Overturn preventing device of reach stacker

An anti-overturning and hoisting machine technology, which is applied to cranes and other directions, can solve the problems of complex structure design of anti-overturning mechanism, low reliability of anti-overturning, and wearing parts, so as to meet the requirements of ride comfort, low cost and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

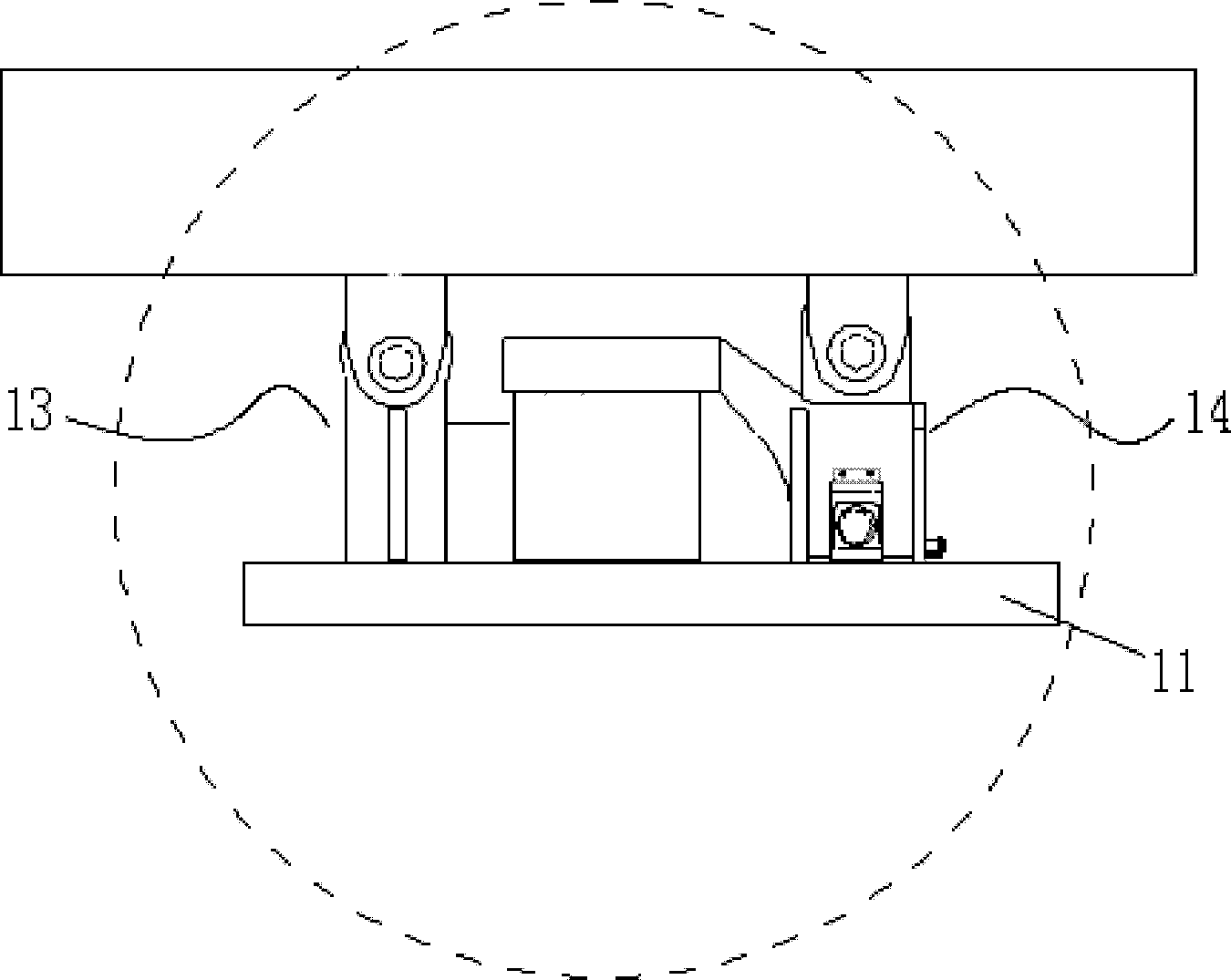

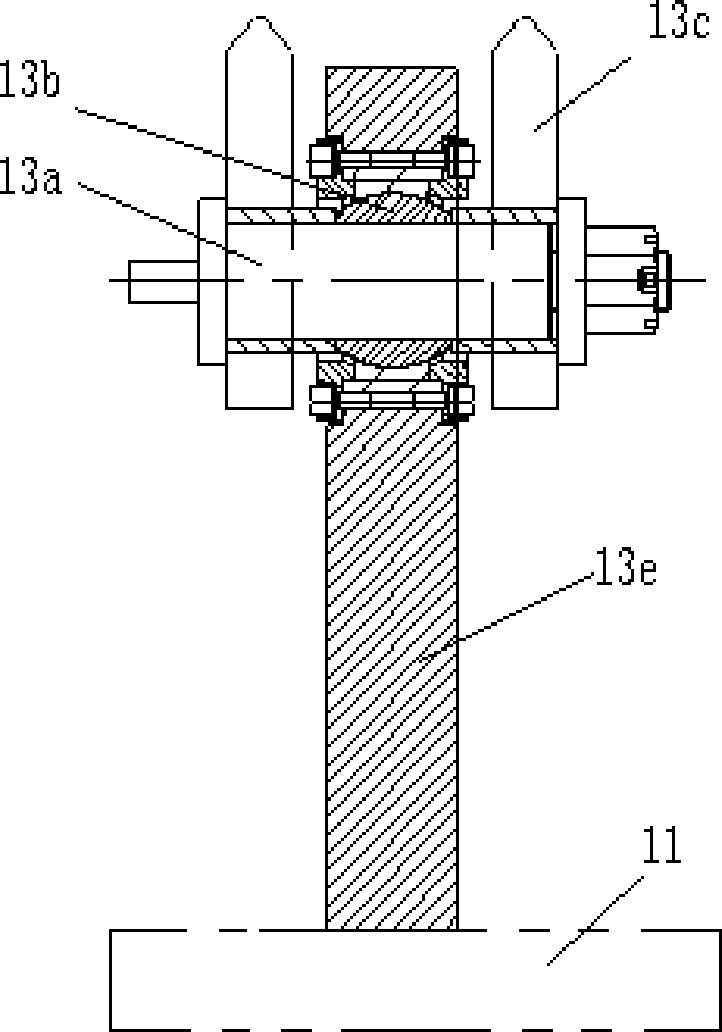

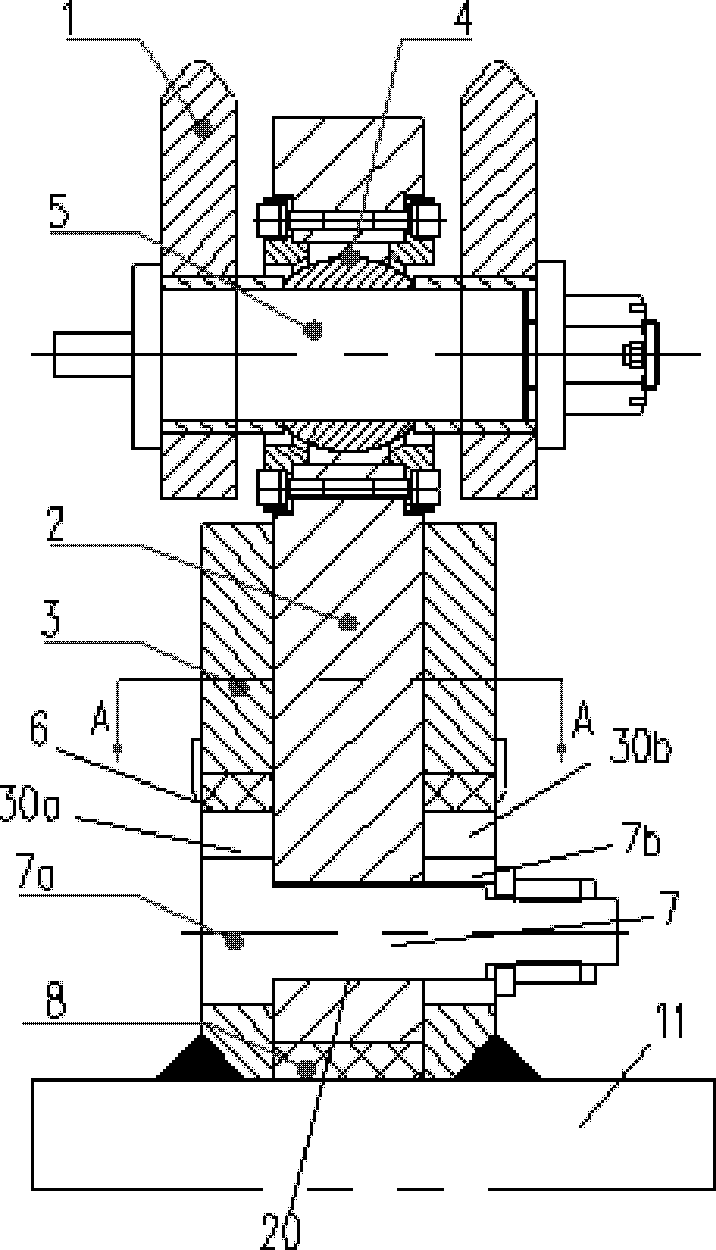

[0037] like figure 1 As shown in the sectional view of an embodiment of the anti-overturning device of the container reach stacker of the present invention, the anti-overturning device of the container reach stacker of the present invention includes: a first bracket 13 arranged between the vehicle frame and the rear axle of the lifter And the second bracket 14, the sensor 10, the controller, the vehicle frame and the rear axle are hinged to each other through the first bracket and the second bracket, and the second bracket includes a moving pair up and down. When dangerous, the rear part of the frame will be upturned, the rear axle will rotate around the hinge point of the first bracket under the action of its own weight, relative movement will occur between the up and down moving sub-components, and the sensor will detect the up and down movement The secondary movement signal is sent to the controller, and the controller controls the boom of the hoist to stop extending and li...

Embodiment 2

[0052] like Image 6 As shown, the diameter of the middle part of the third pin shaft 7 in this embodiment is larger than the diameter of both ends; the through holes 30a and 30b on the rear axle box body 3 are installed with a stop block 7c used to stop the middle part of the third pin shaft , the stop block 7c can be fixed at any position in the through holes 30a, 30b, so as to reduce the opening width of the through holes 30a, 30b, so that the opening width of the through holes 30a, 30b is smaller than the middle diameter of the third pin shaft, so as to prevent the opening width of the third pin shaft. Tripod shaft 7 escapes from through hole 20 .

[0053] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com