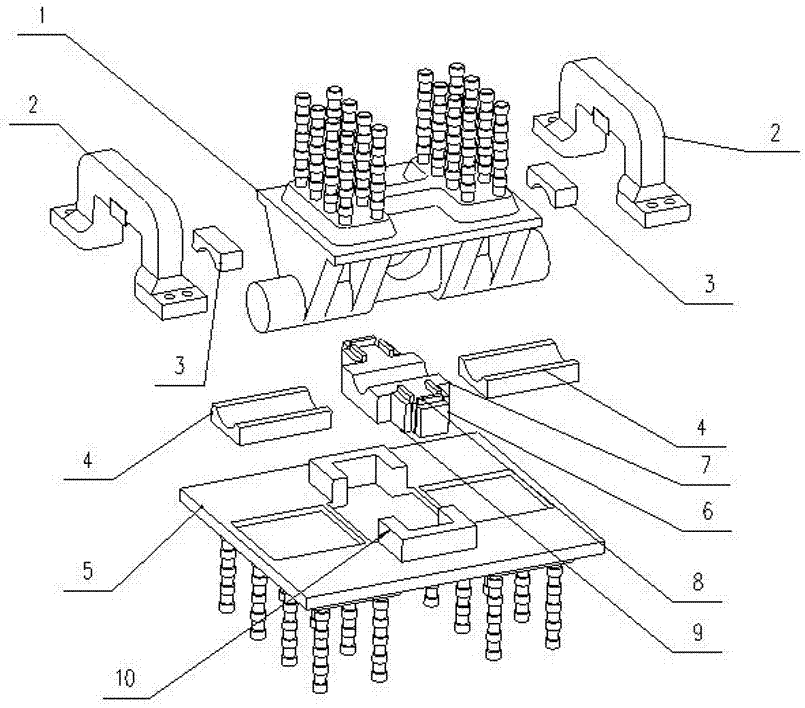

[0031] Such as figure 2 , 3 As shown, a tension and compression axis type monorail beam bearing includes an upper pendulum 1 and a lower bearing plate 4 .

[0032] On the support, a pendulum 1 such as Figure 4 , 5 As shown, it includes an upper top plate 1-1 and a horizontal cylinder fixedly arranged below it. The cylinder is divided into a positioning cylinder 1-6 in the middle and a rotating cylinder 1-7 coaxial with it at both ends. , the diameter of the positioning cylinder 1-6 is smaller than the diameter of the rotating cylinder 1-7 so as to form a stepped surface. The fixed connection between the cylindrical surface and the upper top plate 1-1 is realized through axial ribs 1-2 and radial ribs 1-3. A shear boss 1-8 is arranged on the top of the upper top plate 1-1. A reserved anchor hole 1-5 is opened in the middle of the axial rib 1-2 between the cylinder surface and the upper top plate 1-1. The rotating cylinder 1-7 protrudes from the upper top plate 1-1 cross...

Embodiment 2

[0038] A tension and compression axis type monorail beam support, comprising a support upper pendulum 1 and a lower support plate 4.

[0039] On the support, a pendulum 1 such as Figure 4 , 5 As shown, it includes an upper top plate 1-1 and a horizontal cylinder fixedly arranged below it. The cylinder is divided into a positioning cylinder 1-6 in the middle and a rotating cylinder 1-7 coaxial with it at both ends. , the diameter of the positioning cylinder 1-6 is smaller than the diameter of the rotating cylinder 1-7 so as to form a stepped surface. The fixed connection between the cylindrical surface and the upper top plate 1-1 is realized through axial ribs 1-2 and radial ribs 1-3. A shear boss 1-8 is arranged on the top of the upper top plate 1-1. A reserved anchor hole 1-5 is opened in the middle of the axial rib 1-2 between the cylinder surface and the upper top plate 1-1. The rotating cylinder 1-7 protrudes from the upper top plate 1-1 cross bridge to form a cantile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com