Cold supply system and control method thereof

A control method and technology of a cooling system, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of insufficient cooling, destruction of refrigerant circulation pipelines, and high pressure, so as to reduce pipeline pressure and protect damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] One of the cores of the present invention is to provide a cooling system so that on the one hand it can meet the cooling demand and on the other hand it can avoid system damage caused by excessive pressure on the low-pressure side of the system.

[0029] Another core of the present invention is to provide a control method for the above-mentioned cooling system.

[0030] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

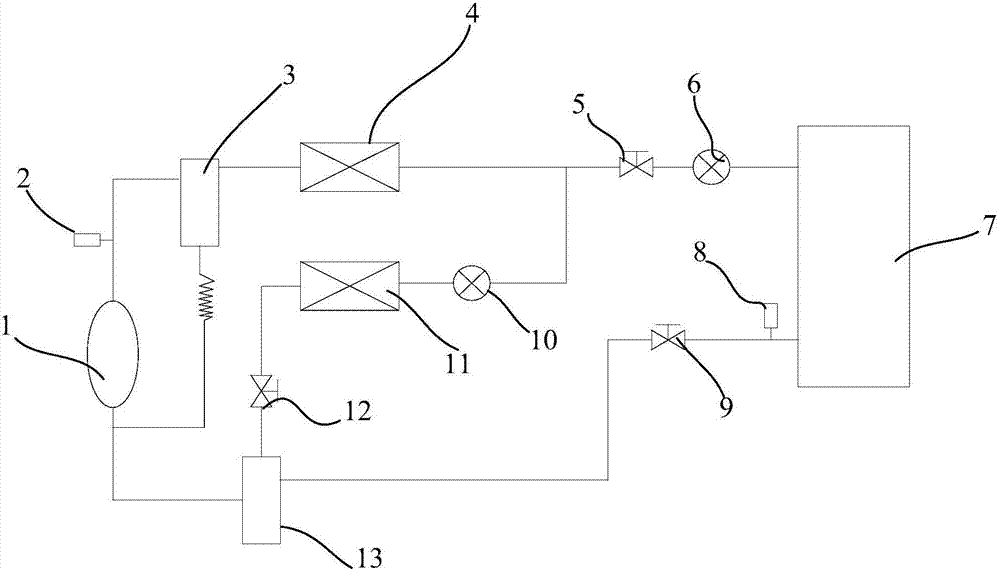

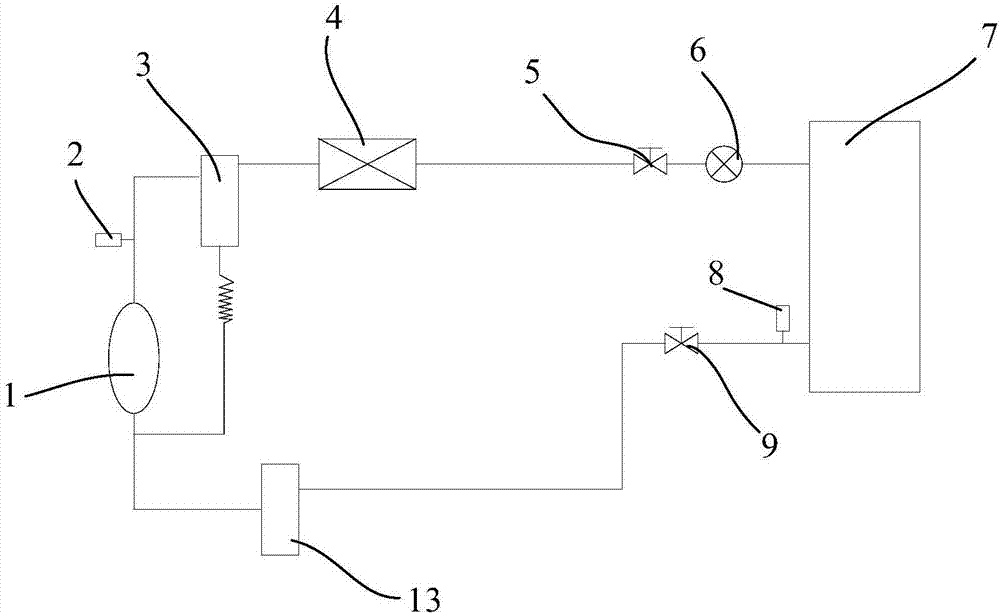

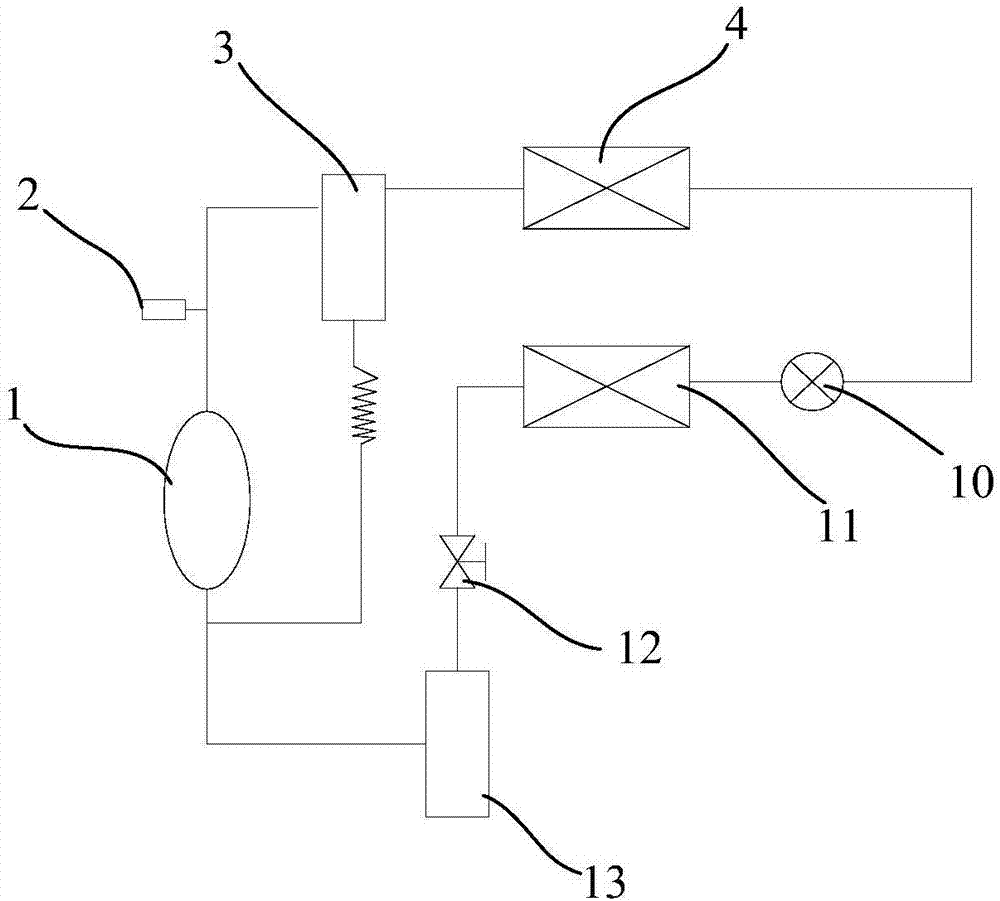

[0031] Please refer to figure 1 , the cooling system disclosed in the present invention includes a common flow path, an auxiliary operation branch and a main operation branch connected in parallel with the auxiliary operation branch. Different, multiple main operation branches can also be set; the common flow path includes the compressor 1 and the condenser 4 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com