Fuel Additives to Reduce Greenhouse Gases, Nitrogen Oxide and Particulate Matter

A fuel additive and fuel oil technology, applied in fuel additives, liquid carbon-containing fuels, fuels, etc., can solve problems such as increased maintenance costs, and achieve the effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention is further described in detail through examples. The following examples are only used to more clearly illustrate the technical characteristics of the present invention, and are not intended to limit the scope of protection of the present invention.

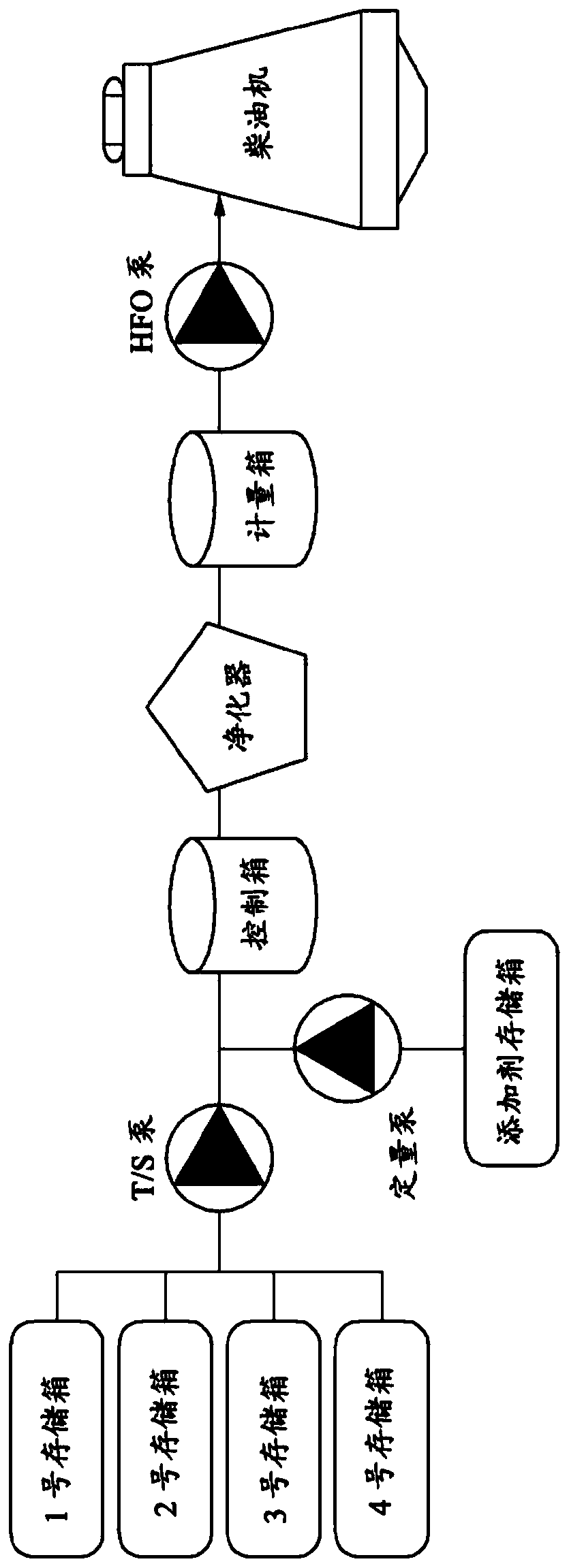

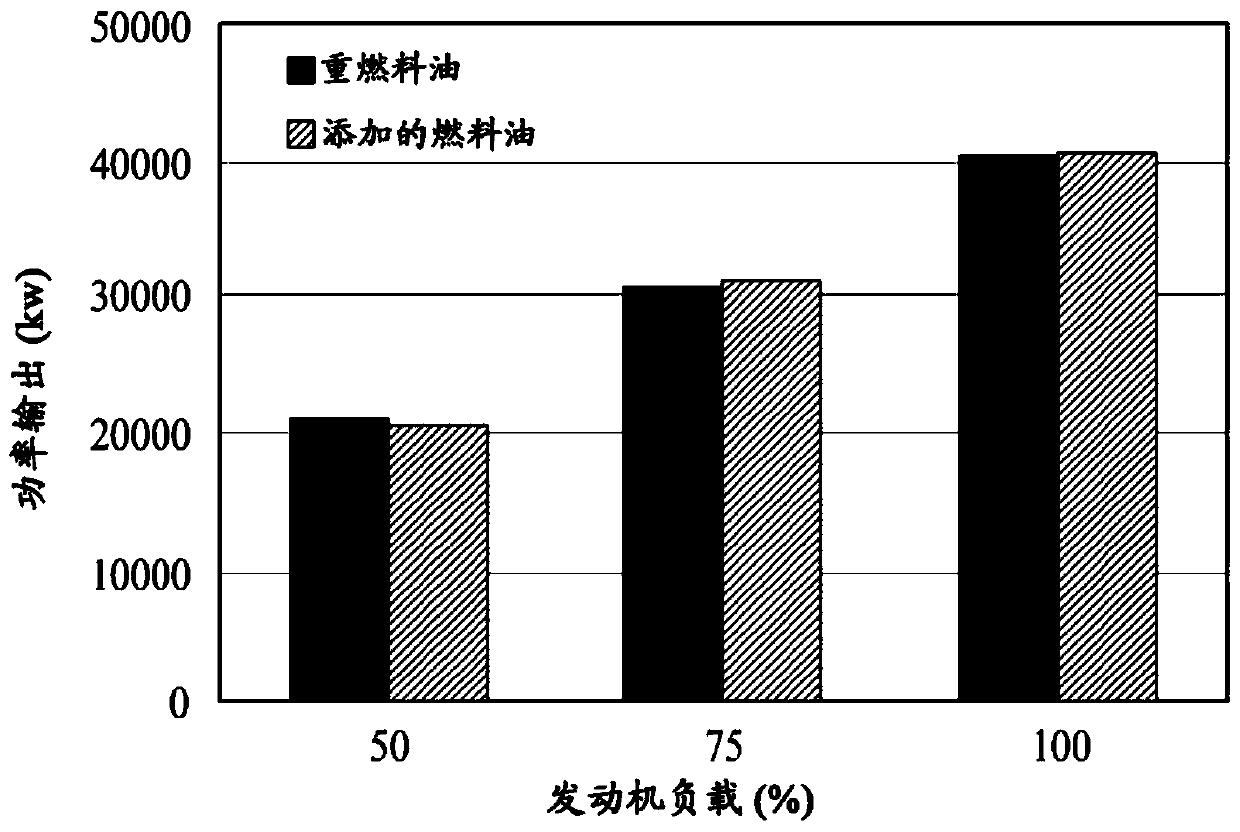

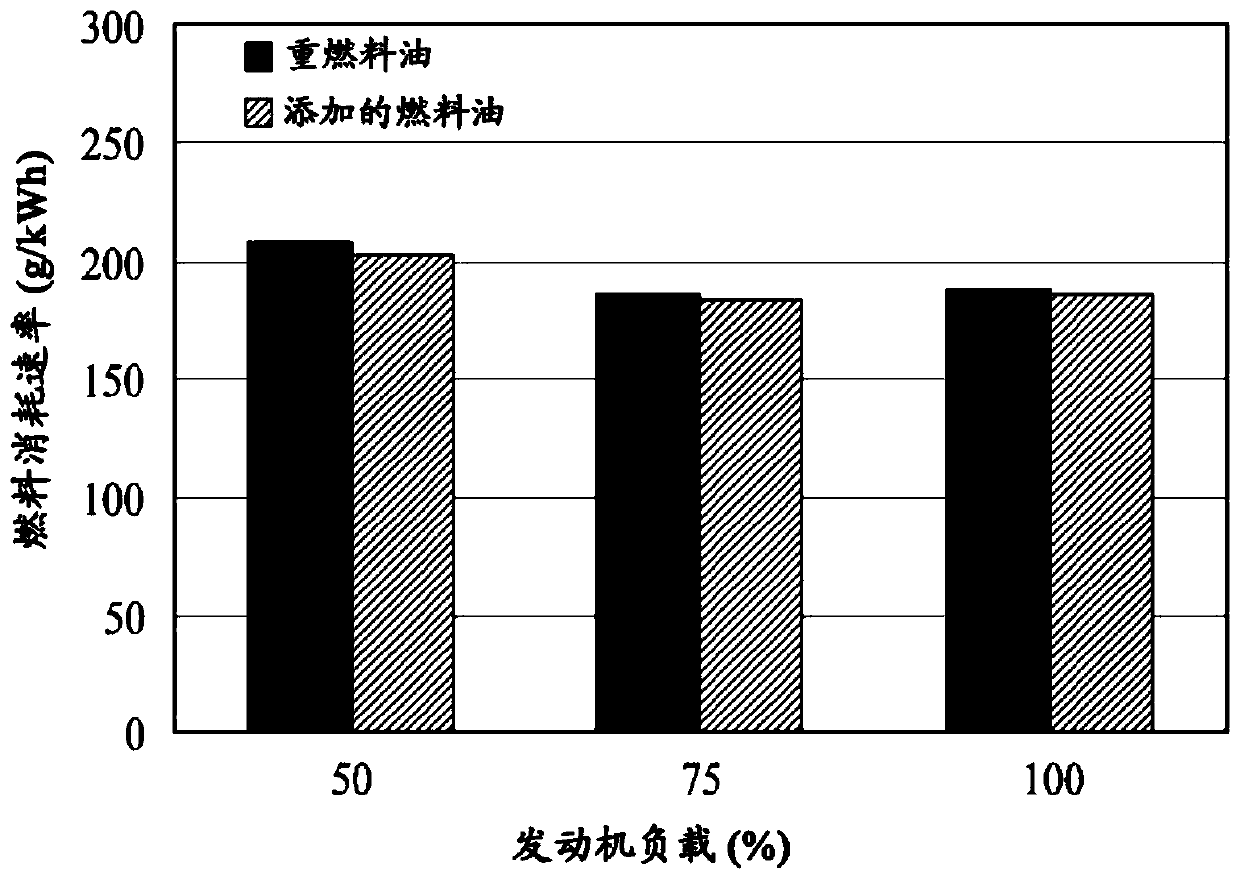

[0045] In order to save fuel costs, the applicant of the present invention dosed a given fuel additive containing an oil-soluble calcium-based organometallic compound as a component into heavy oil used for ships. More specifically, a certain amount (0.025% of the amount of fuel used) of a given fuel additive (containing an oil-soluble calcium-based organometallic compound therein as a component) was dosed in order to study fuel cost savings. In order to ensure the accuracy of the test, a two-stroke giant diesel engine installed in a land thermal power plant was put into use as a test product. For the load of the test engine, it is divided into low, medium and high (50, 75, 100%) three gear load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com