A high-efficiency food processing equipment

A food processing and high-efficiency technology, applied in food forming, plant protein processing, food science, etc., can solve the problems of cumbersome processing, inability to automatically complete the gluten processing process, and low gluten production efficiency, so as to improve the sealing effect, The effect of avoiding manual salvage and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

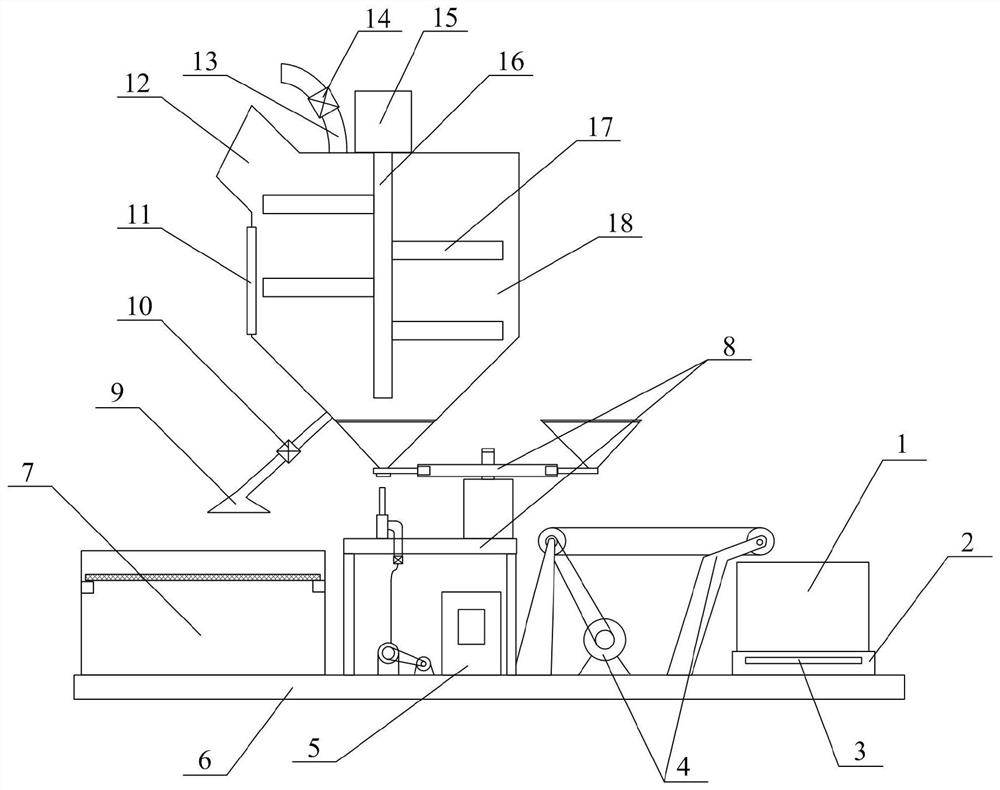

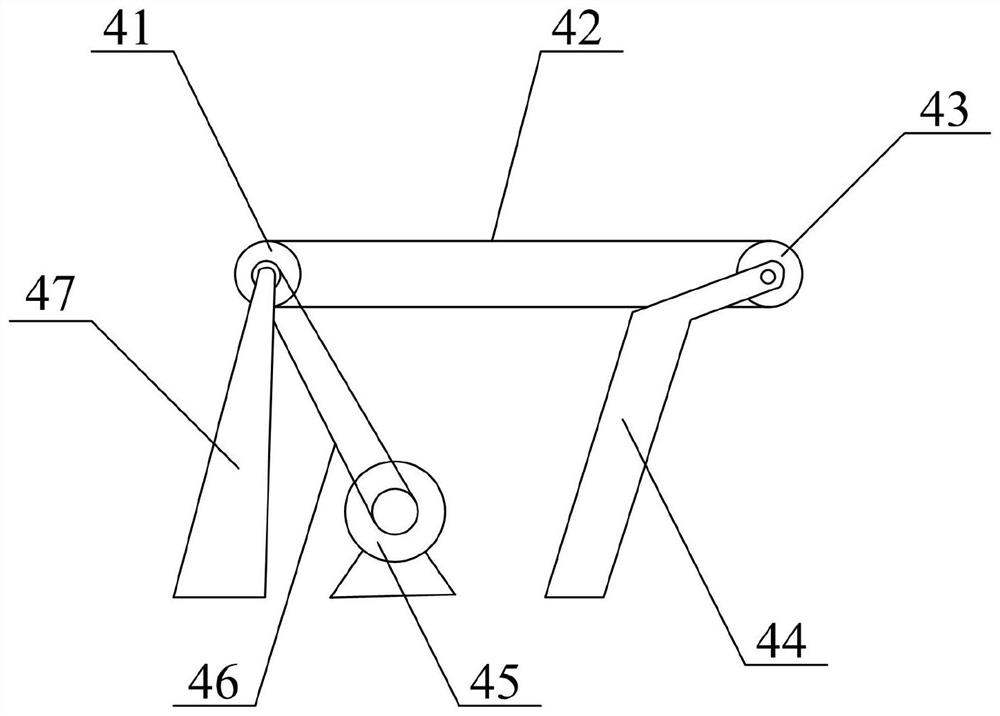

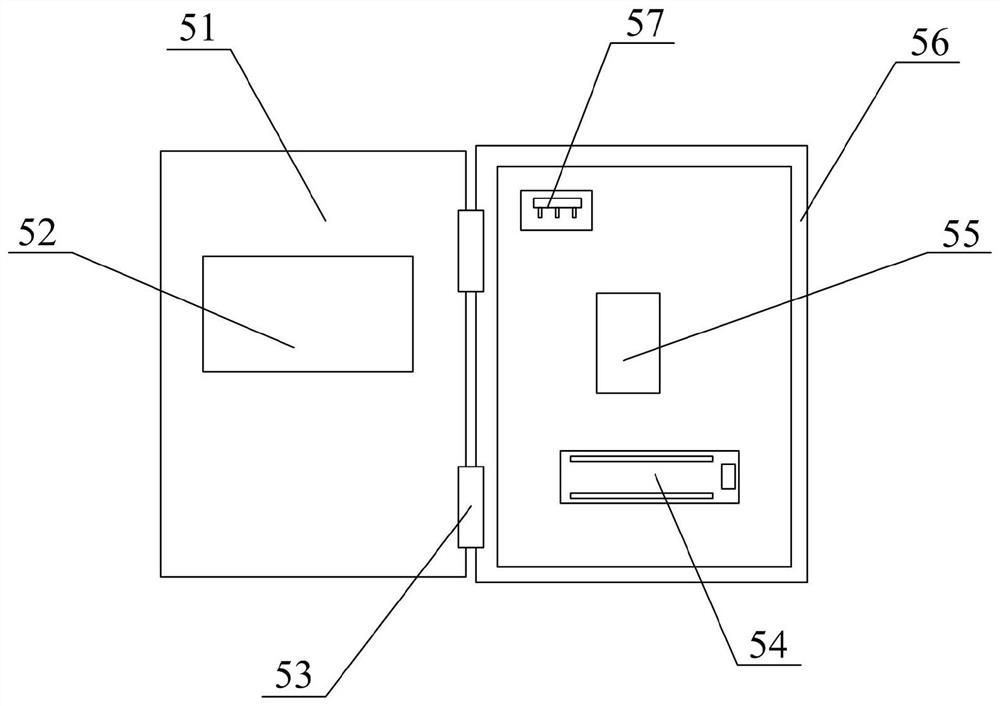

[0037] as attached figure 1 to attach Figure 6 shown

[0038]The invention provides a high-efficiency food processing equipment, which includes a cooking cylinder 1, a cooking furnace seat 2, a heating wire 3, a gluten transporting device 4, a control cabinet 5, a base 6, a cold skin filtering device 7, a gluten transporting device 8, and a drainage cover 9. Drainage valve 10, observation window 11, noodle adding port 12, water injection port 13, water adding valve 14, stirring motor 15, stirring main shaft 16, stirring paddle 17 and stirring chamber 18, and the boiler seat 2 bolts are installed on the base the upper right part of 6; the cooking tube 1 is fixed on the upper part of the cooking stove seat 2; the heating wire 3 is installed inside the cooking stove seat 2; the gluten transporting device 4 is welded on the middle and upper part of the base 6; Described Liangpi filtering device 7 bolts are installed on the left upper part of base 6; Described gluten transportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com