High-voltage equipment box of D-series high-speed train

A technology for high-voltage equipment boxes and EMUs, which is applied in the field of rail vehicles, can solve problems such as adverse wind resistance performance of EMUs, reduced insulation capacity, and component explosions, and achieve the effects of avoiding quality accidents, improving insulation capacity, and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

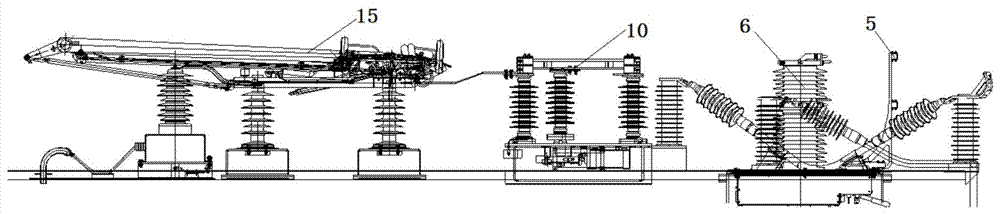

[0028] Such as Figure 2-Figure 5 As shown, the present invention first discloses a high-voltage equipment box for an EMU, which is installed on the top of the EMU, and the equipment box includes a box body 1 and an incoming cable terminal 2 and a lightning arrester 7 arranged in the box body 1 , Go to transformer cable terminal 8, high voltage isolating switch 10, go to other car cable terminal 11, vacuum circuit breaker 6 and high voltage grounding switch 5.

[0029] In this embodiment, the box body 1 includes two opposite first side walls 101, second side walls 102, third side walls 103, and fourth side walls 104; The transformer cable terminal 8 is arranged on the first side wall 101, the high-voltage isolation switch 10 is arranged on the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com