Mould made for simulating multi-scale natural rock structure surfaces

A structural surface and multi-scale technology, applied in the engineering field, can solve the problems of poor fit between the original rock structural surface and the lower wall, high sampling cost, and difficulty in obtaining the original rock structural surface, etc., to achieve easy assembly and disassembly, simple mold structure, The effect of overcoming experimental error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

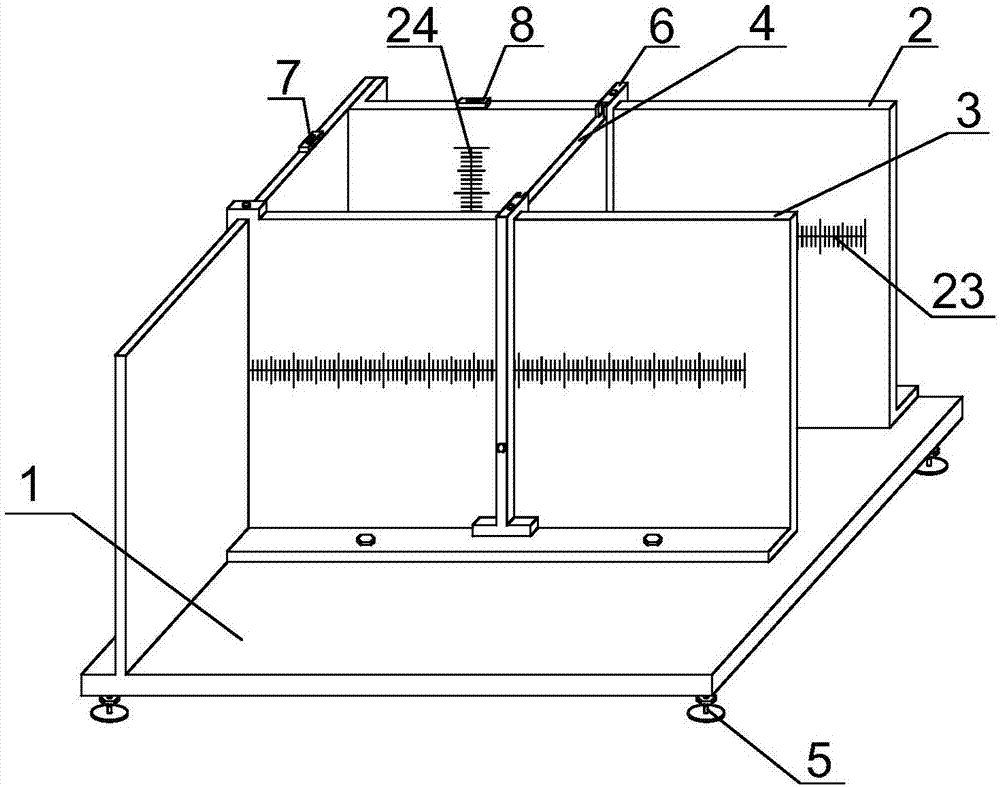

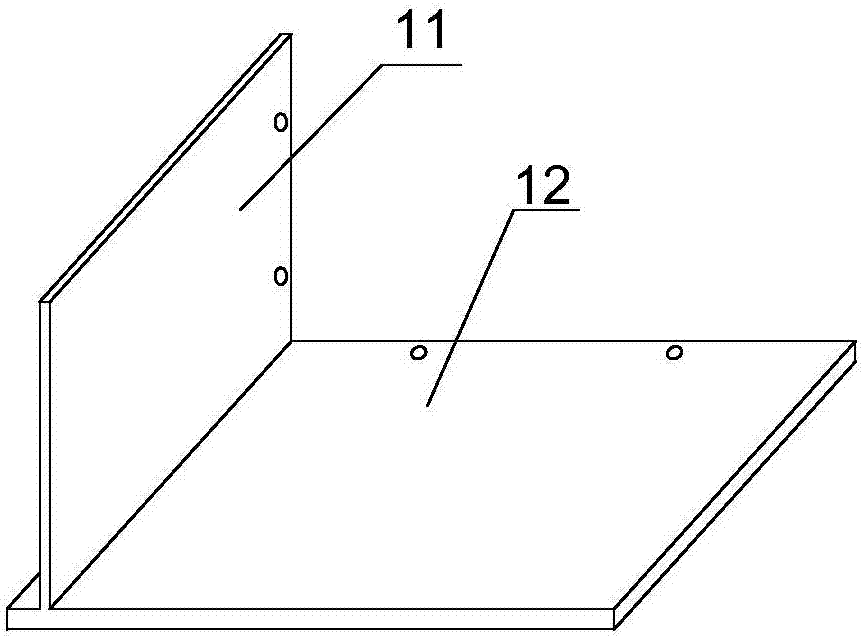

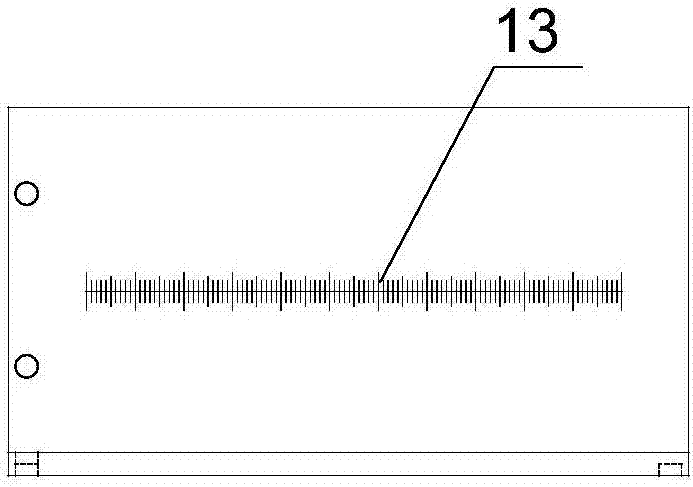

[0030] Please refer to figure 1 , figure 2 and image 3 , an embodiment of the present invention provides a mold for making a simulated multi-scale natural rock mass structural surface, including a bottom plate 1 and a fixed side plate 2, and the bottom plate 1 includes a lower platform 12 and a side wall perpendicular to the lower platform 12 11. Four adjustable supports 5 arranged in a rectangle are installed on the lower surface of the lower platform 12, and a first scale 13 perpendicular to the fixed side plate 2 is provided on the outer side of the side wall 11. The wall 11 is also provided with a first leveler 7, the fixed side plate 2 is vertically and detachably fixed to the bottom plate 1 and vertically connected with the side wall 11, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com