Ballastless track railway expansive soil cutting structure and construction method

A ballastless track and railway technology, applied in the field of geotechnical engineering, can solve problems such as arching deformation, achieve simple construction, low engineering investment, and meet the requirements of track smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

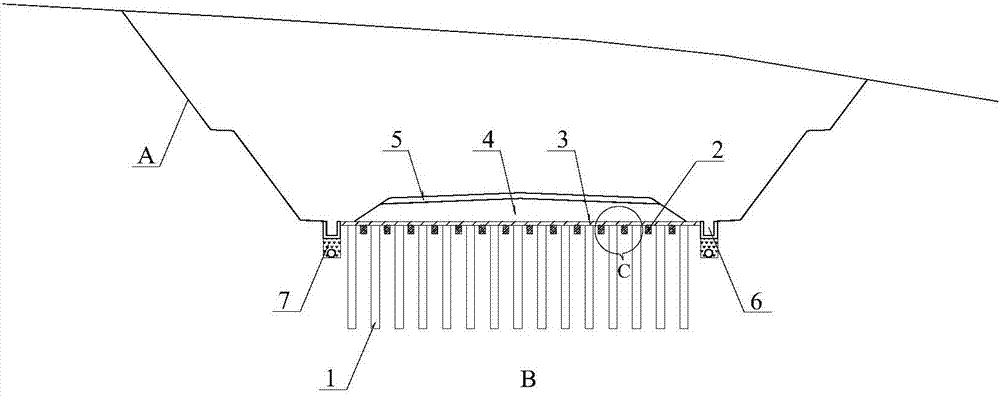

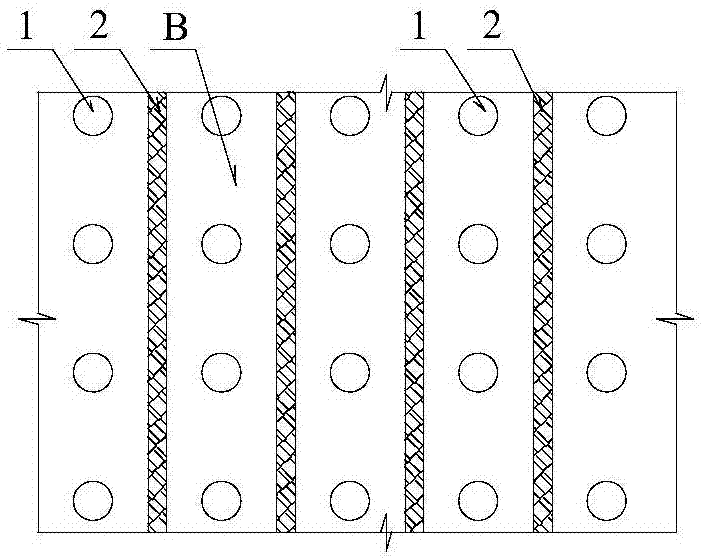

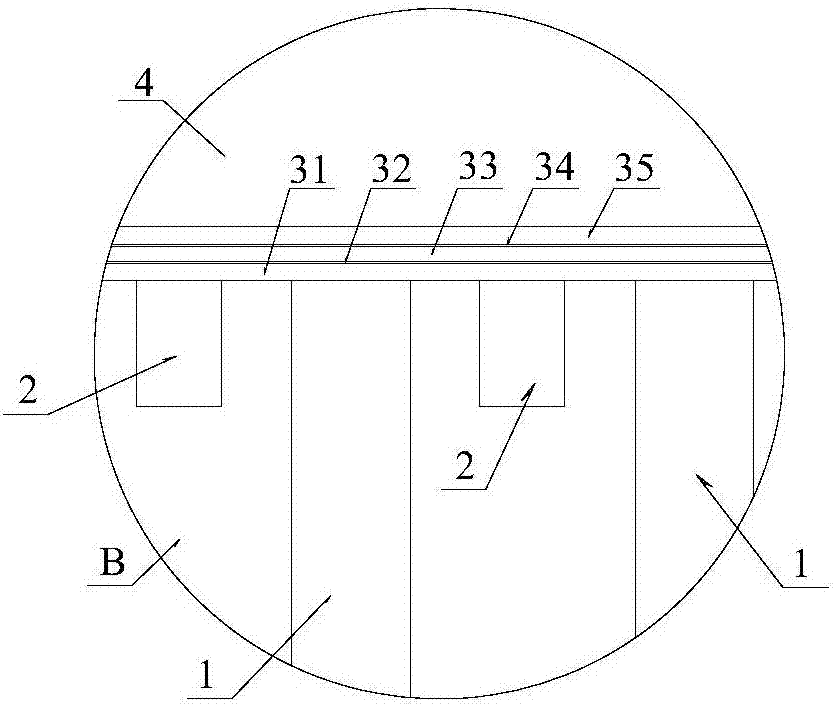

[0014] refer to figure 1 , a ballastless track railway expansive soil cutting structure of the present invention comprises: cement fly ash gravel piles 1, horizontally and vertically spaced in rows and arranged in expansive soil foundation A to form a composite foundation, the depth of which is set beyond the influence of expansive soil atmosphere Thickness; elastic geotechnical profile 2, arranged in the surface layer of expansive soil foundation A between two rows of cement fly ash gravel piles 1 in the transverse direction, extending longitudinally along the expansive soil foundation A; cushion structure 3, layered and filled in The top of the composite foundation; the bottom layer of the subgrade bed 4 and the surface layer of the subgrade bed 5, the bottom layer of the subgrade bed 4 is filled in layers on the top of the cushion structure 3, the surface layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com