Lithographic Printing Original Plate, Method For Producing Lithographic Printing Plate Using Same, And Method For Producing Printed Matter

A lithographic printing plate and manufacturing method technology, applied in lithographic printing equipment, flatbed printing presses, printing and other directions, can solve the problem of lack of printing resistance, and achieve the prevention of dirty plate, printing resistance and reproduction of tiny dots good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

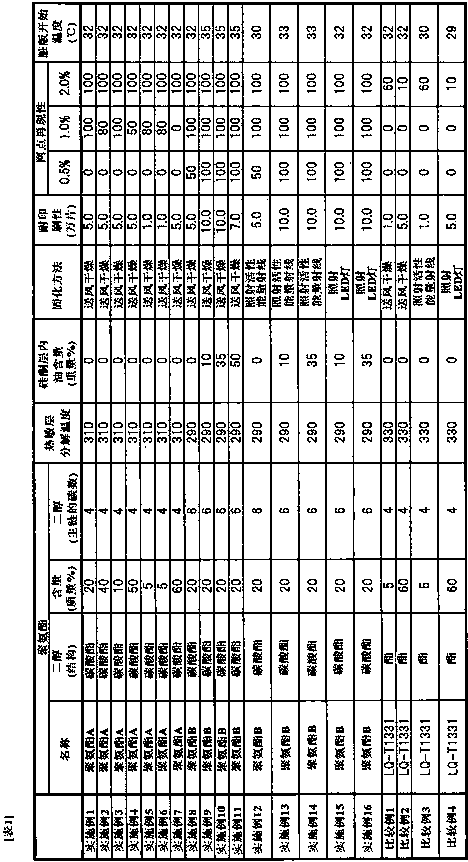

Examples

Embodiment

[0150] Hereinafter, the present invention will be described in further detail using examples. Evaluation in each Example and Comparative Example was performed by the following method.

[0151] (1) TEM observation of the original lithographic printing plate

[0152] Samples were prepared from the original lithographic printing plate before laser irradiation by the ultrathin section method. Using a transmission electron microscope: Model H-1700FA (manufactured by Hitachi High Technologies Co., Ltd.), the cross-section of the heat-sensitive layer was observed at an accelerating voltage of 100 kV and a magnification of 2000 times. The average film thicknesses of the protective film, the silicone rubber layer, the thermosensitive layer, and the heat insulating layer were measured by the method described below.

[0153] (1-1) Average film thickness of protective film, silicone rubber layer, heat-sensitive layer, and heat-insulating layer

[0154] For 10 positions randomly selecte...

Embodiment 6

[0164] However, only Example 6 was developed under the following conditions.

[0165] Pretreatment solution (45°C): CP-Y (manufactured by Toray Co., Ltd.)

[0166] Developer solution (room temperature): tap water

[0167] Post-treatment fluid (room temperature): tap water

[0168] Passing speed: 80cm / min.

[0169] In the printing plate obtained by exposure and development, check the number of peeled silicone rubber layers of each halftone dot. The larger the number of peeled silicone rubber layers, the better the halftone dot reproducibility is judged. When the reproducibility of 4 dots is 100% or more , judged to be practically applicable.

[0170] (3) Printing conditions

[0171] (3-1) Oily printing

[0172] The printing plate obtained by the method described in the above (2-2) was mounted on an offset printing machine Komori Sprint 4-color machine (manufactured by Komori Corporation), and "Alpo" (registered trademark) manufactured by T&K TOKA was used. ) GT, for print...

Synthetic example 1

[0186] (Synthesis Example 1) Synthesis of Polyurethane A

[0187] 100 parts by mass of ethylene carbonate and 100 parts by mass of 1,4-butanediol were placed in the glass flask while introducing nitrogen gas into a glass round bottom flask equipped with a rectification tower, a stirrer, a thermometer, and a nitrogen introduction tube. parts, 20 parts by mass of 1,6-hexanediol, while adding 0.02 parts by mass of titanium tetrabutoxide as a catalyst, while mixing at room temperature to make the system uniform, gradually increase the temperature in the system from 150°C to The reaction was carried out for 20 hours while raising the temperature to 160°C. Thereafter, the pressure was reduced to 0.5 kPa, and the reaction was further performed at 170° C. for 10 hours while distilling diol and ethylene carbonate, thereby obtaining polycarbonate diol A (number average molecular weight: 2000) having 4 main chains.

[0188] 200 parts by mass of polycarbonate diol A, 1,4-butanediol (Wako...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com