Controlling method for scrap steel reeling caused by head part offset at finish rolling exit

A control method and head technology, applied in metal rolling, profile control, metal rolling, etc., can solve the problems of inaccurate movement, quality fluctuation, and large coiling ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

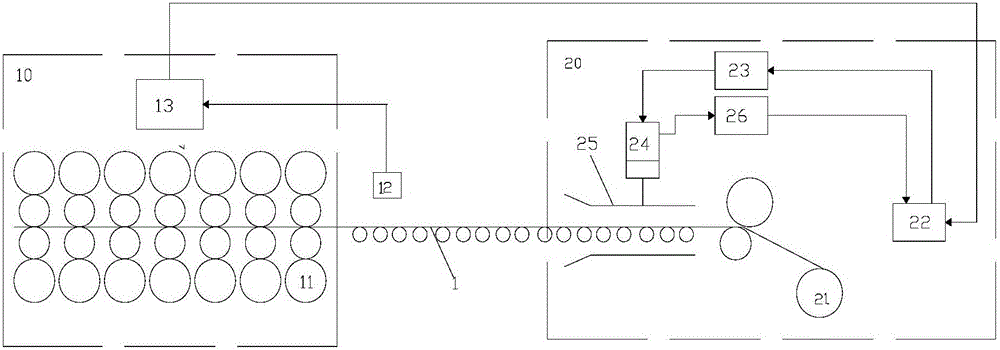

[0031] The technical solution provided by the present invention uses the actual measurement of the exit flatness deviation of the finish rolling exit flatness detection system, and sends the actual measurement value of the strip head deviation to the coiling side guide plate control system, according to the actual measurement value. Use the opening amount of the side guide plate to implement precise control.

[0032] 1. The specific hardware configuration consists of a flatness detection system and a winding side guide control system.

[0033] Straightness detection system: This system is mainly used to detect the actual strip shape of the strip head after finishing rolling F7.

[0034] Coiling side guide plate control system: This system is mainly used for the position control of the side guide plate. The control system calculates the setting value of the side guide opening according to the control model.

[0035] 2. The grading of the wave shape detection value of the flatness mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com