High strength aluminum alloy for electronic product shell and preparation method of high strength aluminum alloy

An electronic product and aluminum alloy technology, which is applied in the field of aluminum alloy processing, can solve problems such as high cost, failure to meet consumers' requirements for electronic product appearance decoration, and gray oxide film, so as to inhibit grain growth and improve oxidation. Coloring effect, de-inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

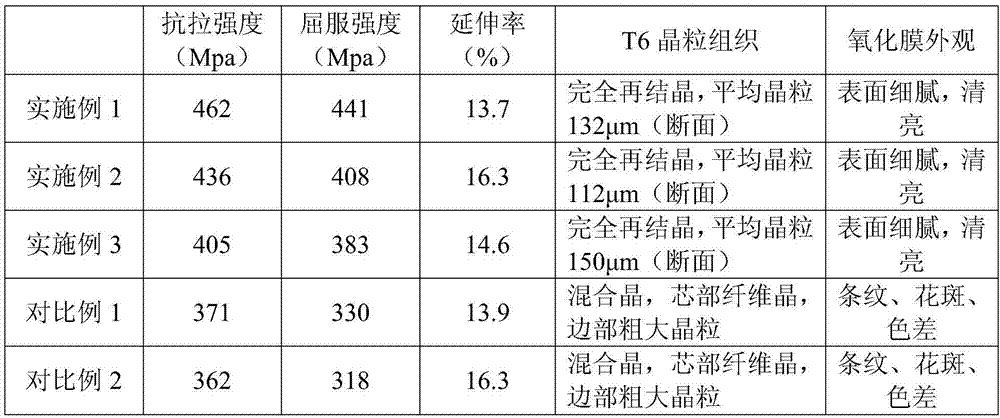

Examples

Embodiment 1

[0053] 1. The chemical composition of high-strength aluminum alloys for electronic product casings is calculated by mass percentage: Zn 6.18%, Mg 1.32%, Cu 0.12%, Ti 0.015%, B 0.0007%, Fe<0.06%, Si<0.06%, and the rest The amount is Al and other unavoidable impurities; wherein, the individual content of other unavoidable impurities is <0.01%, and the total amount of other unavoidable impurities is <0.05%.

[0054] 2. The preparation method of the high-strength aluminum alloy for the housing of the electronic product comprises the following steps:

[0055] The first step: select aluminum ingots with a purity of ≥99.9%, zinc ingots with a purity of ≥99.95%, magnesium ingots with a purity of ≥99.95%, and Al-20Cu alloys, Al-5Ti-0.2B alloy rods (grain refiners) as raw materials;

[0056] Step 2: Heat and melt the aluminum ingot at 740-745°C, add 6.18% zinc ingot, 1.32% magnesium ingot and 0.12% Al-20Cu alloy accounting for the total weight of the raw materials, stir and melt to for...

Embodiment 2

[0066] 1. The chemical composition of high-strength aluminum alloys for electronic product casings is calculated by mass percentage: Zn 6.8%, Mg 1.24%, Cu 0.35%, Ti 0.029%, B 0.0012%, Fe<0.08%, Si<0.04%, and the rest The amount is Al and other unavoidable impurities; wherein, the individual content of other unavoidable impurities is <0.01%, and the total amount of other unavoidable impurities is <0.05%.

[0067] 2. The preparation method of the high-strength aluminum alloy for the housing of the electronic product comprises the following steps:

[0068] The first step: select aluminum ingots with a purity of ≥99.9%, zinc ingots with a purity of ≥99.95%, magnesium ingots with a purity of ≥99.95%, and Al-20Cu alloys, Al-5Ti-0.2B alloy rods (grain refiners) as raw materials;

[0069] The second step: heating and melting the aluminum ingot at 760°C, adding 6.8% zinc ingot, 1.24% magnesium ingot and 0.35% Al-20Cu alloy accounting for the total weight of raw materials, stirring and...

Embodiment 3

[0078] 1. The chemical composition of high-strength aluminum alloys for electronic product casings is Zn 6.5%, Mg 1.6%, Cu 0.25%, Ti 0.020%, B 0.0010%, Fe<0.10%, Si<0.06%, and the balance It is Al and other unavoidable impurities; wherein, the individual content of other unavoidable impurities is <0.01%, and the total amount of other unavoidable impurities is <0.05%.

[0079] 2. The preparation method of the high-strength aluminum alloy for the housing of the electronic product comprises the following steps:

[0080] The first step: select aluminum ingots with a purity of ≥99.9%, zinc ingots with a purity of ≥99.95%, magnesium ingots with a purity of ≥99.95%, and Al-20Cu alloys, Al-5Ti-0.2B alloy rods (grain refiners) as raw materials;

[0081] Step 2: Heat and melt the aluminum ingot at 750-755°C, add 6.5% zinc ingot, 1.6% magnesium ingot and 0.25% Al-20Cu alloy accounting for the total weight of raw materials, stir and melt to form aluminum alloy liquid;

[0082] The third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com