Full-automatic bolt and nut cleaning machine

A technology for bolts and nuts, cleaning machines, applied in the directions of dryers, cleaning methods and utensils, cleaning methods using tools, etc. Reasonable structure, easy to observe and easy to clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

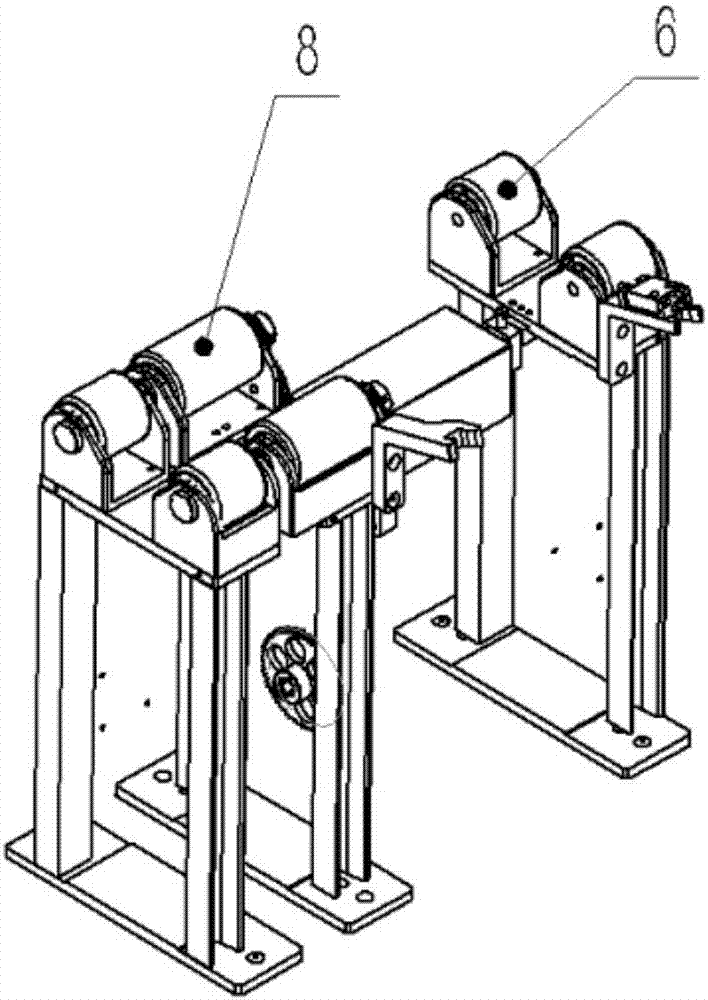

[0028] A fully automatic bolt and nut cleaning machine, including a cleaning machine main body 1, a bolt locking tilting mechanism 5 and a bolt rotating support mechanism 6 on the left side of the cleaning machine main body 1, and the bolt locking tilting mechanism 5 is a hydraulic Drive the bolts to dump and turn over, and the middle part is locked with a locking ring 7. The bolt rotation support mechanism 6 adopts a V-shaped structure composed of a pair of rubber rollers 8 and two pairs of nylon rollers. The rubber rollers 8 are driven by a motor to drive the bolts to rotate. The right end of the main body of the cleaning machine is provided with a nut disassembly and installation mechanism 10 and a nut cleaning and air-drying mechanism 12, and the nut disassembly and installation mechanism 10 is mounted on the leading screw 9, and the nut cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com